What is Toroidal Inductor?

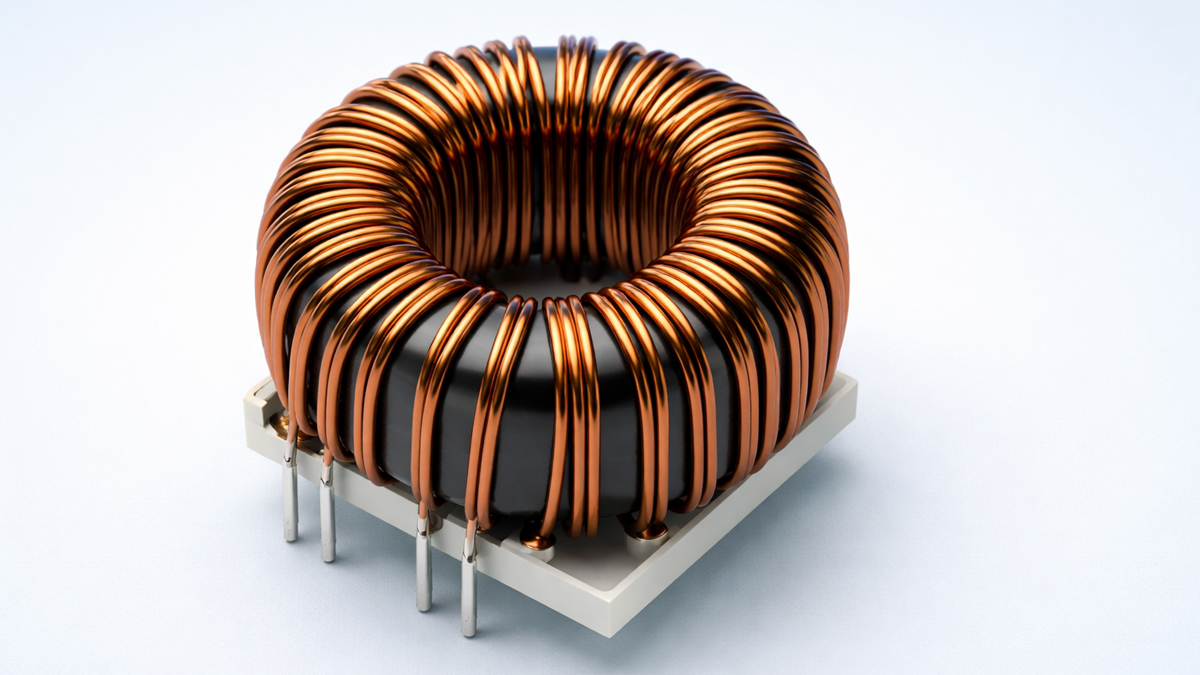

A toroidal inductor is a type of inductor that is built by winding insulated wire around a donut-shaped magnetic core, called a toroid. In simple terms, it is a component used to store energy in a magnetic field and to control how electrical current changes over time. What makes a toroidal inductor special is the shape of its core. Because the core is circular and closed, most of the magnetic field stays inside the core instead of spreading into the surrounding air. This gives the toroidal inductor a clean and efficient magnetic path.

In cinematic electronics under the cinema industry, toroidal inductors are often used because they help reduce electrical noise and electromagnetic interference. Cinema equipment depends on stable power, clean audio, reliable digital processing, and accurate signal transmission. When electronics are operating in the same space as sensitive microphones, audio mixers, wireless receivers, camera control systems, lighting dimmers, projectors, and networked playback systems, noise control becomes extremely important. Toroidal inductors support this need because they naturally contain their magnetic field better than many other inductor shapes.

Purpose and core idea: A toroidal inductor is designed to provide inductance with high efficiency, strong magnetic coupling, and reduced stray fields.

Where it fits in cinematic electronics: It is commonly found in power supplies, audio filtering, EMI suppression circuits, and high-current energy storage stages that keep cinema systems stable and quiet.

How does Toroidal Inductor Work?

A toroidal inductor works based on electromagnetic induction. When current flows through the coil of wire wound around the toroidal core, it creates a magnetic field. The toroidal core provides a path that guides this magnetic field in a closed loop. As the current increases, the magnetic field strengthens. As the current decreases, the magnetic field weakens. This change in magnetic field induces a voltage that opposes the change in current. This is why inductors resist sudden changes in current.

Magnetic field containment: Because the toroid is a closed ring, the field is mostly confined inside the core. This reduces stray magnetic radiation into nearby circuits. In cinema environments, this can help protect audio preamps, analog stages, and sensitive RF systems from hum and unwanted coupling.

Energy storage behavior: Inductors store energy when current flows, and they release energy when the circuit demands it. In cinema power systems, especially in switch-mode power supplies, energy storage and controlled release are essential for steady voltage rails that feed processors, amplifiers, and projection systems.

Filtering action: Toroidal inductors are often used as chokes or filter inductors. They block high-frequency noise while allowing lower-frequency power or signals to pass. In cinematic electronics, this matters because switching regulators, LED drivers, motor controllers, and network devices can inject high-frequency noise into power lines.

Saturation and limits: The core material determines how much magnetic flux it can handle before saturating. When saturation occurs, the inductance drops and performance degrades. Designers choose core materials and sizes based on current level, frequency, and required inductance to keep the inductor operating safely in cinema-grade equipment.

What are the Components of Toroidal Inductor?

A toroidal inductor may look simple, but it is made of carefully chosen parts that define its performance. Each component is selected based on required inductance, current rating, heat handling, and noise behavior.

Core material: The toroidal core is the most important part. Common materials include ferrite, powdered iron, and other specialty magnetic composites. Ferrite is widely used for high-frequency applications such as EMI suppression and switch-mode power supplies. Powdered iron is often used for energy storage inductors because it can handle DC bias better and saturates more gradually.

Core shape and size: The donut shape is constant, but the diameter and thickness vary. A larger core generally allows higher inductance, higher current handling, and lower temperature rise, but it also increases size and cost. In cinema equipment racks where airflow and space are planned carefully, size selection is a practical engineering decision.

Winding wire: Copper wire is most common because of its excellent conductivity. The wire can be solid or stranded. For higher frequencies, designers may use special wire types to reduce skin effect losses, such as litz wire. In high-current cinema power stages, thicker wire is used to reduce resistance and heat.

Insulation and coating: The wire is insulated with enamel or other coatings to prevent short circuits. Additional insulation layers may be used to meet safety and reliability requirements, especially in power supplies connected to mains voltage.

Leads and termination: Toroidal inductors need electrical connections to the circuit board or wiring harness. Leads can be standard wire leads, solderable pins, or sometimes flat terminals for higher current.

Mounting and mechanical support: Toroids can be mounted using adhesive, clamps, brackets, or through-hole mounting kits. Vibration resistance and mechanical stability matter in cinema environments where equipment may be transported, installed in racks, or used in mobile production setups.

Protective wrapping or casing: Some toroidal inductors have tape wrapping, heat shrink, or molded coverings for protection, insulation, and long-term durability.

What are the Types of Toroidal Inductor?

Toroidal inductors can be categorized in several ways. In cinematic electronics, the type chosen depends on frequency, current, size, and noise constraints.

Power toroidal inductors: These are designed to handle higher currents and store energy in power conversion circuits. They are common in switch-mode power supplies, DC to DC converters, and power conditioning units used in cinema racks.

Toroidal chokes: These are used mainly for filtering and noise suppression. They can block unwanted high-frequency noise on power lines or signal lines. In cinema systems, they help reduce interference that could affect audio quality and data integrity.

Common-mode toroidal chokes: These are special chokes with two windings that suppress common-mode noise. They are used in EMI filters on AC mains inputs and on data lines. Cinema equipment often needs common-mode chokes to meet electromagnetic compliance requirements and to avoid interference between tightly packed devices.

Differential-mode toroidal inductors: These are used to filter noise that appears between two conductors. They support cleaner power delivery and smoother operation of switching circuits.

Ferrite toroidal inductors: These use ferrite cores and are optimized for high-frequency applications and EMI suppression. They are widely used in filtering stages.

Powdered iron toroidal inductors: These use powdered iron cores and are typically used for energy storage, especially in power converters. They handle DC bias better and are useful where stable inductance under load is important.

High-frequency toroidal inductors: These are designed with materials and winding techniques that reduce losses at higher switching frequencies. Modern cinema equipment often uses high-frequency power conversion to improve efficiency and reduce size.

High-current toroidal inductors: These are optimized for low resistance, better cooling, and strong current capacity. Audio amplifiers, power distribution modules, and projector power systems can benefit from this category.

What are the Applications of Toroidal Inductor?

Toroidal inductors are used across many electronic systems, and they are especially valuable where efficiency and low noise are required. In cinematic electronics, the focus is often on clean power and interference control.

Power supply filtering: Toroidal inductors are used in input and output filters of power supplies. They smooth ripple, reduce switching noise, and stabilize voltage rails.

Switch-mode power supplies: Many cinema devices use switch-mode power supplies because they are efficient and compact. Toroidal inductors store energy and control current flow in these converters.

Audio amplifier power stages: Audio amplifiers require stable, clean power. Toroidal inductors help filter noise and reduce hum that could reach speakers in a cinema hall.

EMI and RFI suppression: Cinemas contain many electronic sources of interference, including lighting controllers, network switches, wireless systems, and high-power projectors. Toroidal chokes help reduce EMI and RFI on cables and power lines.

Signal conditioning and filtering: In some analog and mixed-signal circuits, inductors help create filter networks. While capacitors and active filters are common, inductors remain useful in certain designs where passive filtering is preferred.

Motor and actuator control circuits: Some cinema-related systems include moving parts, such as motorized screens, curtain systems, seating actuators, ventilation control, and camera rigs in production. Toroidal inductors support filtering and current control in motor driver electronics.

LED lighting drivers: Cinematic lighting and architectural lighting in theaters often use LED drivers that switch at high frequency. Toroidal inductors are frequently used in these driver circuits.

Networking and data equipment: Cinema playback servers, digital cinema processors, and network distribution gear need stable power and compliance with EMI standards. Toroidal inductors and chokes support cleaner operation.

What is the Role of Toroidal Inductor in Cinema Industry?

In the cinema industry, electronics must deliver two things at the same time: high performance and high reliability. A toroidal inductor supports both by helping power and signal systems remain stable, quiet, and efficient.

Noise reduction for clean audio: Cinema audio chains are sensitive. Even small interference can become noticeable as hum, buzz, or hiss across large speaker systems. Toroidal inductors help filter switching noise from power supplies and reduce magnetic coupling into audio circuits. This supports clear dialogue, stronger dynamic range, and a cleaner listening experience.

Stable power for projectors and servers: Digital cinema projectors and media servers need stable voltage rails. Ripple and spikes can cause errors, glitches, or long-term stress on components. Toroidal inductors in power conditioning and internal converters help smooth and regulate power, supporting consistent operation during long show schedules.

Electromagnetic compatibility in dense equipment racks: Cinema booths and projection rooms often pack many devices close together. EMI from one unit can affect another, especially when cables are bundled and power distribution is shared. Toroidal common-mode chokes and filter inductors reduce conducted and radiated noise, helping systems coexist without interference.

Efficiency and thermal control: Power losses become heat. Heat shortens component life and can lead to shutdowns. Toroidal inductors typically offer good efficiency and controlled magnetic fields, helping reduce unnecessary losses. This supports cooler equipment racks and more stable long-term performance.

Reliability in continuous operation: Cinemas run for many hours daily. Components that run cool, avoid saturation, and reduce stress on circuits contribute to fewer failures. Toroidal inductors are often selected in robust designs for their predictable behavior and stable magnetic path.

Support for modern switching architectures: Many cinema electronics use advanced switch-mode conversion, power factor correction, and filtering stages. Toroidal inductors are a practical fit because they can be designed for specific frequency ranges and current profiles while keeping noise manageable.

What are the Benefits of Toroidal Inductor?

Toroidal inductors bring a set of benefits that make them widely used in cinema-grade electronics. These benefits are practical and measurable in real systems.

Lower electromagnetic interference: The toroidal shape contains the magnetic field inside the core, reducing stray radiation. This helps keep audio and signal circuits cleaner.

Higher efficiency: With a closed magnetic path and strong coupling, toroidal inductors often have lower losses than many alternative shapes, especially in well-designed power circuits.

Compact design for given performance: Toroids can provide high inductance in a relatively compact form because the magnetic path is efficient.

Improved filtering performance: Toroidal chokes and filter inductors can offer effective suppression of high-frequency noise, supporting stable power rails and quieter operation.

Reduced hum in audio systems: By limiting stray fields and improving power filtering, toroidal inductors help reduce audible hum and buzz in cinema sound systems.

Better current handling options: Toroidal inductors can be designed with thick windings and suitable core materials to handle significant current, supporting amplifiers, projectors, and power distribution systems.

Good thermal behavior when properly designed: Efficient operation means less heat. With appropriate mounting and airflow, toroidal inductors can operate reliably for long durations.

What are the Features of Toroidal Inductor?

Features describe the practical characteristics that engineers look for when selecting a toroidal inductor for cinematic electronics.

Closed-loop magnetic path: The core shape guides magnetic flux in a loop, which improves coupling and reduces stray fields.

Wide range of core materials: Toroids can be made from ferrite, powdered iron, and other composites, allowing optimization for frequency, saturation behavior, and losses.

Flexible inductance values: Inductance can be adjusted by changing turns count, core size, and material properties. This allows designs to match exact power and filtering requirements.

Low leakage flux: Compared to many other core shapes, toroidal inductors generally have lower leakage, which reduces interference and improves performance in dense electronic environments.

High Q potential in certain designs: With suitable materials and winding techniques, toroidal inductors can achieve good quality factor, supporting efficient filtering.

Mechanical robustness options: Toroids can be wrapped, taped, or mounted securely, supporting long-term reliability in racks and installations.

Custom winding configurations: Designers can implement single winding, multiple windings, tapped windings, or paired windings for common-mode choking, expanding their usefulness in cinema electronics.

What are the Examples of Toroidal Inductor?

Examples help connect the idea of a toroidal inductor to real cinema-related equipment and circuit blocks. These examples focus on where you might realistically find toroidal inductors in cinematic electronics.

Power input EMI filter choke in a digital cinema projector: A toroidal common-mode choke at the AC input helps reduce conducted noise and improves electromagnetic compliance.

Output filter inductor in a projector power supply: A toroidal inductor smooths current and reduces ripple feeding sensitive internal electronics.

DC to DC converter in a cinema media server: Toroidal inductors support energy storage and stable voltage conversion for processors, storage drives, and networking hardware.

Audio amplifier switching power supply filter: In high-power cinema amplifiers, toroidal inductors are used to reduce switching noise and keep the audio output clean.

LED driver filter inductor for theater lighting: Architectural and stage lighting drivers may include toroidal inductors that reduce ripple and electromagnetic noise.

Noise suppression choke on long cable runs: Some cinema installations use toroidal chokes on power or signal cables to reduce interference from nearby equipment.

What is the Definition of Toroidal Inductor?

A toroidal inductor is an inductor made by winding a conductor around a torus-shaped magnetic core, designed to store energy in a magnetic field and oppose changes in current, while keeping most of its magnetic flux contained within the core.

In cinematic electronics, this definition matters because controlled magnetic behavior and low interference are critical to maintaining clean power and signals across cinema systems.

What is the Meaning of Toroidal Inductor?

The meaning of toroidal inductor becomes clearer when you break down the words.

Toroidal meaning: Toroidal refers to the shape of a torus, which looks like a ring or donut. This shape provides a closed path for magnetic flux.

Inductor meaning: An inductor is a passive electronic component that stores energy in a magnetic field when current flows through it and resists changes in current.

Combined meaning in simple terms: A toroidal inductor is a ring-shaped inductor that is designed to be efficient and quiet by keeping magnetic fields mostly inside its core.

Meaning in cinema industry context: It is a component that helps cinema electronics stay stable, reduce noise, and maintain reliable performance during continuous operation.

What is the Future of Toroidal Inductor?

The future of toroidal inductors in cinematic electronics will be shaped by evolving cinema technology, power efficiency demands, and stricter requirements for electromagnetic cleanliness.

Growth of high-efficiency power systems: Cinema equipment continues to move toward efficient power conversion, smaller power supplies, and better thermal management. Toroidal inductors will remain important because they support efficient switching converters and filtering networks.

Higher switching frequencies and advanced materials: As power electronics move to higher frequencies and adopt newer semiconductor technologies, inductors must reduce losses and handle faster switching edges. Toroidal designs will benefit from improved ferrites, optimized powdered iron mixes, and advanced core materials that reduce heat and improve stability.

Improved EMI compliance and quieter electronics: Modern cinemas rely on dense networks, digital audio transport, and wireless coordination. These systems can be sensitive to interference. Toroidal chokes and filter inductors will remain essential to controlling conducted noise and meeting compliance standards.

More integration and better manufacturing methods: Manufacturing improvements can deliver toroidal inductors with tighter tolerances, better winding consistency, and stronger mechanical reliability. Automated winding and improved insulation methods can support higher production quality.

Customization for cinema-grade modules: Cinema integrators often need reliable performance across varied conditions. The future may include more custom toroidal inductors designed for specific power modules, amplifier platforms, and projector subsystems.

Sustainability and energy management: Cinemas increasingly look for energy efficiency and reduced maintenance. Toroidal inductors that improve power factor correction stages, reduce losses, and support stable power distribution can contribute to greener operations.

Continued role in hybrid analog and digital chains: Even as cinema becomes more digital, analog front ends still exist in audio capture, monitoring, amplification, and certain control circuits. Toroidal inductors will continue to support noise management across these mixed environments.

Summary

- Toroidal inductors are ring-shaped inductors that store energy in a magnetic field and resist changes in current.

- Their closed-loop core contains magnetic flux, which helps reduce electromagnetic interference in cinema electronics.

- They are widely used in power supplies, EMI filters, audio amplifier power stages, LED drivers, and high-current converters.

- Core materials like ferrite and powdered iron determine frequency behavior, losses, and saturation performance.

- Toroidal chokes and common-mode chokes are especially valuable for reducing conducted noise in cinema equipment racks.

- In the cinema industry, they support cleaner audio, stable projector and server power, improved reliability, and better compliance.

- The future of toroidal inductors includes improved materials, higher-frequency optimization, better manufacturing consistency, and stronger EMI control needs.