What is Power Inductor?

A power inductor is an electronic component designed to store energy in a magnetic field and release that energy when the circuit needs it. In simple words, it is like a small energy buffer that helps power flow smoothly inside electronic equipment. Power inductors are built to handle higher currents than small signal inductors, which is why they are used in power supplies, voltage regulators, motor drivers, and many other circuits that move and control real electrical power.

In cinematic electronics under the cinema industry, power inductors quietly support many systems that people rely on every day. They help projectors maintain stable light output, keep audio amplifiers clean and powerful, protect delicate digital boards from noisy power, and support battery powered gear used on film sets. Whether it is a cinema projector, a digital cinema server, a professional audio rack, a camera monitor, a wireless transmitter, or LED lighting, power conversion is everywhere. Power inductors are a key part of that conversion.

Core purpose: Store energy and smooth current flow so that electronic systems get steady, reliable power even when the load changes quickly.

Why it matters in cinema: Cinema equipment often has sudden changes in power demand, such as bright scenes in projection, bass hits in audio, motor movement, or wireless transmission bursts. A power inductor helps manage these changes without instability, overheating, or distortion.

How does Power Inductor Work?

A power inductor works by opposing sudden changes in current. When current flows through its coil, it creates a magnetic field. Energy is stored in that field. When the circuit conditions change, the magnetic field can collapse and push energy back into the circuit. This behavior allows the inductor to reduce ripple, filter noise, and support stable voltage conversion.

Energy storage principle: Current flowing through the coil creates a magnetic field. The stronger the current, the stronger the magnetic field, and the more energy is stored.

Current smoothing: If the current tries to rise too quickly, the inductor resists that change. If the current tries to drop too quickly, the inductor releases stored energy to slow the drop. This makes current flow more continuous and less jumpy.

Switching power supplies connection: In modern electronics, most power conversion is done using switching regulators. A switching regulator rapidly turns a transistor on and off. The inductor stores energy during the on time and releases it during the off time. By controlling the switching pattern, the regulator creates a stable output voltage. This is how many cinema devices convert power efficiently with less heat.

Noise control: Inductors also help reduce high frequency noise by blocking fast changing current components. That is valuable in cinema electronics because noise can appear as hum in audio, interference in wireless systems, or instability in digital processing boards.

Cinema reliability angle: Power inductors help cinema systems run for long hours in warm rooms, enclosed racks, and high duty cycles. Stable power reduces crashes, reduces distortion, and extends equipment life.

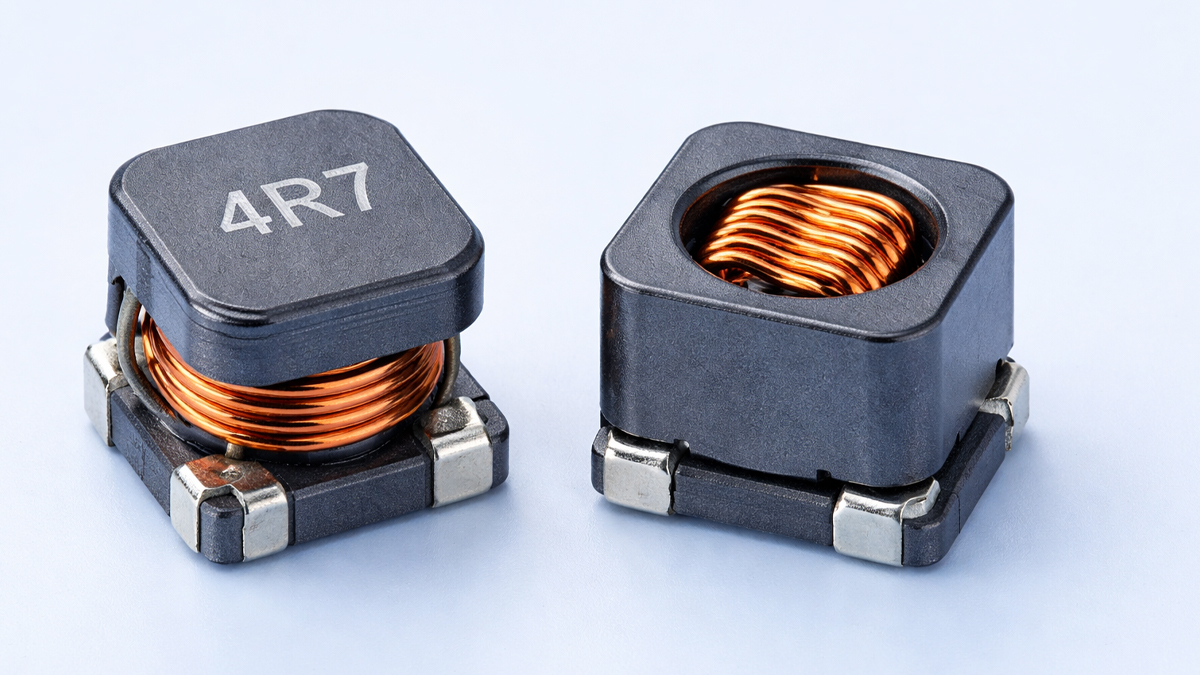

What are the Components of Power Inductor?

A power inductor may look simple from the outside, but it is built from several important elements that determine performance, safety, and lifespan.

Coil winding: The winding is the conductor, usually copper wire or copper foil, wrapped in turns. More turns generally increase inductance, but also increase resistance and size. The winding method affects heat handling and efficiency.

Core material: Many power inductors use a magnetic core to increase inductance and energy storage capability. Common cores include ferrite, powdered iron, and composite materials. The core choice strongly affects saturation current, losses, and noise.

Air gap concept: Some inductors include a physical or distributed air gap. The gap helps store more energy and increases saturation resistance. Many power inductors for switching regulators rely on a gapped core design.

Bobbin or former: Some inductors use a bobbin to hold the coil shape. Others are molded or shielded designs without a visible bobbin.

Insulation and coating: Insulation prevents short circuits between turns and protects the winding from moisture and vibration. Coatings can include enamel on wire, varnish, epoxy, or molded compounds.

Shielding structure: Shielded power inductors have a magnetic shield that reduces stray magnetic fields. This is especially useful near sensitive circuits like audio preamps, RF modules, and image processing boards.

Terminations and leads: Inductors need strong electrical and mechanical connections. Through hole inductors use leads. Surface mount inductors use pads designed for automated assembly and reliable solder joints.

Thermal path: Power inductors generate heat due to resistance and core losses. Better designs provide a path for heat to flow into the circuit board and into the surrounding air or chassis.

Quality focus in cinema equipment: Strong insulation, stable core materials, and good thermal design are critical because cinema systems may run continuously for many hours, often in warm projection booths or crowded equipment racks.

What are the Types of Power Inductor?

Power inductors come in several types. The right choice depends on current level, switching frequency, noise sensitivity, physical space, and cost.

Shielded power inductors: These have a magnetic shield that reduces electromagnetic interference. They are common in audio equipment, wireless systems, and digital cinema boards where noise control is important.

Unshielded power inductors: These are often cheaper and can handle high current, but they radiate more magnetic field. They can be suitable when placed away from sensitive circuits.

Ferrite core power inductors: Ferrite cores work well at higher frequencies and have low core losses. They are widely used in switching power supplies in projectors, servers, and monitor power rails.

Powdered iron core inductors: Powdered iron has distributed air gaps, allowing higher energy storage and good saturation characteristics. They can be used in some converters but may have higher losses at very high frequencies.

Composite molded inductors: These use a mixture of magnetic powder and resin molded around the coil. They can be robust, handle vibration well, and provide good shielding in compact packages.

Toroidal inductors: The core is shaped like a ring. Toroids can have low stray fields and good efficiency. They are common in higher power supplies and audio power stages.

Drum core inductors: A common shape in compact designs. Some are partially shielded or unshielded. They are widely used on DC to DC converter boards.

Planar inductors: These are built using flat copper traces and special core structures. They are useful in very high current applications and can be integrated into compact power modules.

Cinema relevance note: Shielded and low noise designs are often preferred near audio paths and RF modules, while high current rugged inductors are needed in projection lamp supplies, motor drivers, and large power conversion stages.

What are the Applications of Power Inductor?

Power inductors are used wherever power needs to be converted, filtered, or stabilized. In cinema related electronics, you will see them in many layers of the system.

DC to DC converters: Converting one DC voltage to another, such as 48V to 12V, 12V to 5V, or 5V to 1.0V for processors. This is common in cinema servers, media players, control boards, and networking equipment.

AC to DC power supplies: After rectification, inductors help filter and smooth current, improving efficiency and lowering ripple.

Audio amplifiers: Class D amplifiers use inductors in output filters to reconstruct clean audio from high frequency switching signals. Many modern cinema amplifiers use Class D for efficiency and reduced heat.

EMI and ripple filtering: Inductors are used with capacitors to form filters that reduce noise and ripple on power rails, protecting sensitive audio and video circuits.

Motor drivers and actuators: Cinema seating systems, projector mechanisms, lens movement systems, and some automation devices use power electronics with inductors to control motors.

Battery powered equipment: On film sets, cameras, monitors, wireless transmitters, recorders, and LED lights often rely on battery packs. Inductors are key parts of efficient regulators that extend battery life.

LED lighting drivers: LED panels and stage lighting use switching drivers to control brightness with stability. Inductors help regulate current and reduce flicker.

Wireless and RF equipment power rails: Stable, low noise power is essential for wireless microphones, in ear monitors, intercom systems, and video transmitters. Inductors support clean conversion and filtering.

What is the Role of Power Inductor in Cinema Industry?

The cinema industry depends on a chain of electronic systems that must work reliably under demanding conditions. Power inductors contribute by keeping power stable, efficient, and clean across devices that create picture, sound, control, and connectivity.

Projection systems stability: Digital cinema projectors include high power sections, multiple regulated rails, cooling systems, image processing boards, and control logic. Power inductors help provide stable DC rails so brightness, color processing, and timing remain consistent.

Audio quality protection: Cinema sound must be powerful, clean, and free from hum. Power inductors support amplifier power supplies and Class D output filters. They help reduce ripple and switching noise that could leak into audio paths.

Digital cinema servers and media playback: Servers include CPUs, GPUs, storage drives, and network interfaces. These subsystems draw rapidly changing current. Power inductors in voltage regulator modules help keep processor rails stable, preventing glitches and crashes.

Signal integrity for image processing: Video processing boards require stable rails for clocks, memory, and interfaces. Noise on power lines can cause timing errors, image artifacts, or intermittent faults. Inductors in filtering stages reduce these risks.

Lighting and stage control on sets: Film and production environments use LED lighting, dimmers, and control modules. Inductors help deliver steady current and reduce flicker, which is vital for camera capture.

Portability and efficiency: Many cinema tools must be portable and battery powered. Efficient conversion saves battery power and reduces heat. Power inductors are central to that efficiency.

Thermal and continuous operation: Cinema equipment often runs for long durations. Efficient power conversion reduces heat stress, helping components last longer and operate more safely.

Interference management: Cinemas have complex environments with audio, RF microphones, networking, and digital electronics all in proximity. Shielded power inductors and good filtering reduce electromagnetic interference that could affect performance.

What are the Objectives of Power Inductor?

A power inductor is chosen and designed to meet specific objectives in a power circuit. In cinema electronics, these objectives often focus on stability, quality, efficiency, and reliability.

Voltage regulation support: Provide energy storage needed for buck, boost, and buck boost converters so the output voltage stays stable even when the load changes quickly.

Ripple reduction: Reduce current ripple and voltage ripple on power rails, which improves audio clarity, video stability, and system reliability.

Noise filtering: Block high frequency noise and reduce electromagnetic interference that can affect audio, wireless communication, and digital signal integrity.

Energy transfer: Store and release energy during switching cycles to move power efficiently from input to output.

Current continuity: Maintain smoother current flow to reduce stress on capacitors, switches, and loads.

Protection and robustness: Help limit current spikes and reduce sudden stress during power on events or fast load changes.

Thermal efficiency: Support efficient conversion so less power is wasted as heat, which is important in enclosed racks and projector housings.

Compact system design: Enable smaller and more efficient power supply designs so cinema equipment can be compact and portable when needed.

What are the Benefits of Power Inductor?

Power inductors deliver practical benefits that can be felt as better performance, better reliability, and lower operating costs.

Improved power stability: Stable power rails reduce unexpected shutdowns, glitches, and performance drops in cinema servers, projectors, and control systems.

Better audio performance: Cleaner power and proper Class D filtering reduce noise, hiss, and hum, allowing clearer dialogue and tighter bass.

Reduced heat generation: Efficient conversion reduces heat in equipment racks and projector housings, which can improve overall lifespan and reduce cooling requirements.

Higher efficiency for portable gear: Battery powered equipment benefits from efficient DC to DC conversion, giving longer runtime and more consistent performance.

Lower electromagnetic interference: Shielded inductors and good filtering reduce interference, helping wireless microphones, intercoms, and video links remain stable.

System durability: Smoother current and reduced stress can extend the life of capacitors, switching transistors, and connectors.

Improved flicker control in lighting: Stable current regulation in LED drivers helps reduce flicker and supports consistent lighting for camera capture.

Scalable power design: Power inductors enable designs that range from small handheld devices to high power cinema equipment.

What are the Features of Power Inductor?

A power inductor is often selected based on key features that define how it behaves in real systems. These features matter a lot in cinematic electronics where both performance and reliability are important.

Inductance value: Measured in microhenry or millihenry. The inductance value affects ripple, transient response, and converter stability.

Saturation current rating: The maximum current the inductor can handle before the core saturates and inductance drops significantly. This is critical in high load cinema systems.

RMS current rating: The current level the inductor can handle thermally without overheating, based on copper losses and core losses.

Low DC resistance: Lower resistance reduces power loss and heat. This improves efficiency, especially in battery powered gear and high power supplies.

Core loss characteristics: Core materials differ in losses at different frequencies. Proper selection improves efficiency in switching regulators.

Shielding performance: Shielded inductors reduce stray magnetic fields and help prevent interference with nearby circuits.

Size and footprint: Cinema designs often balance performance with space constraints, especially in compact cameras, monitors, and wireless devices.

Temperature rating: Inductors must perform reliably across expected temperature ranges. Projection booths and lighting gear can run warm.

Mechanical robustness: Vibration resistance and strong solder joints matter in portable gear, touring cinema rigs, and on set equipment.

Acoustic noise control: Some inductors can produce audible coil noise under certain conditions. Better designs reduce this risk, which is important in quiet recording environments and high fidelity audio systems.

What are the Examples of Power Inductor?

Power inductors show up in many real cinema and production devices. Here are clear examples of where you will commonly find them.

Cinema projector power modules: Inductors inside switch mode power supplies provide regulated rails for control electronics, imaging boards, and cooling systems.

Digital cinema server and media player boards: Voltage regulator modules near CPUs, GPUs, and memory include power inductors for stable low voltage rails.

Cinema audio amplifiers: Class D amplifiers use output filter inductors. Power supplies inside amplifiers also use inductors for conversion and filtering.

Rack mounted processors and crossovers: Digital signal processing units require multiple regulated voltages with low noise filtering, supported by inductors.

LED cinema lighting fixtures: Constant current drivers use inductors as part of buck or boost converter stages to regulate LED current and dimming.

Camera monitors and field recorders: Portable units use inductors in DC to DC converters to create stable rails from battery packs.

Wireless microphone receivers and transmitters: RF performance improves when power rails are clean, and inductors help convert and filter power efficiently.

On set battery distribution systems: DC distribution boxes and power management modules use inductors in their regulator stages.

Motorized camera rigs and focus systems: Motor drivers and control electronics include inductors in power stages to handle dynamic loads.

Networking and control equipment: Switches and controllers inside cinema environments include power inductors in their power supplies for stable operation.

What is the Definition of Power Inductor?

A power inductor is a passive electronic component designed to store energy in a magnetic field, manage current changes, and support efficient power conversion and filtering in circuits that carry moderate to high current.

Key emphasis: Power inductors are built for power handling, thermal performance, and stable behavior in switching power systems.

What is the Meaning of Power Inductor?

The meaning of power inductor can be understood by focusing on its job in real devices. It is a component that makes power usable. Electricity coming from a battery, adapter, or power supply is not always in the right form for every circuit. Different parts of cinema equipment need different voltages and currents, and they need them to be stable and clean.

Practical meaning: A power inductor helps convert electrical power efficiently and keeps power smooth so electronic systems can operate without noise, distortion, or instability.

Cinema meaning: It helps ensure that picture stays consistent, sound stays clean, and equipment stays reliable during long shows and demanding production work.

What is the Future of Power Inductor?

The future of power inductors is closely tied to trends in power electronics, digital cinema technology, and production equipment design. As cinema systems demand more performance in smaller spaces, the inductor must evolve in efficiency, size, and noise control.

Higher power density: Devices are becoming smaller but more powerful. This pushes inductors toward compact designs with better thermal paths and higher current capability.

Improved magnetic materials: New ferrites and composite materials are being developed to reduce losses at higher switching frequencies. Lower losses mean less heat and better efficiency.

Higher switching frequencies: Many regulators are moving to higher frequencies to reduce the size of inductors and capacitors. This requires cores that perform well without excessive loss.

Better shielding and lower EMI: With more wireless devices and sensitive digital processing in cinema systems, inductors with improved shielding will be increasingly important.

Integration into power modules: Some systems integrate inductors into complete power modules, simplifying design and improving reliability. This can help cinema manufacturers build more compact and serviceable products.

Focus on acoustic quietness: As audio and recording environments demand low noise, inductor designs that reduce coil noise and vibration will become more valuable.

Sustainability and efficiency: Energy efficiency is a growing priority for cinemas and production houses. More efficient power conversion reduces electricity costs and cooling needs, supporting sustainability goals.

Reliability improvements: Expect more inductors designed for long life, high temperature operation, and stable performance under continuous load, which aligns with cinema operation requirements.

Summary

- Power inductors store energy in a magnetic field and help keep current smooth and stable in power circuits.

- They are essential in switching regulators that convert voltages efficiently in cinema projectors, servers, audio systems, and lighting.

- Key internal parts include the winding, core material, insulation, shielding structure, and terminations.

- Common types include shielded, unshielded, ferrite core, powdered iron, molded composite, toroidal, drum core, and planar inductors.

- Cinema applications include DC to DC conversion, ripple filtering, Class D amplifier filtering, LED drivers, portable battery systems, and motor control.

- Their cinema industry role is to support stable picture, clean sound, reliable digital processing, efficient portable gear, and reduced interference.

- Main objectives include voltage regulation support, noise reduction, energy transfer, current continuity, protection from spikes, and thermal efficiency.

- Benefits include improved reliability, better audio clarity, lower heat, higher efficiency, less EMI, longer component life, and steadier lighting.

- Important features include inductance value, saturation current, RMS current, DC resistance, core loss behavior, size, temperature rating, and robustness.

- The future points toward smaller and more efficient inductors with better materials, better shielding, module integration, and improved low noise performance.