What is Linear Motor?

A linear motor is an electric motor that produces motion in a straight line instead of rotation. In a traditional motor, the rotor spins inside the stator and that rotation is later converted into linear movement using mechanical parts like belts, gears, screws, or cams. A linear motor removes much of that conversion stage by creating thrust directly along a track. Think of it as an electric motor that has been unrolled and laid flat so the force is created forward and backward, not around a shaft.

In the world of cinematic electronics, linear motors matter because cinema equipment often needs smooth, silent, repeatable movement. Cameras glide, focus systems shift lens elements, lighting rigs slide into position, and stage mechanisms move props precisely. When the movement is direct and controlled, the results look more professional on screen, and the crew can repeat the same motion for multiple takes with the same timing and distance.

Linear motors are commonly used where precision and speed are important and where low mechanical complexity improves reliability. Because there is no need for gearboxes or lead screws in many setups, the motion can be extremely responsive. This makes linear motors a strong match for high-end motion control systems used in film production, virtual production stages, and advanced camera robotics.

How does Linear Motor Work?

A linear motor works by using electromagnetic forces to create thrust along a straight path. The core principle is the same as many rotating motors: magnetic fields interact to produce motion. The difference is in geometry. Instead of magnetic forces producing torque around a center, they generate a push or pull along a line.

Primary section: The moving or powered part contains windings that receive electrical current. When current flows through these windings, it creates a magnetic field that changes in a controlled sequence.

Secondary section: The stationary track, or sometimes the moving track, provides a magnetic reaction surface. Depending on the design, the secondary can contain permanent magnets or conductive material that responds to the changing magnetic field.

Electromagnetic interaction: By energizing the windings in a timed pattern, the motor creates a traveling magnetic field. This traveling field pulls or pushes against the secondary, producing linear thrust. The direction and speed depend on how the controller sequences the current.

Control and feedback: To achieve cinematic smoothness, the system typically uses sensors such as encoders or linear scales to measure position and speed. A motor drive then adjusts current in real time to maintain the desired motion profile. This is how the motor can start gently, accelerate smoothly, hold a constant speed, and stop without jerks.

One of the reasons linear motors feel so precise is that they can reduce backlash. Backlash is the small delay or play that happens in mechanical transmissions like gears or belts. In cinema motion control, even tiny inconsistencies can show up as stutter, micro-vibrations, or uneven framing. Direct-drive linear motion helps reduce those issues, especially when combined with high-quality feedback systems and well-tuned control loops.

What are the Components of Linear Motor?

A linear motor system is more than just magnets and coils. In cinema applications, it is usually part of a complete motion axis with structure, control electronics, sensing, and safety features.

Stator or primary windings: These are coils of copper arranged to produce a controlled magnetic field when energized. In many designs, the primary is the active part connected to the motor drive.

Magnet track or secondary: This is the reaction surface. In permanent magnet linear motors, this section uses arrays of magnets that create a strong magnetic field. In induction-style linear motors, the secondary may be a conductive plate or rail.

Motor drive or amplifier: This converts power into controlled current waveforms for the windings. It is responsible for commanding thrust and shaping acceleration and deceleration for smooth movement.

Motion controller: This is the brain that plans motion profiles and coordinates multiple axes. In cinematic rigs, it may synchronize camera movement with focus, zoom, lighting cues, or LED wall playback.

Feedback sensors: Encoders, linear scales, Hall sensors, or other position sensing devices tell the controller exactly where the carriage is. High-resolution feedback is essential for repeatable takes.

Carriage or forcer assembly: The moving part that carries the load, such as a camera plate, lens module, light head, or stage element. It mounts to the linear motor and runs along guides.

Linear guides and bearings: Even though the thrust is produced electromagnetically, the system still needs mechanical guidance. Precision rails, bearings, or air bearings keep motion straight and stable.

Cable management system: Moving axes need careful routing of power and signal cables. Cable chains help prevent snagging and reduce vibration caused by cable drag.

Power supply and braking system: Some systems include regenerative braking or resistors to handle energy during deceleration. Safety brakes may be used to prevent uncontrolled motion if power is lost.

Thermal management: Linear motors can generate heat, especially at high thrust. Heat sinks, airflow paths, and temperature sensors help maintain performance and protect components.

Safety features: Limit switches, soft limits in software, emergency stop circuits, and overload detection are critical for film sets where people work close to moving machinery.

What are the Types of Linear Motor?

Linear motors come in several types, each with different performance characteristics. The best choice depends on speed, thrust, precision, environment, and budget.

Linear induction motor: This type works similarly to an induction motor. The primary creates a traveling magnetic field that induces currents in the secondary. These currents create a reaction field that produces thrust. It is robust and can work over long distances, but it often has lower efficiency and lower precision than permanent magnet designs.

Permanent magnet synchronous linear motor: This type uses permanent magnets on the secondary and energized windings on the primary. It provides high force density, excellent responsiveness, and high precision. It is widely used in high-end automation and can be adapted well for cinema robotics and motion control.

Iron-core linear motor: The primary contains iron laminations that concentrate magnetic flux, increasing thrust. This provides strong force output, but cogging effects can appear, which may require careful design and control tuning to maintain smoothness.

Ironless or coreless linear motor: The primary has no iron core. This reduces cogging and can produce very smooth motion, which is valuable for camera movement. The trade-off is usually lower peak thrust compared to iron-core designs and higher sensitivity to external magnetic influences.

Tubular linear motor: This design is cylindrical rather than flat. It looks like a rod and sleeve that move relative to each other. Tubular linear motors can be compact and clean, making them useful for actuating lens elements, shutters, or compact motion devices.

Voice coil actuator: A voice coil is a form of linear motor optimized for short strokes and very smooth, fast response. It is common in focus mechanisms, stabilization systems, and precision positioning tasks where travel distance is limited.

Long-stator vs short-stator configurations: In long-stator setups, the primary windings extend along the track and the moving part may be magnet-based. In short-stator setups, the moving forcer contains the windings and travels along a magnet track. Each approach affects cable management, cost, and scalability.

What are the Applications of Linear Motor?

Linear motors are used anywhere direct, controlled linear motion is needed. In cinematic electronics, their applications can be divided into production, post-production hardware, and supporting stage infrastructure.

Camera motion control systems: Linear motors can drive sliders, dollies, and robotic camera rails with high precision. They enable repeatable moves for visual effects shots, product cinematography, and time-lapse work.

Robotic arms and gantries: Many modern camera robots use linear axes as part of a multi-axis system. A linear motor axis can provide fast repositioning and smooth tracking shots, especially in studio setups.

Focus, zoom, and iris actuation: Compact linear actuators such as voice coils or tubular linear motors can move lens elements accurately. This is useful for autofocus modules, lens calibration rigs, and special cine lens systems that integrate electronic control.

Stabilization and vibration control: Some stabilization systems use linear actuators to counter motion. While many gimbals use rotating motors, linear actuation can appear in certain balancing or damping mechanisms, especially in specialized rigs.

LED volume and virtual production stage mechanisms: On large stages, components like movable walls, tracking markers, or mechanical mounts may require precise linear adjustment. Linear motors can support fast and repeatable stage reconfiguration.

Automated lighting rigs: Linear actuators can adjust light position, beam shaping elements, or moving diffusers. Smooth motion matters because any jerk can create visible shifts in reflections or shadows during a take.

Set automation and prop movement: Linear motors can move panels, doors, practical effects components, and props with controlled speed profiles that look natural on camera.

Precision alignment systems: Camera calibration rigs, lens testing benches, and sensor alignment platforms can use linear motors to position equipment with micrometer-level repeatability.

Sound-stage equipment where noise matters: Linear motors can be quieter than some geared mechanisms when designed well, which is helpful for dialogue-heavy scenes where mechanical noise can ruin audio.

What is the Role of Linear Motor in Cinema Industry?

In cinema, technology is not only about making things move. It is about making movement look intentional, smooth, and repeatable. Linear motors support this by delivering controlled motion directly along the path that the audience sees.

Smooth camera movement: Many cinematic shots rely on motion that feels floating and stable. Linear motors can produce consistent velocity and clean acceleration curves, helping avoid sudden jolts that look amateurish.

Repeatability for multiple takes: Visual effects workflows often require repeating the same camera move across multiple passes. For example, you may film a clean plate, then a pass with actors, then practical effects elements. A linear motor driven system with precise feedback can repeat the move accurately, simplifying compositing.

Precision for macro and product shots: In close-up cinematography, even tiny motion errors are magnified. Linear motors provide fine positioning to achieve subtle pushes, pulls, and reveals while maintaining stable framing.

Support for motion control storytelling: Directors and cinematographers use motion to convey emotion. A slow creep forward builds tension. A sudden lateral move reveals information. With linear motor control, these movements can be crafted with exact timing.

Integration with modern cinematic electronics: Motion systems today are integrated with software, tracking, and synchronization. A linear motor axis can be coordinated with focus pulling, LED wall playback, and real-time rendering. This coordination is key in virtual production environments.

Reduced mechanical complexity on set: A motor that provides direct drive can reduce reliance on gear trains and belts, which can reduce maintenance and improve reliability. On a busy set, reliability and quick setup can save valuable time.

Safety and controlled automation: Film sets include people, cables, and expensive gear. A well-designed linear motor system with proper limits and emergency stops can move heavy rigs predictably, reducing risk compared to improvised mechanical setups.

Enabling new creative tools: Advanced camera robots, programmable sliders, and intelligent rigs are becoming more accessible. Linear motors help power these tools, making high-end motion language available to more productions.

What are the Objectives of Linear Motor?

The objectives of using a linear motor, especially in cinematic electronics, are tied to performance, control, and creative outcomes.

Direct linear motion: The first objective is to produce thrust along a straight line without needing mechanical conversion from rotation.

High precision positioning: Linear motors aim to achieve accurate placement and repeatable travel, supporting complex choreography and multiple-take consistency.

Smooth motion profiles: Another objective is to create fluid acceleration and deceleration that look natural on camera and do not introduce vibration.

High dynamic response: Linear motors are designed to react quickly to control commands, enabling fast repositioning and precise tracking of moving subjects.

Reduced mechanical wear: By reducing the number of mechanical transmission parts, linear motors aim to lower wear, reduce maintenance, and improve long-term stability.

Improved synchronization: In multi-axis cinema rigs, one objective is to synchronize movement across axes and other devices such as focus motors, lighting changes, or stage cues.

Quiet operation potential: While not always silent, many linear motor systems are designed to minimize audible noise, supporting clean dialogue recording.

Compact and modular design: Another objective is to create motion modules that can be integrated into sliders, dollies, robots, and lens systems without excessive bulk.

Energy efficiency and thermal control: Systems aim to deliver required thrust without excessive heat buildup, keeping performance stable over long takes.

Safety and predictability: A critical objective is predictable behavior, with controlled stops and safe handling of faults, especially on set.

What are the Benefits of Linear Motor?

Linear motors provide practical and creative benefits that are especially valuable in film production and cinematic electronics.

Direct drive accuracy: Because thrust is produced directly, there is less backlash and fewer mechanical uncertainties. This improves framing consistency and move repeatability.

Excellent smoothness: With proper design and tuning, linear motors can create very smooth motion, which is ideal for cinematic camera moves.

Fast acceleration and high speed: Many linear motors can accelerate quickly and reach high speeds. This is useful for dynamic shots and rapid repositioning between takes.

High repeatability: Motion control work benefits from being able to repeat a move precisely. Linear motors with encoders can deliver repeatable results.

Lower mechanical complexity: Removing belts, gears, and screws can simplify the mechanical design. Fewer parts can mean fewer failures and less maintenance.

Better control of micro-movements: Subtle, slow motion is often the hardest to do cleanly. Linear motor control can deliver stable low-speed motion when tuned correctly.

Integration with advanced control systems: Linear motors work well with digital motion controllers, enabling synchronized moves, keyframed motion, and programmable profiles.

Potentially quieter operation: When compared with some geared systems, linear motors can reduce mechanical noise. This benefit depends on the full system design, including guides and mounts.

Long stroke scalability: Certain linear motor designs can be built for long travel distances, supporting large studio camera rails and gantry systems.

Improved creative freedom: When movement is reliable and repeatable, crews can attempt more complex shots with confidence.

What are the Features of Linear Motor?

Linear motors have technical features that explain why they perform well in precision motion tasks.

Linear thrust generation: Force is generated directly along the travel path, reducing dependence on mechanical conversion systems.

High-resolution feedback compatibility: Linear motors often pair with encoders and scales, supporting precise position and velocity control.

Programmable motion profiles: Motion can be shaped through software, including gentle ramps, S-curve profiles, and custom timing for cinematic effect.

Low backlash potential: Direct drive reduces backlash, improving stability and predictability during starts, stops, and direction changes.

High force density options: Permanent magnet designs can produce strong thrust in a compact form, which is useful for heavy camera payloads.

Modular track-based construction: Many linear motor systems are built as modular tracks, making it easier to extend travel length.

Multiple design forms: Flat, tubular, iron-core, ironless, and voice coil designs allow engineers to match the motor to the application.

Regenerative braking capability: Some drives can recover energy during deceleration, improving efficiency and reducing heat in braking resistors.

Smooth low-speed control: With good control tuning, linear motors can maintain stable slow motion, which is essential for subtle camera moves.

Advanced safety integration: Many systems support limit switches, software limits, torque or thrust limiting, and emergency stop integration.

What are the Examples of Linear Motor?

Linear motors appear in both specialized cinematic tools and in supporting technologies that influence cinema production environments.

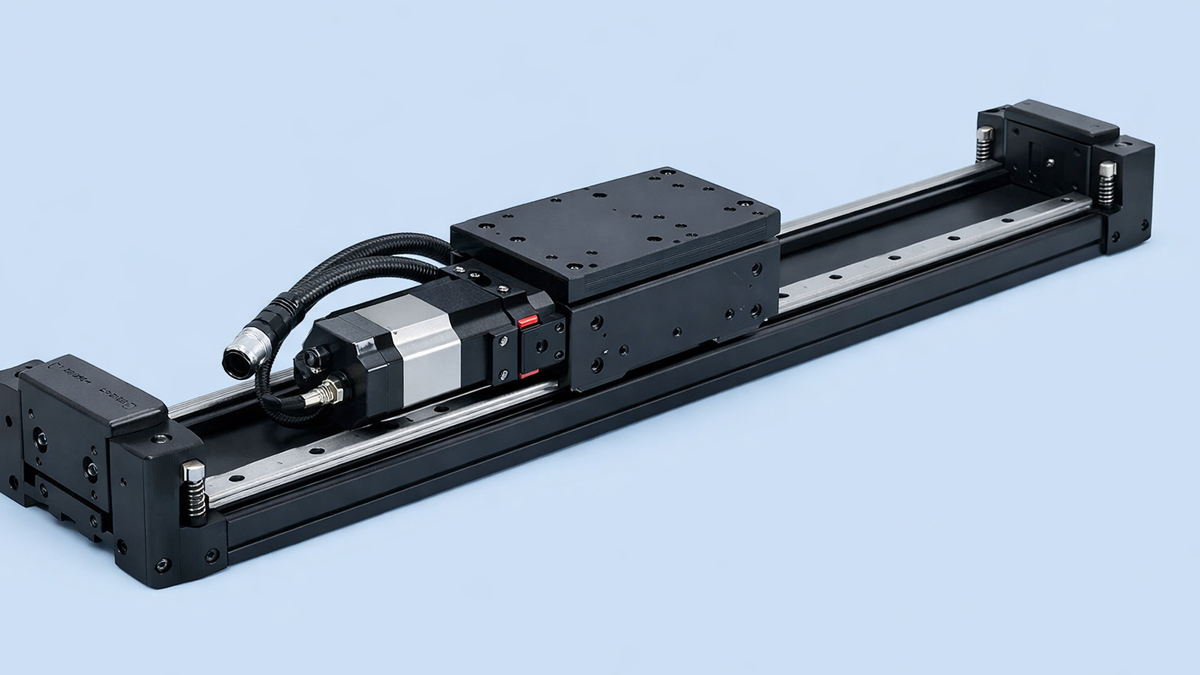

Camera slider with direct drive axis: A studio-grade motion control slider can use a permanent magnet linear motor to move the camera carriage smoothly and repeatably.

Motion control dolly track: A larger system used for VFX plates and repeatable moves can use a long linear motor track to drive a dolly platform.

Gantry camera system: Overhead rigs in studios can combine multiple linear axes to position a camera anywhere within a rectangular space.

Lens element actuator: A tubular linear motor or voice coil actuator can move focusing elements quickly and precisely in an electronically controlled lens module.

Precision calibration stage: Equipment used to calibrate cameras, lenses, or sensors may use ironless linear motors for smooth micro-positioning.

Set automation rail: A prop movement mechanism can use a linear motor to slide a panel or door with controlled timing that matches the action.

Virtual production adjustment axis: Stage equipment that needs accurate alignment may use linear actuators to fine-tune positions without introducing mechanical play.

Haptic or vibration module: Certain cinema gear prototypes may use voice coil actuators to generate controlled vibration for testing stabilization or simulating motion cues.

What is the Definition of Linear Motor?

A linear motor is an electric motor that converts electrical energy into linear mechanical motion by generating electromagnetic thrust along a straight path. It is essentially a motor designed to produce movement directly in a line rather than producing rotational torque.

In engineering terms, it performs the same energy conversion as a rotary motor but with a linear geometry. This direct linear output makes it valuable in systems where precise straight-line movement is required, especially when smoothness and repeatability are important.

What is the Meaning of Linear Motor?

The meaning of linear motor can be understood by breaking down the concept into purpose and behavior. It is a motor built to move something along a straight line with electrical control. Instead of turning a shaft, it pushes or pulls a moving part along a rail, track, or tube.

In practical terms, the meaning includes the idea of direct drive linear motion, programmable control, and the ability to achieve smooth movement without relying heavily on gears or belts. In cinema industry workflows, it means controlled motion that can be repeated precisely for storytelling and technical production needs.

What is the Future of Linear Motor?

The future of linear motors in cinematic electronics is closely linked to trends in automation, virtual production, robotics, and audience expectations for higher-quality visuals.

More intelligent motion control: Motion systems are becoming smarter, with software that assists operators in designing moves, avoiding collisions, and repeating sequences automatically. Linear motors will benefit from improved control algorithms, better tuning tools, and smoother real-time feedback.

Growth of virtual production: LED volume stages and real-time rendering require tight coordination between camera movement and the virtual scene. Linear motor axes will increasingly be used in camera tracking rigs, repeatable moves, and robotic systems that integrate with tracking data.

Higher precision with simpler rigs: As costs reduce and manufacturing improves, linear motor based systems may become more common even in smaller productions. This can bring high-end smoothness and repeatability to independent filmmaking.

Compact linear actuation inside lenses and accessories: As lenses and camera accessories become more electronically integrated, compact linear motors such as voice coils and tubular actuators may play a bigger role in focus systems, stabilization modules, and adaptive optics mechanisms.

Improved energy efficiency and thermal performance: Future designs may reduce heat through better materials, optimized magnet arrays, more efficient drives, and improved regenerative braking. This is important for long shooting days where equipment must remain stable.

Better noise control: Sound-sensitive productions will continue to push for quieter motion gear. This may lead to refined bearing systems, improved structural damping, and control strategies that reduce audible artifacts.

Increased safety and collaboration on set: Collaborative robotics is expanding in many industries. In cinema, safer motion systems that can work near crew and actors will grow, using sensors, force limits, and predictive control. Linear motors, with their precise controllability, can support these safety goals.

More modular production ecosystems: Film equipment is moving toward modular, reusable platforms. Linear motor axes can become building blocks that plug into different rigs, from sliders to dollies to stage automation, with standardized control interfaces.

Summary

- A linear motor is an electric motor that produces straight-line motion instead of rotation.

- It works by creating a traveling magnetic field that generates thrust along a track or tube.

- Key components include windings, a magnetic or conductive secondary, drive electronics, sensors, guides, and safety systems.

- Major types include induction, permanent magnet synchronous, iron-core, ironless, tubular, and voice coil designs.

- Applications include camera sliders, motion control rails, robotic systems, lens actuation, lighting automation, and set mechanisms.

- In the cinema industry, linear motors support smooth shots, repeatable takes, precise movement, and better synchronization with modern production tools.

- Objectives focus on direct drive motion, precision, smoothness, fast response, reduced wear, reliability, and safe automation.

- Benefits include low backlash potential, high repeatability, strong control of micro-movements, reduced mechanical complexity, and creative flexibility.

- Features include programmable motion profiles, high feedback compatibility, scalable track design, and advanced safety integration.

- The future points toward smarter motion control, deeper virtual production integration, quieter systems, and more accessible high-precision tools for filmmakers.