What is Torque Motor?

A torque motor is a special type of electric motor designed to produce high torque at very low speeds, including the ability to hold torque at zero speed. Unlike many common motors that are built to spin fast and then use gears to increase torque, a torque motor is built to deliver strong rotational force directly at the shaft. This direct force is extremely useful when a system needs smooth motion, accurate positioning, steady holding power, and fast response without mechanical complexity.

In simple words, torque is the twisting force that turns something. A torque motor focuses on creating that twisting force in a controlled way. Many torque motors are used in direct drive setups, meaning the motor connects straight to the load with no gearbox, belt, or chain. This reduces backlash, reduces mechanical noise, and improves motion accuracy. In cinema and cinematic electronics, these advantages matter a lot because cameras, lenses, gimbals, motion platforms, and focus systems need stable, precise, silent, and repeatable movement.

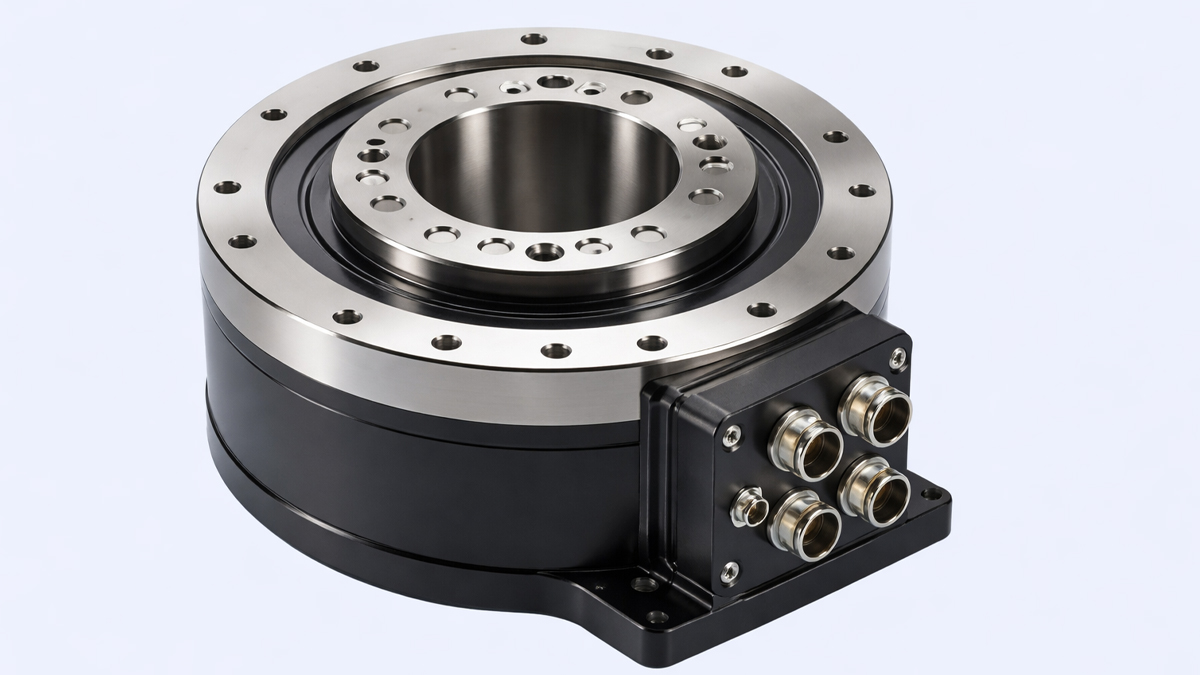

Torque motors are commonly built as brushless motors and often look different from everyday motors. Some are ring-shaped, some are large diameter motors with a hollow shaft, and some are compact motors integrated into a mechanism. What makes them stand out is their ability to provide controlled torque over a wide range of speeds, especially near zero speed, while staying smooth and stable.

How does Torque Motor Work?

A torque motor works by converting electrical energy into rotational force through electromagnetic interaction between a stationary part and a rotating part. The stationary part is usually called the stator, and it contains coils that create a magnetic field when current flows through them. The rotating part is called the rotor, and it usually carries permanent magnets or an electromagnetic structure. When the stator coils are energized in a controlled sequence, the magnetic fields attract and repel the rotor magnets, producing torque.

Control system role: The torque motor is usually paired with a motor controller and feedback sensors. The controller decides how much current to send into the motor phases. The amount of current is directly linked to torque. More current generally means more torque. This is why torque motors are excellent for controlled force applications.

Feedback and precision: Most torque motor systems use encoders or resolvers to measure rotor position and speed. This feedback helps the controller correct errors instantly. When the motor is part of a camera stabilizer or a robotic camera head, the feedback loop keeps motion smooth and accurate even if the load changes.

Zero speed holding: A major advantage of a torque motor is that it can hold a position without moving, while still applying torque. For example, if a camera rig needs to hold a tilt angle steadily against imbalance or wind, the torque motor can apply just enough torque to keep the rig locked without drifting.

Direct drive behavior: In direct drive systems, there is no gearbox to multiply torque. So the motor itself is designed with a larger diameter, stronger magnets, or more coil surface area to produce high torque directly. The result is very smooth motion with minimal mechanical artifacts, which is ideal for cinema movement.

What are the Components of Torque Motor?

A torque motor system includes both the motor hardware and the supporting electronics that make it perform like a precision torque source. The exact design changes by manufacturer and application, but the core elements remain similar.

Stator core and windings: The stator is the stationary part. It contains laminated steel or a similar magnetic core and copper windings. The windings are arranged to create a rotating magnetic field when powered. A torque motor often has windings optimized for high torque and thermal stability.

Rotor and magnets: The rotor is the moving part. Many torque motors use permanent magnets on the rotor. These magnets are arranged to interact efficiently with the stator field. High-quality magnet materials help increase torque density and improve response.

Air gap and magnetic circuit: The air gap is the small space between stator and rotor. It must be manufactured with precision. A stable air gap supports smooth torque production and reduces cogging effects. The magnetic circuit includes all magnetic paths that guide flux through the motor.

Bearings and support structure: Bearings support rotation and maintain alignment. In cinema applications, low noise and low vibration bearings are important. Some high-end systems use specialized bearings to reduce runout and improve stability.

Housing and thermal path: Torque motors can produce heat because torque requires current and current generates heat in windings. The housing is often designed to move heat away from the windings into the chassis. Good thermal design helps maintain torque performance during long shooting days.

Position feedback device: Many torque motor systems include an encoder, resolver, or magnetic sensor to measure position. This feedback is vital for smooth motion and repeatability. In cinematic robotics, accurate position feedback is essential for motion control and repeat takes.

Motor controller or drive: The controller supplies the correct phase currents and manages torque, speed, and position loops. In torque mode, the controller focuses on regulating current precisely. High-quality control algorithms reduce ripple, reduce noise, and improve stability.

Cables and connectors: In cinematic electronics, cable management matters. Flexible cables, reliable connectors, and shielding help prevent interference, signal noise, and sudden failures during production.

What are the Types of Torque Motor?

Torque motors come in different forms based on design, control method, and application needs. The types below describe the most common categories seen in industry and in cinematic systems.

Direct drive torque motors: These are designed to connect directly to the load without a gearbox. They are often large diameter motors, sometimes with hollow shafts. They are widely used in robotic joints, gimbals, pan tilt heads, and precision stages.

Frameless torque motors: Frameless designs are supplied as a stator and rotor kit without a housing or bearings. They are meant to be built into a machine structure. In cinema robotics and high-end stabilizers, frameless torque motors allow compact integration and custom mechanical design.

Brushless torque motors: Many modern torque motors are brushless and use electronic commutation. Brushless designs provide high efficiency, long life, and low maintenance. They also offer smoother torque control compared to brushed motors.

Brushed torque motors: Some torque motors use brushes and commutators. They can be simpler to control and can deliver strong torque at low speed, but they often create more electrical noise, require maintenance, and may be less ideal for silent cinema environments.

AC torque motors: Some torque motors are designed for AC drives, often in industrial settings. They can provide strong torque and precise control when paired with suitable drives. In cinema, brushless DC style systems are more common, but AC torque motors can still appear in specialized rigs.

Servo torque motors: Many torque motors are used as part of a servo system where feedback and control create a closed loop. Servo torque motors are common in camera motion control, lens control systems, and robotic camera arms.

Hollow shaft torque motors: These motors have a center opening to route cables, slip rings, optical paths, or mechanical shafts. This is useful in pan axes where cables must pass through the rotation center without snagging.

What are the Applications of Torque Motor?

Torque motors are used anywhere that needs smooth control, strong low-speed force, high accuracy, and stable holding. Their direct drive nature makes them especially valuable in precision motion systems.

Industrial robotics: Robot joints often need high torque at low speed with accurate positioning. Torque motors provide smooth motion, reduce backlash, and improve repeatability.

Precision positioning stages: In optics, metrology, and manufacturing, torque motors can position loads precisely without gear backlash. This is similar to how cinematic motion control needs repeatable camera paths.

Aerospace and defense systems: Torque motors can control gimbals, antenna pointing, sensor platforms, and stabilization systems.

Medical equipment: Imaging devices and surgical tools can use torque motors for smooth and precise motion with low noise and high reliability.

Automated manufacturing: Torque motors can drive rotary tables, indexing heads, and direct drive spindles where precision matters.

Cinematic electronics and film equipment: Torque motors are used in gimbals, stabilized heads, motion control rigs, robotic camera arms, lens control modules, and special effects platforms. They help create smooth camera movement and precise control that looks natural on screen.

What is the Role of Torque Motor in Cinema Industry?

In the cinema industry, motion quality is part of storytelling. A small jitter, a harsh start, a noisy motor, or a drifting camera angle can ruin a shot. Torque motors support cinematic quality by enabling smooth, controlled, repeatable, and quiet movement across many types of equipment.

Camera stabilization and gimbals: Gimbals need motors that react quickly and smoothly to changes in camera orientation. Torque motors, especially brushless direct drive types, can apply precise torque to keep the camera level and stable. This helps achieve floating movement and removes shaky motion during handheld shooting.

Pan tilt heads and remote heads: Professional heads used on cranes, dollies, and tripods need controlled movement for pan and tilt. Torque motors allow very slow creeping moves as well as faster dynamic moves, all with smooth acceleration and deceleration.

Motion control systems: Motion control is used for VFX plates, product shots, miniatures, and repeatable camera paths. Torque motors help motion control rigs repeat the same move with high accuracy. This is essential when combining multiple passes, such as clean plate, effects pass, and lighting variations.

Robotic camera arms: Robotic systems rely on strong torque, smooth control, and precision. Torque motors integrated into joints help achieve natural arcs, stable stops, and repeatable paths. This improves safety and reduces mechanical wear compared to gear-driven systems.

Lens control and focus systems: While lens motors are often smaller, torque motor principles still apply when a system needs smooth torque at low speed for focus pulls, iris control, or zoom moves. A stable torque response helps create smooth focus transitions that match a cinematographer’s intent.

Silent operation on set: Audio capture is often happening during filming. Torque motors can be designed for low noise and low vibration, reducing the risk of motor noise being recorded.

Natural motion feel: The best cinema motion feels organic. Torque motors allow control profiles that mimic natural movement, such as gentle starts, smooth ease-out stops, and stable holds. This creates a premium look without distracting mechanical artifacts.

What are the Objectives of Torque Motor?

The objectives of a torque motor depend on the system it supports, but the main goal is always controlled torque delivery with stability and precision. In cinematic electronics, these objectives align closely with creative and production needs.

High torque at low speed: Provide strong rotational force even when moving slowly or not moving at all. This supports stable holds and slow camera moves.

Smooth torque output: Reduce torque ripple and reduce cogging so movement looks fluid. Smoothness is critical for camera motion and stabilization.

Accurate control and repeatability: Work with feedback sensors to achieve precise positioning and repeatable motion paths for multiple takes and VFX workflows.

Fast dynamic response: React quickly to changes in load or control commands. This helps stabilization systems correct motion instantly and helps robotic rigs follow motion profiles accurately.

Reduced mechanical complexity: Enable direct drive designs that remove gearboxes, belts, and chains. This reduces backlash, reduces maintenance, and improves reliability.

Low noise and low vibration: Support on-set audio recording and prevent micro vibrations that can appear as jitter in high-resolution footage.

Efficiency and thermal stability: Maintain performance over long shoots without overheating. Thermal stability supports consistent torque output and protects electronics.

What are the Benefits of Torque Motor?

Torque motors provide a combination of performance and reliability benefits that are difficult to achieve with traditional geared motor systems, especially in cinema-grade equipment.

Direct drive precision: Without a gearbox, there is minimal backlash. This improves accuracy in pan, tilt, and robotic motion.

Smooth motion quality: Torque motors are excellent for slow, continuous motion. This supports cinematic camera moves that feel polished and intentional.

Strong holding capability: The motor can hold a position with controlled torque. This helps keep cameras stable on cranes, rigs, and stabilizers.

Reduced maintenance: Brushless torque motors have fewer wear parts compared to brushed motors and gear-driven systems. This improves uptime during production schedules.

Compact integration options: Frameless torque motors allow custom mechanical designs that save space and weight. This matters for handheld rigs and drone payloads.

Better repeatability for VFX: Repeat moves are essential for compositing and multi-pass shots. Torque motors support accurate replication of camera paths.

Lower mechanical noise: Removing gears reduces audible noise and reduces vibration. This helps both audio quality and image stability.

Improved safety and control: Torque control allows gentle force limiting, smoother stops, and better handling of unexpected load changes. This is useful in robotic camera systems near crew and talent.

What are the Features of Torque Motor?

Torque motors have design and performance features that make them suitable for precision motion and cinematic electronics.

High torque density: Designed to produce strong torque relative to size, often using powerful magnets and optimized winding structures.

Low speed stability: Maintain smooth rotation at extremely low speeds, even near zero speed, which is vital for slow pans and tilt moves.

Torque mode control: Many systems support true torque control through precise current regulation, enabling consistent force output.

High resolution feedback compatibility: Works with encoders and resolvers for accurate position and speed feedback, improving smoothness and repeatability.

Low backlash by design: Direct drive eliminates gear backlash, which reduces positioning errors and improves shot consistency.

Good thermal design options: Many torque motors are designed to be mounted into metal structures that act as heat sinks, supporting long continuous operation.

Hollow shaft availability: Many torque motors include a hollow center for cable routing, making them ideal for rotating heads and gimbals.

Low cogging options: Premium torque motors use slotless or optimized magnetic designs to reduce cogging and improve smoothness, which matters for cinema motion.

What are the Examples of Torque Motor?

Examples of torque motor usage can be understood through real-world equipment categories used in cinematic electronics and related motion control fields.

Camera gimbal axis motors: Many professional gimbals use brushless direct drive torque motors on roll, pitch, and yaw axes to keep the camera stable and responsive.

Remote pan tilt heads: High-end remote heads used on cranes and vehicles often use torque motors for smooth pan and tilt performance with repeatable control.

Robotic camera systems: Cinema robotic arms and motion platforms use torque motor driven joints or direct drive rotary axes for accurate movement and programmed repeat takes.

Turntables and product rigs: Product cinematography often uses precision turntables that rotate slowly and smoothly. Torque motors are ideal here due to low speed stability.

Virtual production and tracking rigs: Some tracking and positioning systems use torque motor driven rotary stages to align sensors, cameras, or reflective marker assemblies precisely.

Lens control modules: Certain focus and zoom systems use torque-controlled motors to deliver smooth pulls and stable holds, especially when paired with feedback.

Stabilized vehicle mounts: Car rigs and vibration isolation platforms can include torque motors to actively correct orientation or to control stabilized head movement.

What is the Definition of Torque Motor?

A torque motor is an electric motor designed primarily to deliver controlled torque, especially at low speeds and at zero speed, often as part of a direct drive system with precision feedback control. The definition emphasizes torque output and control quality rather than high-speed operation.

What is the Meaning of Torque Motor?

The meaning of torque motor can be understood by splitting the idea into two parts. Torque is the twisting force that causes rotation. Motor is a machine that converts electrical power into mechanical motion. So the meaning of torque motor is a motor built to produce twisting force in a controlled and reliable way, especially for applications where smooth low-speed movement, stable holding, and accurate positioning matter more than fast spinning.

In cinematic electronics, this meaning becomes very practical. It refers to a motor that helps move or hold cameras, lenses, and rigs with precision, smoothness, and low noise so that the final shot looks stable and professional.

What is the Future of Torque Motor?

The future of torque motors looks strong because modern machines increasingly demand direct drive precision, quiet performance, and smarter control. In cinema and media production, trends like virtual production, robotic cinematography, drone filming, and high-resolution imaging raise the standards for motion smoothness and repeatability.

Smarter motor control: Motor drives are improving with better algorithms for smoother torque, reduced ripple, and better disturbance rejection. This will help stabilize shots even more effectively and will improve the natural feel of robotic moves.

Higher torque density materials: Advances in magnet materials, winding methods, and cooling techniques can increase torque without increasing size. This will allow lighter gimbals, smaller robotic heads, and more compact camera rigs.

More integration in cinematic systems: Frameless torque motors will be integrated directly into camera heads, robotic joints, and modular cinema rigs. This reduces weight and makes equipment easier to balance and transport.

Improved sensor feedback: Encoders are becoming higher resolution and more robust. Better feedback improves repeatability, especially for VFX workflows and multi-camera synchronization.

Energy efficiency and thermal management: Future torque motors will likely use improved thermal paths, better insulation, and more efficient drives. This supports long shoots with stable performance and fewer interruptions.

Safety and collaborative robotics: As robotic camera systems work closer to people, torque-controlled motors can provide safer interaction through precise force limiting and smooth response. This will expand the use of robotics in tighter sets and live production environments.

Broader creative possibilities: With more precise and accessible torque motor systems, filmmakers will be able to create complex camera moves reliably, repeat them easily, and combine them with real-time engines and virtual sets.

Summary

- A torque motor is designed to deliver high torque at low speed, including stable holding torque at zero speed.

- It works through controlled electromagnetic interaction between stator windings and a rotor, usually with feedback sensors and a motor controller.

- Key components include stator windings, rotor magnets, precision air gap, bearings, housing for thermal management, feedback sensors, and a motor drive.

- Common types include direct drive torque motors, frameless torque motors, brushless and brushed torque motors, servo torque motors, and hollow shaft designs.

- Applications include robotics, precision stages, aerospace stabilization, medical devices, industrial automation, and many cinema motion systems.

- In cinema, torque motors enable smooth gimbal stabilization, precise pan tilt control, repeatable motion control, and quiet robotic camera movement.

- Main objectives include smooth torque output, accurate repeatability, fast response, reduced mechanical complexity, and low noise performance.

- Benefits include minimal backlash, high motion smoothness, strong holding ability, lower maintenance, better VFX repeatability, and reduced vibration.

- Features often include high torque density, low-speed stability, torque mode control, encoder compatibility, hollow shaft options, and reduced cogging designs.

- The future includes smarter control, higher torque density, better thermal design, improved feedback sensors, safer robotics, and deeper integration into cinematic electronics.