What is Ultra Fast Recovery Diode?

An ultra fast recovery diode is a type of power diode designed to switch from conducting to blocking extremely quickly. In simple words, it is built to stop current flow in a very short time after the voltage polarity changes. This matters because many modern electronic circuits do not run on slow, smooth sine waves only. They use high frequency switching that turns current on and off thousands to millions of times per second. In such circuits, a normal rectifier diode can be too slow to stop conducting, which creates losses, unwanted heat, and electrical noise.

The main specialty of an ultra fast recovery diode is its very low reverse recovery time. Reverse recovery time is the time the diode takes to remove stored charge inside its junction when it changes from forward biased to reverse biased. If that stored charge is removed slowly, the diode keeps conducting briefly in reverse direction. That reverse current spike can stress nearby components, reduce efficiency, and generate interference. Ultra fast recovery diodes are engineered to reduce that time dramatically compared to standard rectifier diodes.

In cinematic electronics under the cinema industry, where reliability, stable power delivery, and low noise are essential, ultra fast recovery diodes are often used in power supplies and conversion circuits. They help projectors, LED walls, audio amplifiers, camera systems, motion control rigs, and server racks run efficiently with less heat and fewer switching artifacts. The result is equipment that performs consistently during long screenings, continuous shooting schedules, and demanding live events.

How does Ultra Fast Recovery Diode Work?

An ultra fast recovery diode works like a one way valve for current, but with an optimized internal structure that clears stored charge quickly when switching. When the diode is forward biased, current flows through it with a certain forward voltage drop. During this conduction, charge carriers build up in the junction region. When the circuit quickly reverses polarity, the diode should stop conducting. However, those stored charge carriers need to be removed first. That removal process is the reverse recovery.

Reverse recovery behavior: When the diode switches from forward conduction to reverse blocking, there is a brief period where reverse current flows. This happens because the diode is still clearing its stored charge. In ultra fast recovery diodes, the design reduces how much charge is stored and helps sweep it out faster, so the reverse current spike is smaller and shorter.

Carrier lifetime control: Manufacturers often use techniques such as lifetime control to reduce how long charge carriers remain in the device. This helps the diode recover faster. The tradeoff is that forward voltage drop and leakage characteristics must be balanced carefully for power performance.

Soft recovery vs abrupt recovery: Some ultra fast recovery diodes are designed with soft recovery behavior. This means the reverse current decays smoothly instead of abruptly snapping off. Smooth decay reduces electromagnetic interference and ringing in the circuit. This can be very valuable in cinema systems where audio noise and video artifacts must be minimized.

Switching in real circuits: In a switching power supply, a transistor turns on and off rapidly. When it turns off, the current path shifts, often through a diode. If that diode has slow recovery, it fights the switching action and causes extra loss and heat. An ultra fast recovery diode supports the rapid switching by turning off quickly, reducing wasted power and protecting the switching transistor from current spikes.

What are the Components of Ultra Fast Recovery Diode?

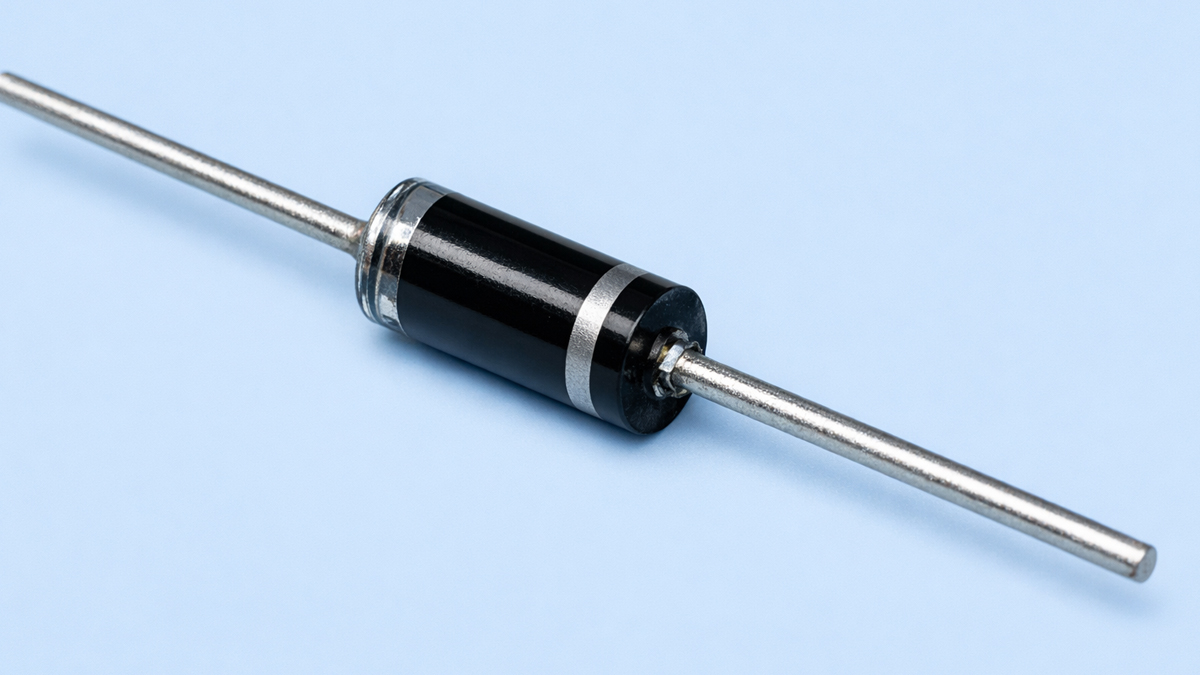

An ultra fast recovery diode is a semiconductor device, so its key components are internal layers and external packaging elements rather than mechanical parts. Still, it is useful to break down what makes it work.

Semiconductor junction: The heart of the diode is the PN junction or a variation of it, such as a PIN structure in many power diodes. The junction is where conduction occurs in forward bias and blocking occurs in reverse bias.

Drift region: Many power diodes include a drift region that supports high reverse voltage. The thickness and doping of this region influence voltage rating, switching speed, and conduction loss.

Lifetime control region: In ultra fast recovery diodes, the device may include engineered regions or controlled impurities to reduce minority carrier lifetime. This is one of the reasons recovery time becomes ultra fast.

Metallization and contacts: Metal layers form the anode and cathode connections. These contacts must handle high current with low resistance, and they must be thermally stable.

Passivation layer: Protective layers on the semiconductor surface prevent contamination and stabilize performance over time, especially under high voltage stress.

Package body: Common packages include axial lead packages, through hole power packages, and surface mount packages. The package determines how heat is removed and how easily the diode can be mounted in cinema equipment power boards.

Lead frame or terminals: These connect the diode to the circuit. In higher power versions, the terminals are designed to carry large current and help move heat to a heatsink or copper plane.

Thermal path: Even though it is not a separate part you can see, the thermal design is critical. Heat must travel from the junction to the package and into the board or heatsink. Better thermal paths improve reliability in projectors and audio amplifiers that run hot.

What are the Types of Ultra Fast Recovery Diode?

Ultra fast recovery diodes come in several types, mainly based on structure, recovery behavior, and application voltage and current ranges.

Standard ultra fast recovery diode: This is the general purpose ultra fast diode with very low reverse recovery time, commonly used in switching power supplies, inverters, and motor drives.

Soft recovery ultra fast diode: This type is tuned so that reverse recovery current decays smoothly. It reduces ringing and electromagnetic interference, which helps protect sensitive audio and video electronics in cinema systems.

High voltage ultra fast recovery diode: Designed for higher reverse voltage ratings, these are useful in high power conversion stages, such as projector lamp drivers or high voltage power supplies in older xenon based systems and some specialized cinema equipment.

High current ultra fast recovery diode: Built for larger forward current handling. These appear in power distribution modules, amplifier rails, and LED wall power supplies.

Ultrafast rectifier modules: Some applications use diode modules containing multiple ultra fast diodes configured as bridges or dual diodes. These simplify assembly and improve thermal handling in high power racks.

Fast recovery vs ultra fast recovery distinction: Fast recovery diodes are quicker than standard rectifiers but slower than ultra fast recovery diodes. Ultra fast devices typically target much shorter recovery times and better performance at higher switching frequencies.

Comparison to Schottky diodes: Schottky diodes are very fast because they have little to no reverse recovery charge, but they can have lower voltage ratings and higher leakage at high temperature. Ultra fast recovery diodes fill the gap where higher voltage capability and strong ruggedness are needed with very fast switching.

What are the Applications of Ultra Fast Recovery Diode?

Ultra fast recovery diodes are used wherever high frequency switching, efficiency, and reduced noise are important. In cinematic electronics, many systems depend on switch mode power conversion, so these diodes are common.

Switch mode power supplies: Projectors, LED processors, cinema servers, audio amplifiers, and control panels often use switch mode power supplies. Ultra fast recovery diodes improve efficiency and reduce heat generation.

Power factor correction circuits: Many large cinema power supplies include power factor correction stages. Ultra fast diodes support the high frequency switching used in these circuits.

Inverters and converters: LED walls and stage lighting often use DC to DC converters and inverters. Ultra fast recovery diodes help reduce switching loss and improve stability.

Motor drives and motion systems: Camera cranes, sliders, gimbals, and moving stage elements rely on motor drives. Ultra fast recovery diodes can be used in freewheeling paths and snubber networks to protect switches and control energy flow.

Snubber and clamp circuits: Ultra fast recovery diodes are used with resistors and capacitors to clamp voltage spikes and reduce ringing. This protects transistors and improves electromagnetic compatibility.

Audio amplifier power rails: High power cinema audio amplifiers need clean, stable DC rails. Ultra fast recovery diodes can reduce switching noise in associated power supply sections and help maintain reliability.

Battery chargers and UPS systems: Cinemas and production studios use backup power systems. Ultra fast diodes improve performance in charging circuits and power conversion stages.

High frequency rectification in specialized gear: Some camera systems, wireless transmitters, and monitoring equipment have compact high frequency converters where fast diodes are required.

What is the Role of Ultra Fast Recovery Diode in Cinema Industry?

Ultra fast recovery diodes play a supporting but critical role in keeping cinema technology reliable, efficient, and clean in terms of electrical noise. The cinema industry depends on systems that must run for hours without failure, maintain consistent brightness and sound quality, and avoid interference that can show up as audible hum, visual artifacts, or control glitches.

Power stability in digital cinema projectors: Modern projectors rely on sophisticated power electronics for light sources, imaging chips, fans, and control systems. Ultra fast recovery diodes contribute to efficient conversion and reduced thermal stress, helping projectors maintain stable operation through long screenings.

Noise control for audio systems: Cinema sound systems amplify small signals into powerful outputs. Electrical noise from power electronics can leak into audio paths if not controlled. By reducing reverse recovery spikes and ringing in power circuits, ultra fast recovery diodes can help lower the chance of interference and unwanted noise.

Reliable operation for LED cinema walls: Some theaters use LED direct view displays instead of projection. LED walls require multiple high power supplies and converters. Ultra fast recovery diodes improve efficiency and reduce heat, which helps prevent power supply failures and brightness inconsistencies.

Support for cinema servers and networking racks: Playback servers, storage systems, routers, and processors run continuously. Their power supplies must be efficient and robust. Ultra fast recovery diodes help reduce losses and stress on switching components, improving uptime.

On set cinematic electronics: Film production uses mobile power solutions, battery systems, and compact converters for cameras, monitors, wireless systems, and lighting. Ultra fast recovery diodes help these devices remain efficient and compact, extending battery runtime and reducing heat.

Reduced maintenance and downtime: In cinema venues, downtime is expensive. Components that run cooler and experience less switching stress typically last longer. Ultra fast recovery diodes contribute to this by lowering switching losses and reducing voltage and current spikes.

Electromagnetic compatibility in complex environments: A cinema or production set can include many electronic systems packed close together. Reduced switching noise helps different systems coexist without interference, protecting sensitive control lines and communication links.

What are the Objectives of Ultra Fast Recovery Diode?

The objectives of using an ultra fast recovery diode are practical engineering goals focused on speed, efficiency, reliability, and noise control.

Fast switching support: Ensure the diode can transition from conduction to blocking quickly in high frequency switching circuits.

Reduce reverse recovery losses: Minimize energy wasted during the reverse recovery period, improving overall efficiency.

Protect switching devices: Reduce reverse recovery current spikes that can stress MOSFETs, IGBTs, and other switching transistors.

Lower heat generation: Reduce power loss to keep the diode and nearby components cooler, improving lifespan.

Reduce electromagnetic interference: Limit abrupt current changes and ringing that create electrical noise affecting audio and video systems.

Improve power density: Enable smaller power supplies by supporting higher switching frequencies with manageable losses.

Enhance reliability: Provide stable operation under repetitive switching conditions in demanding cinema and studio environments.

Maintain signal integrity: Help keep sensitive electronics free from power related noise that could affect processing, playback, and control.

What are the Benefits of Ultra Fast Recovery Diode?

Ultra fast recovery diodes offer benefits that directly impact the performance and durability of cinema equipment.

Higher efficiency: Faster recovery reduces switching losses, which means more input power becomes useful output power.

Lower operating temperature: Less wasted energy becomes heat. Cooler operation improves component reliability and reduces thermal stress on boards.

Improved durability of power switches: Reduced reverse current spikes protect transistors and reduce the risk of failure in power stages.

Cleaner electrical environment: Lower ringing and reduced interference support quieter audio and more stable video processing.

Better performance at high frequency: These diodes allow power supplies to run at higher switching frequencies, which can reduce the size of transformers and inductors.

Better system uptime: In theaters and studios, fewer failures and less overheating means fewer interruptions and less maintenance.

Better energy management in mobile rigs: On set equipment benefits from efficient power conversion that extends battery life and keeps gear cooler.

Stronger suitability for high voltage tasks: Compared to many Schottky options, ultra fast recovery diodes often handle higher reverse voltages with strong ruggedness.

What are the Features of Ultra Fast Recovery Diode?

Ultra fast recovery diodes are identified by a set of electrical and practical features. These features help engineers pick the right diode for cinema related systems.

Low reverse recovery time: A key feature is very short recovery time, which supports high frequency switching.

Low reverse recovery charge: Lower stored charge reduces the size and duration of reverse recovery current spikes.

High reverse voltage rating options: Many ultra fast diodes are available in ratings that suit high power conversion circuits.

High surge current capability: Power diodes often handle brief surge currents, useful during startup and transient conditions.

Optimized soft recovery versions: Some are designed specifically to reduce electromagnetic interference by shaping the recovery waveform.

High temperature operation capability: Many are designed to perform reliably at elevated junction temperatures typical in projector power supplies and amplifier racks.

Robust packaging: Power packages with strong thermal performance support continuous operation.

Predictable switching behavior: Consistent recovery performance helps designers reduce variability, which improves reliability across many installed systems.

Compatibility with snubber networks: Ultra fast recovery diodes work well alongside snubbers and clamps to manage transients.

What are the Examples of Ultra Fast Recovery Diode?

Examples can be explained in two ways: real world use cases in cinema systems and typical device families used in power electronics.

Cinema projector power supply rectification: Ultra fast recovery diodes are used in rectification and freewheeling paths inside switch mode supplies that power digital projectors.

LED wall power modules: Many LED panels and processors rely on DC to DC converters that use ultra fast recovery diodes in output rectification or clamp circuits.

Cinema audio amplifier SMPS: High power amplifiers often use switch mode supplies. Ultra fast recovery diodes can be used in secondary rectification stages, snubber networks, or auxiliary rails.

Camera battery powered converters: Portable converters that step voltage up or down may use ultra fast recovery diodes where higher voltage ratings are required.

UPS and backup power units for theaters: Ultra fast recovery diodes can appear in charging circuits and inverter related stages, helping improve efficiency and manage switching stress.

General device category examples: Common families include ultrafast rectifier diodes designed for power supplies, soft recovery ultrafast diodes designed for low noise operation, and dual diode modules used for higher current rectification.

Selection example context: A designer might choose a soft recovery ultra fast diode for an audio sensitive power supply, while choosing a higher current ultra fast diode for a projector power stage where load is heavy.

What is the Definition of Ultra Fast Recovery Diode?

An ultra fast recovery diode is a power semiconductor diode designed to switch from forward conduction to reverse blocking with a very short reverse recovery time, minimizing stored charge effects and reducing switching losses in high frequency power circuits.

What is the Meaning of Ultra Fast Recovery Diode?

The meaning of ultra fast recovery diode can be understood by breaking down the term in simple language.

Ultra fast: The diode can stop conducting and return to a blocking state very quickly when the circuit changes direction.

Recovery: Recovery refers to the process of removing stored charge in the diode junction after it has been conducting.

Diode: A diode is a device that allows current to flow mainly in one direction and blocks it in the opposite direction.

So the overall meaning is a diode that returns to its blocking state extremely quickly after being switched, making it suitable for modern high speed power electronics used throughout cinema and production technology.

What is the Future of Ultra Fast Recovery Diode?

The future of ultra fast recovery diodes will be shaped by how cinema technology evolves and how power electronics continues to improve. While new semiconductor devices are gaining popularity, ultra fast recovery diodes remain important because they are cost effective, rugged, and widely available.

Higher efficiency cinema systems: Cinemas are focusing more on energy efficiency. Projectors, LED walls, and audio racks will continue to demand efficient power conversion. Ultra fast recovery diodes will keep improving to reduce losses further and support higher switching frequencies.

Growth of LED cinema and large format displays: As LED direct view cinema expands, the number of high power supplies in venues may increase. That creates more demand for reliable and low noise rectification and protection components. Ultra fast recovery diodes, especially soft recovery types, will remain useful in these power architectures.

Better electromagnetic compatibility requirements: Venues and studios have more wireless devices, more networking, and more sensitive digital processing. Power electronics must be quieter electrically. Manufacturers will likely keep refining recovery waveforms to reduce interference, making soft recovery ultra fast diodes more common.

Competition and coexistence with new technologies: Silicon carbide diodes and other advanced devices offer very low recovery losses and high voltage performance, often with superior switching behavior. However, they can be more expensive. The future will likely involve a mix, where silicon carbide is used in premium high power stages, and ultra fast recovery silicon diodes remain in many cost sensitive or mid power systems.

Smaller and denser power supplies: Higher switching frequency enables smaller magnetics and more compact power units. Ultra fast recovery diodes will continue to be optimized for low charge and low loss so designers can push power density without overheating.

Improved thermal packaging: Packaging improvements such as better thermal pads, lower resistance connections, and enhanced heat spreading will increase reliability. This matters in cinema environments where equipment runs continuously and replacement costs can be high.

Smarter power modules: More systems are moving toward integrated power modules that include diodes, switches, and control in compact forms. Ultra fast recovery diode structures may be integrated into such modules more often, simplifying assembly and boosting robustness.

Long life reliability focus: Cinemas want stable operation for many years. Ultra fast recovery diodes will continue to be optimized for reliability under repetitive switching, temperature cycling, and surge conditions.

Summary

- Ultra fast recovery diodes are power diodes designed to stop conducting quickly when polarity changes.

- Their key advantage is very short reverse recovery time, which reduces switching losses and heat.

- They help protect switching transistors by reducing reverse current spikes and electrical stress.

- Soft recovery versions reduce ringing and electromagnetic interference, supporting clean audio and stable video.

- They are widely used in switch mode power supplies, inverters, snubbers, and power factor correction circuits.

- In the cinema industry they support projectors, LED walls, audio amplifiers, servers, and on set power systems.

- Benefits include higher efficiency, cooler operation, better reliability, and reduced maintenance downtime.

- The future includes ongoing improvements in low noise recovery behavior and thermal packaging, alongside coexistence with newer diode technologies.