What is Chip On Board LED?

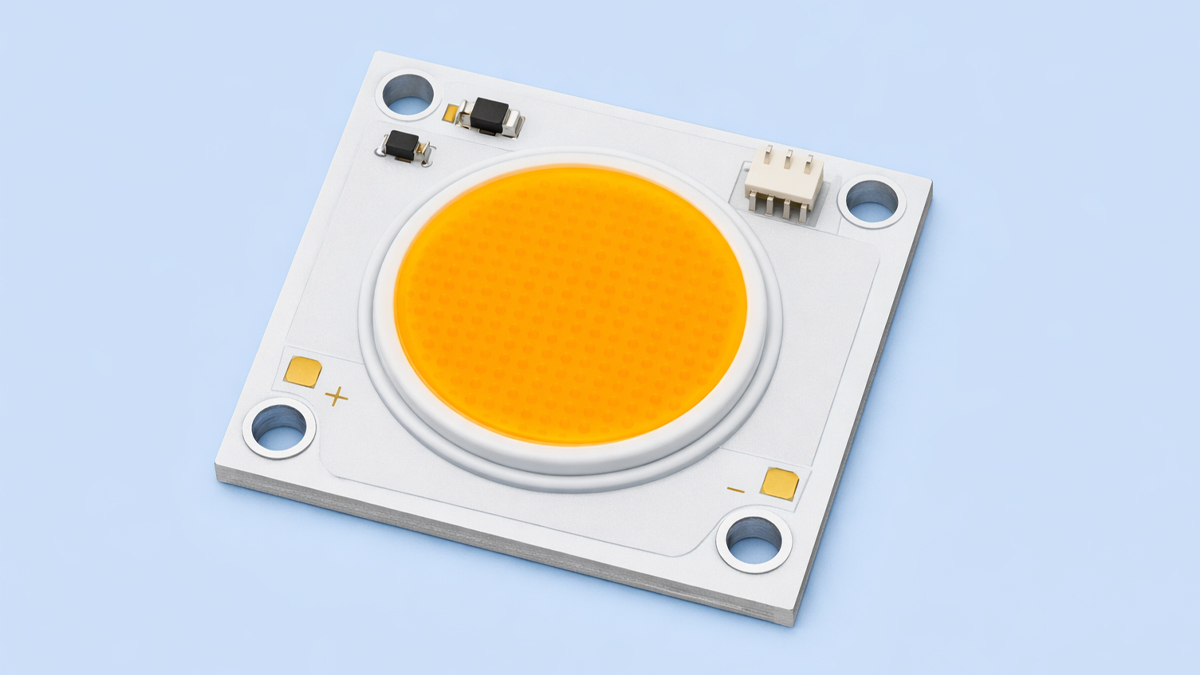

Chip On Board LED is an advanced lighting technology in which multiple LED chips are mounted directly onto a single substrate to form one lighting module. Instead of packaging each LED chip individually, this method places many tiny semiconductor chips close together on a circuit board and then covers them with a layer of phosphor coating. The result is a powerful, uniform light source that appears as a single bright panel rather than multiple individual light points.

In the context of cinematic electronics under the cinema industry, Chip On Board LED plays a vital role in creating high quality lighting systems. These systems are used in film production, studio lighting, theater stages, projection environments, and cinema halls. Because cinema demands precise color accuracy, consistent brightness, and controlled illumination, Chip On Board LED has become a preferred solution for lighting designers and technicians.

Traditional LED lighting systems used Surface Mounted Device technology, where each diode is packaged separately. Chip On Board LED improves this concept by increasing chip density, reducing size, and enhancing luminous efficiency. The compact design allows higher brightness from a smaller surface area. This is especially important in film production, where space, heat management, and lighting uniformity are critical factors.

Chip On Board LED technology is widely used in professional lighting fixtures such as spotlights, Fresnel lights, panel lights, and studio floodlights. It is valued for its smooth light output, high intensity, and improved thermal performance. In cinema environments, lighting must not create harsh shadows or inconsistent color temperatures. Chip On Board LED helps achieve soft yet powerful illumination that enhances visual storytelling.

How does Chip On Board LED Work?

Chip On Board LED works by mounting multiple LED semiconductor chips directly onto a thermally conductive substrate, usually made of aluminum or copper. These chips are connected electrically and arranged in a compact configuration. After mounting, the chips are covered with a phosphor coating layer. This coating converts the blue light emitted by the chips into white light or other color temperatures required for specific applications.

When electrical current flows through the LED chips, electrons move across the semiconductor material and release energy in the form of light. Because many chips are combined into a single module, the light output is concentrated and uniform. Unlike traditional LED packages where individual diodes are visible, Chip On Board LED produces a seamless lighting surface.

In cinematic electronics, this seamless output is important for reducing multiple shadow effects. When lighting actors or sets, filmmakers require a continuous and even beam. Chip On Board LED ensures that the light appears as a single source, which improves beam control and diffusion.

Heat management is another important aspect of its operation. Because many chips are placed closely together, heat generation can be significant. Therefore, the substrate acts as a heat sink, drawing heat away from the chips. Efficient thermal dissipation improves lifespan and maintains brightness stability during long filming sessions.

Drivers are used to regulate voltage and current supplied to the Chip On Board LED module. Stable electrical supply ensures consistent brightness and color performance, which is essential in cinema production where lighting continuity between scenes must be maintained.

What are the Components of Chip On Board LED?

Chip On Board LED modules consist of several key components that work together to produce reliable illumination.

LED Chips: These are tiny semiconductor devices that emit light when electric current passes through them. In Chip On Board LED, multiple chips are mounted directly onto a substrate without individual packaging.

Substrate or Base Board: This is typically made of metal core printed circuit board material such as aluminum. It provides mechanical support and excellent heat dissipation.

Phosphor Coating Layer: This layer covers the LED chips and converts the emitted blue light into white or other desired color temperatures. The thickness and composition of this layer influence color rendering and uniformity.

Electrical Contacts: These are conductive traces that connect the chips in series or parallel configuration to ensure proper voltage and current flow.

Encapsulation Material: A protective resin or silicone layer seals the chips from environmental factors such as moisture and dust.

Heat Sink: Though sometimes external, the heat sink is essential for transferring heat away from the LED module. In cinematic lighting fixtures, large heat sinks or active cooling systems are often integrated.

Driver Circuit: This regulates electrical input and protects the module from voltage fluctuations.

Together, these components create a robust lighting unit suitable for demanding cinema applications.

What are the Types of Chip On Board LED?

Chip On Board LED modules are available in various types depending on design, color output, and application requirements.

Single Color Chip On Board LED: These produce a fixed color temperature such as warm white, neutral white, or cool white. They are widely used in studio lights and stage spotlights.

Tunable White Chip On Board LED: These allow adjustment of color temperature, enabling filmmakers to match daylight or tungsten lighting conditions.

RGB Chip On Board LED: These combine red, green, and blue chips to create dynamic color effects. They are often used in stage lighting and creative cinematic environments.

High Power Chip On Board LED: Designed for intense illumination, these modules are used in professional film lighting equipment.

Waterproof Chip On Board LED: These are sealed for outdoor film shoots or architectural lighting around cinema buildings.

Miniature Chip On Board LED: Compact modules designed for portable or handheld lighting equipment.

Each type supports different cinematic lighting objectives, from natural scene illumination to dramatic artistic effects.

What are the Applications of Chip On Board LED?

Chip On Board LED technology has broad applications across the cinema industry and related fields.

Film Production Lighting: Used in studio lights, key lights, fill lights, and backlights to illuminate actors and sets.

Theater and Stage Lighting: Provides focused and uniform beams for stage performances and live cinema events.

Cinema Hall Ambient Lighting: Installed in walls, ceilings, and aisles to create comfortable viewing environments.

Projection Room Lighting: Ensures adequate lighting for equipment maintenance without affecting screen quality.

Architectural Lighting: Used for illuminating cinema exteriors and lobby areas.

Portable Lighting Equipment: Handheld LED panels for on location shooting.

Broadcast Studios: Television and streaming studios also rely on Chip On Board LED modules for consistent lighting.

Its versatility makes it essential in modern cinematic electronics systems.

What is the Role of Chip On Board LED in Cinema Industry?

Chip On Board LED plays a transformative role in the cinema industry. Lighting is one of the most important elements in filmmaking. It influences mood, tone, clarity, and audience perception. Chip On Board LED enables filmmakers to achieve professional lighting quality with energy efficiency and compact equipment.

In film production, consistent light output is critical. Scenes often require repeated takes, and lighting must remain stable throughout. Chip On Board LED offers minimal brightness fluctuation and reliable color rendering.

High Color Rendering Index performance ensures accurate skin tones and costume colors. This is especially important in digital cinematography, where cameras capture fine color details.

The compact structure allows lighting designers to place powerful lights in limited spaces. It also reduces equipment weight, making it easier to adjust lighting positions during shoots.

In cinema halls, Chip On Board LED contributes to energy efficient ambient lighting systems that enhance audience comfort without distracting from the screen.

Overall, Chip On Board LED supports creativity, efficiency, and technological advancement within cinematic electronics.

What are the Objectives of Chip On Board LED?

The objectives of Chip On Board LED technology in cinematic electronics focus on performance, efficiency, and visual quality.

One objective is to deliver high luminous output from a compact module. This allows intense lighting without bulky fixtures.

Another objective is to improve thermal management for longer lifespan and stable operation.

Energy efficiency is a major objective. Cinema production often involves extended lighting hours, and reducing power consumption lowers operational costs.

Uniform light distribution is another key objective. This eliminates multiple shadow effects and ensures smooth scene illumination.

Color accuracy and tunability are important objectives for filmmakers who require precise lighting control.

Durability and reliability also guide the development of Chip On Board LED modules.

What are the Benefits of Chip On Board LED?

Chip On Board LED offers numerous benefits in cinematic applications.

It provides higher brightness levels compared to traditional LED packaging methods.

The uniform light output reduces glare and creates smoother shadows.

Improved heat dissipation enhances longevity and reduces maintenance costs.

Compact design enables lightweight and portable lighting equipment.

Energy efficiency reduces electricity usage and supports sustainable cinema practices.

Better color rendering enhances film quality and visual storytelling.

Reduced wiring complexity simplifies fixture design.

These benefits make Chip On Board LED a preferred choice for modern cinema lighting systems.

What are the Features of Chip On Board LED?

Chip On Board LED modules include several advanced features.

High chip density increases luminous intensity.

Wide beam angle provides broad and even illumination.

High Color Rendering Index ensures accurate color reproduction.

Compact and integrated design reduces fixture size.

Excellent thermal conductivity maintains performance stability.

Dimmable functionality allows smooth brightness control.

Compatibility with modern driver circuits ensures flexible integration.

Long operational lifespan reduces replacement frequency.

These features collectively enhance cinematic lighting quality and reliability.

What are the Examples of Chip On Board LED?

Examples of Chip On Board LED applications can be seen in professional lighting equipment produced by leading brands.

Aputure manufactures high performance COB LED lights widely used in independent filmmaking and studio production.

ARRI integrates advanced LED technologies including COB modules into its professional lighting systems.

Godox produces affordable COB LED lighting solutions suitable for cinema and broadcast environments.

These examples demonstrate how Chip On Board LED technology is implemented in real world cinematic electronics equipment.

What is the Definition of Chip On Board LED?

Chip On Board LED is defined as a lighting technology in which multiple LED semiconductor chips are directly mounted onto a single substrate to form a high intensity, uniform light emitting module without individual chip packaging.

What is the Meaning of Chip On Board LED?

The meaning of Chip On Board LED refers to the method of assembling LED chips directly onto a circuit board rather than enclosing each chip in a separate casing. This approach enhances brightness, thermal efficiency, and uniformity of light output, making it suitable for professional lighting applications including cinematic electronics.

What is the Future of Chip On Board LED?

The future of Chip On Board LED in the cinema industry is promising. As digital filmmaking advances, demand for high efficiency and color accurate lighting continues to grow.

Innovations are focusing on improved phosphor materials, higher luminous efficacy, and smarter driver integration. Integration with intelligent lighting control systems will allow precise scene based adjustments.

Miniaturization will enable even more compact fixtures without compromising brightness. Enhanced thermal materials will extend lifespan and reliability.

Sustainable energy goals will encourage wider adoption of energy efficient LED systems in cinema halls and production studios.

Chip On Board LED is expected to remain a cornerstone of cinematic electronics due to its balance of performance, efficiency, and creative flexibility.

Summary

- Chip On Board LED mounts multiple LED chips directly onto a single substrate.

- It provides high brightness and uniform light output.

- Efficient thermal management improves lifespan and stability.

- It is widely used in film production, stage lighting, and cinema halls.

- High color rendering enhances visual storytelling.

- Compact design supports portable and flexible lighting systems.

- Energy efficiency reduces operational costs.

- Leading lighting brands integrate Chip On Board LED in professional equipment.

- The technology continues to evolve with improved materials and smart controls.

- Chip On Board LED plays a critical role in modern cinematic electronics within the cinema industry.