What is Air Core Inductor?

An air core inductor is an inductor that uses air as its magnetic core material instead of ferrite, iron powder, or laminated steel. In simple words, it is a coil of conductive wire shaped in a loop, spiral, helix, or flat pancake style, designed to store energy in a magnetic field when electric current flows through it. Because there is no solid magnetic material inside the coil, air core inductors avoid core related problems such as magnetic saturation and most core losses. This makes them especially useful for high frequency circuits where stability, linearity, and clean signal behavior matter.

In the broader world of inductors, air core designs are often chosen when the goal is precision and signal purity rather than maximum inductance in a small size. They are common in radio frequency circuits, tuned filters, oscillators, impedance matching networks, and high quality audio crossover networks. In cinematic electronics under the cinema industry, air core inductors show up in areas where filmmakers and exhibitors rely on clean, reliable signal paths and controlled electromagnetic behavior. That includes audio processing and amplification, microphone and wireless audio systems, camera and lens control accessories, LED lighting drivers, switching power supplies for production gear, and signal conditioning modules that keep noise out of sensitive audio and video chains.

Core material: Air core inductors use no ferromagnetic core, so inductance is generally lower compared to ferrite core inductors of similar size, but performance remains more linear across current levels.

Frequency behavior: Air core inductors often behave better at higher frequencies because there are fewer core losses and fewer nonlinearities to distort signals.

Signal cleanliness: Air core inductors reduce certain distortions and avoid saturation, which can be valuable in cinema grade audio and RF systems.

Why it matters for cinema: Cinematic electronics often operate in challenging environments with many wireless devices, high power lighting, motors, and switching supplies all close together. Air core inductors help engineers build filters and resonant circuits that keep unwanted noise out while preserving signal integrity.

How does Air Core Inductor Work?

An air core inductor works based on electromagnetism. When current flows through a coil, it creates a magnetic field around the wire. If the current changes, the magnetic field changes. A changing magnetic field induces a voltage that opposes the change in current. This is the basic behavior of inductance.

In cinema equipment, this behavior is useful because many electronics need to smooth currents, block high frequency noise, shape audio frequency response, or create tuned circuits that select desired radio channels. An air core inductor does this without a magnetic core, so the magnetic field is created and stored mainly in the air around and inside the coil.

Inductive opposition: An inductor resists changes in current. If current tries to increase quickly, the inductor pushes back by generating an opposing voltage. If current tries to decrease quickly, it pushes back in the opposite direction.

Energy storage: The inductor stores energy in its magnetic field while current flows. When the circuit changes, the stored energy can be released back into the circuit.

No saturation effect: Since air does not saturate the way ferromagnetic materials do, an air core inductor remains more linear. This means the inductance stays more consistent even when current changes.

Less core loss: Ferromagnetic cores can have hysteresis loss and eddy current loss, especially at higher frequencies. With air core inductors, these losses are much lower, though the coil still has resistive losses due to wire resistance.

Self resonance: Every real coil also has stray capacitance. At some frequency, the coil behaves like a resonant circuit, which can limit its useful frequency range. Good design and construction help push this self resonant frequency higher.

In cinematic electronics, these principles show up in practical ways. For example, a filter in a microphone preamp can use inductors and capacitors to reduce radio interference. A crossover network in a cinema speaker uses inductors to route low frequencies to the woofer and higher frequencies to other drivers. An RF front end in a wireless receiver uses air core coils to tune the circuit to a selected frequency band with high accuracy.

What are the Components of Air Core Inductor?

An air core inductor may look simple, but its performance depends on many construction details. The main components and design elements are closely tied to how the inductor is made and how it will be used in a circuit.

Coil conductor: The wire is usually copper because of its low resistance. Sometimes the wire is silver plated to improve high frequency performance due to skin effect. The wire can be solid, stranded, or litz wire depending on frequency and current needs.

Coil form: Many air core inductors are wound around a non magnetic former such as plastic, ceramic, fiberglass, or cardboard. Some are self supporting coils with no former, relying on a rigid wire and varnish bonding. The former gives shape stability and helps maintain consistent spacing.

Turns and winding pattern: The number of turns strongly affects inductance. The winding pattern also matters. Close wound coils increase inductance but also increase parasitic capacitance. Spaced windings reduce capacitance and often improve high frequency behavior.

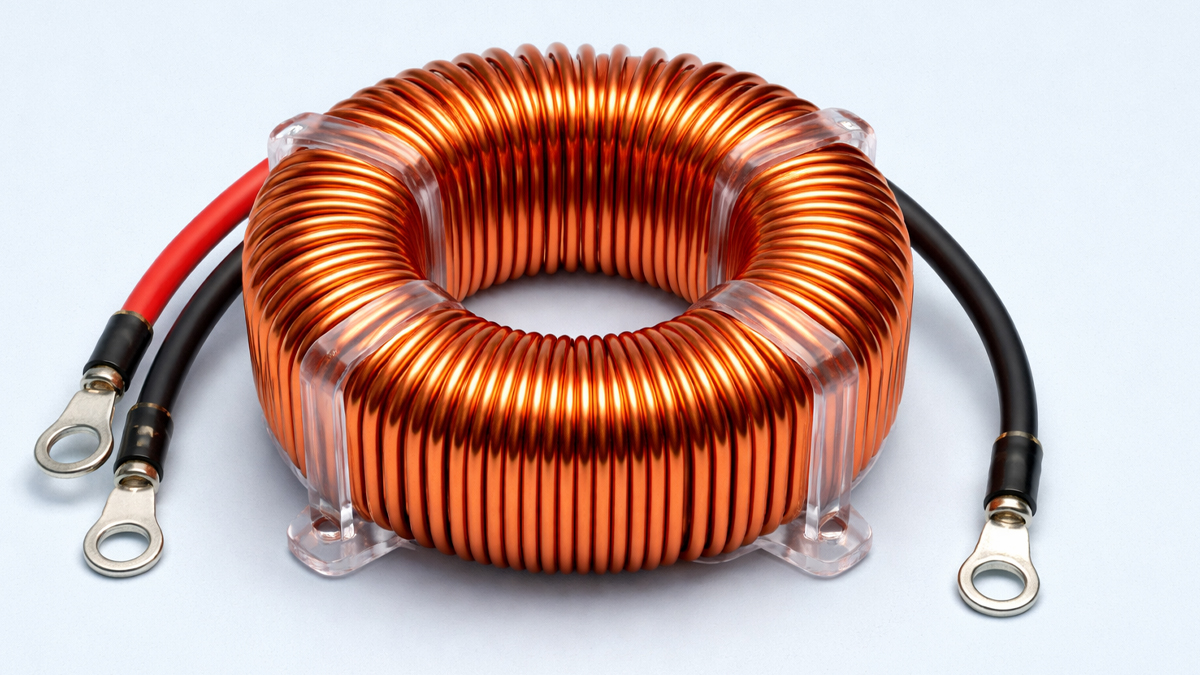

Coil geometry: Common shapes include solenoid coils, toroidal air coils, and flat spiral coils. Geometry affects magnetic field distribution, inductance, and coupling to nearby components.

Leads and terminals: The coil ends connect to the circuit through leads, pins, solder lugs, or surface mount pads. Lead length and routing can affect RF behavior and noise pickup.

Mechanical support and insulation: Varnish, epoxy, or coatings may be applied to hold the windings in place and prevent vibration. Insulating enamel on magnet wire prevents short circuits between turns.

Shielding and spacing environment: Although not part of the inductor itself, air core inductors often require careful placement and spacing on a circuit board. Nearby metal parts can change inductance and increase losses. In cinema gear, proper layout is crucial because many components are packed tightly in racks, cameras, and portable transmitters.

Thermal management: High current air core inductors may heat up due to copper losses. Designers use thicker wire, better airflow, or mounting methods that help dissipate heat.

Each of these elements influences electrical characteristics such as inductance value, tolerance, quality factor, current rating, and frequency response. In cinematic electronics, these characteristics matter because audio and RF systems are sensitive to distortion and noise. A small change in inductor behavior can alter filter response, audio crossover accuracy, or receiver tuning stability.

What are the Types of Air Core Inductor?

Air core inductors come in several types, mainly based on how they are built and where they are used. Even though all of them share the same principle of using air as the main magnetic medium, their shapes and construction methods make them suitable for different cinema related applications.

Solenoid air core inductor: This is the classic coil shape, a helix wound on a cylinder. It is commonly used in RF circuits, test equipment, and tuned networks. It can be adjusted in some designs by stretching or compressing the coil slightly to fine tune inductance.

Spiral or pancake air core inductor: This is a flat spiral coil, often used where height must be low, such as compact devices and planar circuits. It can be found in high frequency boards and some compact filter designs.

Self supporting air core inductor: This type has no former, and the coil holds its shape through rigid wire, bonding varnish, or epoxy. It is often used in audio crossovers because it can handle higher currents with less mechanical buzz when well secured.

Printed air core inductor: Some inductors are formed as traces on a printed circuit board. These are common in RF and microwave circuits where precise geometry is possible. They are small and consistent, though inductance values are limited.

Air toroid style coil: A toroidal shape made without a magnetic core. It can reduce stray magnetic fields compared to an open solenoid, which can be useful in audio to reduce coupling into nearby circuits.

Variable air core inductor: This design allows adjustment. Some use a movable slug made of non magnetic material or a mechanical system that changes coil spacing. Many classic radio circuits use variable inductors for tuning.

High current air core inductor: Built with thick wire, sometimes rectangular cross section, designed to handle large currents such as speaker crossovers and power electronics. In cinema sound systems, this type helps in speaker networks that must deliver high power cleanly.

High Q RF air core inductor: Built for low loss and high selectivity, used in RF filters and oscillators. In wireless audio for film sets, high Q inductors can help achieve better channel selection and lower noise.

Choosing the right type depends on frequency, current, physical space, and how sensitive the system is to magnetic coupling. Cinema environments can be crowded with power cables, lighting dimmers, wireless transmitters, motors, and digital equipment. Type selection and placement help keep audio and video systems stable.

What are the Applications of Air Core Inductor?

Air core inductors are widely used across electronics, particularly where frequency performance and linearity matter. In cinematic electronics under the cinema industry, they show up in both production and exhibition equipment.

RF tuning and filtering: Wireless microphones, in ear monitors, camera hop systems, and wireless timecode units depend on RF front ends. Air core inductors are used in resonant circuits and filters that select the desired frequency and reject interference.

Audio crossovers and speaker networks: In cinema speakers, passive crossovers often use inductors to direct low frequencies to woofers and keep mid and high frequencies away from them. Air core inductors are popular because they have low distortion and do not saturate under high power audio currents.

Noise suppression and EMI filtering: Film sets and theaters contain many switching devices such as LED drivers, dimmers, motor controllers, and switching power supplies. Air core inductors can be part of LC filters that reduce conducted and radiated noise, keeping sensitive audio and video circuits clean.

Impedance matching networks: Audio and RF systems sometimes require impedance matching for maximum power transfer or best signal integrity. Air core inductors are used in matching networks for antennas, transmitters, and receivers used on sets and in broadcast support systems.

Oscillators and signal generation: Many circuits that generate clocks or reference signals use inductive elements in resonance. Air core inductors can be used when high frequency stability and low loss are needed.

Test and measurement equipment: Cinematic electronics teams often use spectrum analyzers, RF scanners, audio analyzers, and calibration tools. Air core inductors appear inside these devices in filters and tuned sections.

High frequency power converters: While many power inductors use ferrite cores for higher inductance density, some high frequency specialized converters or resonant power stages may use air core designs to avoid core losses at very high frequencies, though this is more niche.

Camera and lens accessory electronics: Focus motors, wireless follow focus systems, and camera control units require filtering, stable power rails, and noise management. Air core inductors can support these tasks, especially in filters where core nonlinearity is undesirable.

Lighting control and LED equipment: Modern cinematic lighting uses high frequency switching. Air core inductors can be used in certain filter sections to reduce audible noise and to keep switching artifacts from leaking into audio or control lines.

These applications share a theme. Cinema work demands reliability in noisy electromagnetic environments and consistent results across takes and screenings. Air core inductors help engineers achieve that by providing predictable inductance without the risks of saturation and many core losses.

What is the Role of Air Core Inductor in Cinema Industry?

The cinema industry is full of electronics that must work together without interference. A film set may have dozens of wireless devices, high power lights, motorized rigs, and computers running near sensitive microphones and cameras. A cinema hall may have high power audio amplifiers, digital projection systems, servers, networking equipment, and lighting control in the same building. Air core inductors support this world by helping maintain signal integrity, reduce distortion, and control unwanted electromagnetic noise.

Maintaining clean audio in production: Dialogue is fragile. Even small interference can ruin a take. Air core inductors contribute to filters and RF sections in wireless receivers and microphone circuits. Their linear behavior helps keep the audio path clean and reduces the chance of introducing subtle distortion.

Supporting wireless reliability: Wireless systems must reject interference and stay tuned accurately. Air core inductors are used in tuned circuits and filters. Because they avoid magnetic core saturation, they behave consistently even when signals vary, supporting stable RF performance.

Improving cinema sound reproduction: In theaters, sound systems must be powerful and accurate. Passive speaker crossovers may carry significant current. Air core inductors are valued here because they do not saturate under high audio currents, which helps keep bass response controlled and avoids compression or distortion.

Reducing electromagnetic noise in mixed equipment environments: LED lighting systems and switching supplies can generate high frequency noise. Air core inductors can be used in filters that block noise from reaching audio preamps, digital converters, and control lines.

Enhancing precision in filters and equalization: Some audio circuits use inductors in equalization networks. In these cases, air core inductors can provide stable values and a pleasing linear response, supporting predictable tuning.

Helping equipment survive tough conditions: Production equipment is moved, bumped, and run on batteries. An inductor that avoids core cracking issues and avoids saturation can be an advantage. Mechanical stability still matters, so secure mounting and varnish bonding are important.

Supporting RF compliance and clean set operation: Film sets can become accidental interference factories if gear is noisy. Well designed filtering that includes air core inductors helps reduce emissions and improves coexistence between departments such as camera, sound, lighting, and communications.

In simple terms, the role of an air core inductor in the cinema industry is to help the electronics behave politely. It helps systems reject noise, stay linear, and preserve signal quality, whether the signal is a whisper of dialogue, a high power soundtrack, or a radio frequency carrier carrying timecode.

What are the Objectives of Air Core Inductor?

Air core inductors are chosen to meet specific engineering objectives. In cinematic electronics, those objectives often align with consistent performance, low distortion, and high frequency capability.

Linearity objective: Maintain inductance that stays stable as current changes, avoiding saturation related changes that can distort signals.

Low distortion objective: Support audio and RF circuits with minimal nonlinear behavior, helping keep sound and signal paths clean.

High frequency objective: Provide good performance at higher frequencies by avoiding many core related losses and hysteresis effects.

Stable tuning objective: Enable tuned circuits that remain predictable over time and over varying signal levels, important in wireless systems and precision filters.

Low loss objective: Achieve a higher quality factor in certain designs, improving selectivity in RF filters and reducing heat in resonant circuits.

Noise control objective: Help create effective LC filters that suppress switching noise from lighting and power systems, protecting audio and video electronics.

Repeatability objective: Provide inductors that behave consistently from unit to unit when properly manufactured, supporting reliable cinema gear performance.

Safety and robustness objective: Avoid core saturation and reduce certain failure modes related to magnetic materials, though mechanical stability still needs proper design.

These objectives are not abstract. They translate into real benefits on set and in theaters, such as fewer dropouts in wireless audio, cleaner soundtrack reproduction, and reduced hum or buzz caused by interference.

What are the Benefits of Air Core Inductor?

Air core inductors offer several strong benefits, especially when used in the right place.

No magnetic saturation: Air does not saturate like ferrite or iron, so the inductor remains linear across a wide range of currents. This is very valuable in audio crossovers and high fidelity audio paths.

Low core losses: With no ferromagnetic core, there is no hysteresis loss and much less eddy current loss. This makes air core inductors suitable for high frequency work.

Low distortion in audio: Air core inductors tend to introduce less harmonic distortion compared to some core based inductors, which is why audio designers often prefer them for speaker crossovers.

Better high frequency behavior: Many air core designs can achieve high quality factor at RF and remain predictable across frequency ranges where core materials can become lossy.

Good temperature stability: While copper resistance changes with temperature, there is no core permeability drift. This can help stability in tuned circuits and filters.

Predictable inductance: With a well controlled geometry, air core inductance is easier to model and less dependent on material properties.

Reduced risk of magnetic core noise: Some magnetic cores can create audible noise under certain conditions due to magnetostriction. Air core inductors avoid that core based noise source, though the coil itself can still vibrate if not secured.

Cleaner electromagnetic behavior for precision circuits: In sensitive RF and audio circuits, reducing nonlinear magnetic effects can improve clarity and reliability.

In cinema related systems, these benefits contribute to clearer sound, stable wireless operation, and better control of interference in complex equipment environments.

What are the Features of Air Core Inductor?

Air core inductors have distinct features that influence how designers use them.

Coreless construction: The main feature is the absence of a ferromagnetic core, leading to linear inductance and low core losses.

Lower inductance density: For the same inductance value, air core inductors often require more turns or larger size than core based inductors.

High Q potential: With careful design using thick wire, spaced turns, and low loss construction, air core inductors can achieve high quality factor at RF.

Wide current handling without saturation: Particularly useful for audio crossovers and some power filtering roles where currents can be large.

Sensitivity to nearby materials: Because the magnetic field extends into space, nearby metal can change inductance and increase loss. Placement and spacing are part of the feature set because they matter so much.

Higher electromagnetic radiation and pickup: Compared to shielded core types, air coils can couple more easily to nearby circuits. This can be a feature or a drawback, depending on whether coupling is desired.

Adjustability in some designs: Some air core coils can be tuned by changing spacing or physical shape, which is useful in prototypes and RF tuning.

Construction options: Can be wound on formers, self supporting, or printed on circuit boards, offering flexibility for different cinema equipment designs.

Mechanical stability considerations: Windings can move due to vibration or thermal cycling if not secured. Good designs include varnish, epoxy, or clamps to keep the coil stable, important in production gear that travels.

These features help explain why air core inductors are often chosen for quality sensitive tasks and why designers must handle them carefully in layout and mounting.

What are the Examples of Air Core Inductor?

Air core inductors appear in many real world cinema and cinematic electronics scenarios. Below are practical examples explained in simple terms, without listing them as bullets, so you can imagine where they sit inside equipment.

Cinema loudspeaker passive crossover coil: In a high power theater speaker, a large air core inductor made with thick copper wire is used in series with the woofer. This coil blocks higher frequencies and lets the woofer focus on bass and low midrange. Because the soundtrack can be powerful, the coil must carry high current without saturating. Air core helps maintain clean bass without compression from core saturation.

Wireless microphone receiver front end coil: A compact high Q air core inductor can be part of the tuned circuit at the input of a wireless receiver. It works with capacitors to form a resonant filter that selects the desired channel and rejects unwanted signals. This improves reliability on crowded sets with many transmitters.

RF filter in camera hop systems: Camera hop transmitters and receivers send audio from sound department to camera. Air core inductors in bandpass filters can help ensure the system stays in its intended frequency band and reduces interference from nearby devices.

EMI filter in LED lighting power unit: A lighting power supply may include a filter section that reduces switching noise on the power lines. An air core inductor, paired with capacitors, can reduce high frequency ripple so it does not travel into audio gear through shared power distribution.

Audio equalization networks in analog processing: Some analog audio processors use inductor based equalization circuits. In these cases, air core inductors can be chosen to reduce distortion and keep the EQ curve stable.

Intercom and communications gear: On a set, communications systems rely on stable RF and clean audio. Air core inductors can be used inside RF sections and audio filtering blocks to improve performance in noisy environments.

Antenna matching network in wireless video or audio: Some systems need matching networks to optimize antenna performance. Air core inductors are common in these networks because they provide predictable inductance and can be adjusted during tuning.

Test instruments used by cinema engineers: RF scanners, spectrum analyzers, and audio analyzers often include tuned filters and resonant networks. Air core inductors are used in those sections, especially where high frequency performance and low loss are required.

These examples show that air core inductors are not just academic components. They are quietly present in many parts of the cinema workflow, from capturing dialogue to delivering sound in a theater.

What is the Definition of Air Core Inductor?

An air core inductor is an electrical component consisting of a coil of conductive wire designed to provide inductance, where the magnetic field is formed primarily in air and there is no ferromagnetic core material used to concentrate the magnetic flux.

This definition highlights the two key points. It is a coil that provides inductance, and it uses air as the core medium. Because of that, the component tends to be more linear and better suited for high frequency and low distortion applications, though it is typically larger for the same inductance compared to core based designs.

What is the Meaning of Air Core Inductor?

The meaning of air core inductor is simple when broken down. Inductor means a component that produces inductance, which is the ability to store energy in a magnetic field and resist changes in current. Air core means the coil does not rely on a magnetic material inside it. So the meaning is a coil based component that performs inductive behavior using air as the main magnetic path.

In practical terms, it means you are choosing signal purity and predictable behavior over compact size and very high inductance values. This is why air core inductors are respected in audio crossover design and in certain RF circuits used in production and cinema equipment.

In cinematic electronics, the meaning also connects to reliability. When the environment is full of strong currents and many radio devices, a component that stays linear and stable helps the whole system behave more consistently.

What is the Future of Air Core Inductor?

The future of air core inductors remains strong, especially as cinema technology keeps pushing toward higher fidelity, denser wireless environments, and tighter electromagnetic compatibility requirements. Even though many applications use ferrite core inductors for compactness, air core designs keep their place because their fundamental advantages are tied to physics rather than trends.

Growing wireless density on sets: Film sets keep adding more wireless microphones, timecode systems, control links, and communications. As frequency planning becomes more complex, high quality RF filters and tuned circuits remain important. Air core inductors will continue to support these RF front end designs because they can deliver stable, linear performance at high frequencies.

Higher expectations for audio fidelity: The industry continues to demand clearer dialogue capture and more immersive theater sound. Speaker manufacturers and audio engineers still value low distortion crossovers. Air core inductors will remain a premium choice for passive crossovers in many high end cinema and studio monitors.

Improved materials and manufacturing: Better coil winding machines, tighter tolerances, and improved coatings will make air core inductors more consistent and more rugged. For portable production gear, mechanically stable coils reduce drift and noise.

More compact designs with smarter geometry: While air core inductors are larger than core based designs for the same inductance, designers can optimize geometry, spacing, and conductor shape. Printed and planar air core inductors will likely expand in certain RF modules where board space and repeatability matter.

Better electromagnetic design practices: As productions use more LED lighting and switching power supplies, electromagnetic interference control will become even more critical. Air core inductors in specialized filter sections can help meet stricter noise limits and protect sensitive audio.

Hybrid approaches: The future may include more systems that use both air core and magnetic core inductors, each in the part of the circuit where it performs best. For example, a compact ferrite inductor may handle bulk power conversion, while an air core inductor handles the final high frequency filtering or resonance where linearity matters.

Sustainability and serviceability: Air core inductors are relatively simple components. In some cases they can be easier to inspect and replace compared to specialized core designs. As cinema companies focus on maintaining gear longer, robust and understandable components may be appreciated.

Overall, the future of air core inductors in cinematic electronics is not about replacing everything else. It is about continuing to serve the roles where linearity, low distortion, and high frequency stability matter most.

Summary

- Air core inductors are coils that store energy in a magnetic field using air as the core medium.

- They resist changes in current and are widely used for filtering, tuning, and signal shaping.

- Their biggest advantage is linear performance because they do not saturate like magnetic core inductors.

- They are especially useful in high frequency RF circuits and low distortion audio applications.

- In the cinema industry they support wireless reliability, clean audio capture, speaker crossovers, and EMI control.

- Proper mechanical mounting and careful layout matter because air core coils can couple to nearby components.

- The future remains strong as cinema workflows demand more wireless capacity, better fidelity, and stricter noise control.