What is Brushed DC Motor?

A brushed DC motor is an electric motor that converts direct current electrical energy into mechanical rotation using physical contact between brushes and a rotating commutator. The commutator and brushes act like an automatic switching system that keeps the motor producing torque in the same rotational direction as the rotor turns.

In simple terms, a brushed DC motor is built to do one main job: take power from a DC source such as a battery or a DC power supply and turn a shaft smoothly enough to drive something useful. That something can be a fan, a pump, a gear train, a wheel, a camera accessory, or a precision mechanism inside cinematic electronics used in the cinema industry.

Core idea: Electrical current flows through coils on the rotor, a magnetic field forms, the rotor is pushed by magnetic forces, and the commutator flips the current direction at the right moments so the pushing continues as rotation rather than stopping at a dead point.

Why it matters in cinematic electronics: Many film and video tools need dependable, controllable rotation in a compact form factor. Brushed DC motors remain widely used because they are easy to power, easy to control with basic circuits, cost effective, and available in many sizes.

How does Brushed DC Motor Work?

A brushed DC motor works by using electromagnetic forces created when current flows through conductors in a magnetic field. The motor is designed so that these forces generate continuous rotational torque on the rotor.

Electrical to magnetic conversion: When DC current flows through the rotor windings, the windings become an electromagnet. This electromagnet interacts with the magnetic field of the stator, which can be created by permanent magnets or by field windings. The interaction produces a force on the conductors, and because the conductors are arranged around a rotating rotor, the forces combine to produce torque.

Commutation process: The most defining part of a brushed DC motor is commutation. As the rotor rotates, the commutator segments rotate with it. Brushes, usually made of carbon or graphite composites, press against the commutator. The commutator is wired to the rotor windings in a way that changes which winding receives current as the rotor turns. This switching keeps the magnetic polarity of the rotor aligned so that torque continues in the same direction.

Torque generation cycle: At one moment, a specific rotor coil receives current and becomes magnetized. The coil is pushed or pulled by the stator field. As the rotor turns, that coil moves into a position where it would no longer produce useful torque if current stayed the same. The commutator then switches the current to a different coil and reverses current direction in the right places. This continues repeatedly, creating smooth rotation.

Speed control principle: Motor speed depends mainly on applied voltage and load. Increasing voltage usually increases speed, while increasing mechanical load reduces speed and increases current draw. For many cinema industry tools, this simple relationship is useful because speed can be controlled using methods like pulse width modulation.

Real world behavior: In practice, the brushes introduce friction and electrical noise, and the commutation creates tiny sparks at the brush contact point. These effects shape how brushed DC motors are chosen, filtered, shielded, and maintained in professional cinematic electronics.

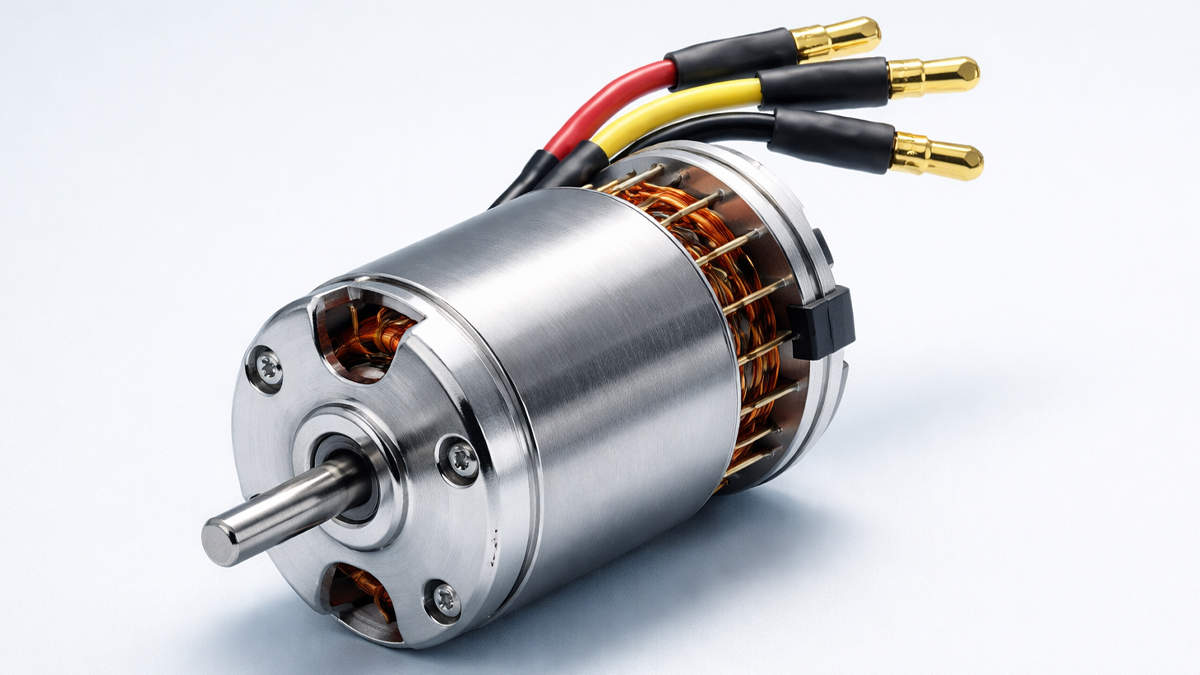

What are the Components of Brushed DC Motor?

A brushed DC motor has several key components that work together to create rotation. Each part has a specific purpose, and understanding them helps when selecting a motor for cinema industry applications.

Stator: The stator is the stationary part of the motor that provides a magnetic field. In many small motors, it uses permanent magnets attached to the inside of the housing. In larger motors, it may use field windings that create an electromagnet.

Rotor or armature: The rotor is the rotating part. It carries the windings that receive current through the commutator. When the windings are energized, they create a magnetic field that interacts with the stator field to produce torque.

Commutator: The commutator is a segmented conductive cylinder attached to the rotor. Each segment connects to a coil in the armature. Its job is to switch current from one coil to another as the rotor turns, ensuring continuous torque.

Brushes: Brushes are conductive contacts that press against the commutator. They deliver current from the external power source to the rotating commutator. Brush material and spring pressure affect performance, noise, and lifetime.

Shaft: The shaft is connected to the rotor and transmits mechanical power to the load. In cinematic electronics, the shaft often drives gears, belts, pulleys, lead screws, or couplings.

Bearings or bushings: Bearings support the shaft and allow low friction rotation. Small motors may use sleeve bushings, while higher performance motors use ball bearings for better efficiency, lower noise, and longer life.

Housing: The motor housing holds everything in alignment, supports the stator magnets or field structure, and provides mechanical protection. The housing also influences heat dissipation.

Windings: Windings are copper coils on the rotor. The number of turns, wire thickness, and winding pattern determine torque constant, speed constant, efficiency, and current draw.

End caps and brush holders: End caps close the motor, hold the bearings, and provide brush mounting structures. Brush holders keep brush alignment stable for consistent contact.

Optional suppression components: Some motors include capacitors or filter networks across terminals or between terminals and the housing to reduce electromagnetic interference. This is often important in cinema industry equipment where clean audio and stable wireless systems matter.

What are the Types of Brushed DC Motor?

Brushed DC motors can be classified by how the magnetic field is produced and how the field relates electrically to the armature. The different types have different torque characteristics, speed stability, and control behavior.

Permanent magnet brushed DC motor: This type uses permanent magnets for the stator field. It is common in compact cinematic electronics because it is efficient, small, and simple. It also has predictable control behavior with PWM drivers.

Series wound brushed DC motor: In this type, the field winding is connected in series with the armature winding. It produces very high starting torque, but speed can vary significantly with load. It is used when heavy starting loads are expected, though it is less common in precision cinematic tools.

Shunt wound brushed DC motor: Here, the field winding is connected in parallel with the armature. It provides better speed regulation, meaning the speed stays more stable when the load changes. This can be useful when consistent motion is required.

Compound wound brushed DC motor: Compound motors combine series and shunt field characteristics. They can provide good starting torque and better speed stability than series motors. They may appear in applications that need both strong acceleration and controlled running speed.

Separately excited brushed DC motor: In this design, the field winding is powered from a separate source. This allows independent control of field strength and armature voltage, enabling a wider speed range and refined control. It is more common in industrial settings, but the concept matters when designing advanced cinema motion rigs.

Coreless brushed DC motor: A coreless motor has an armature winding without an iron core. This reduces inertia significantly, enabling fast response and very smooth low speed control. Coreless brushed motors are popular in precision applications such as compact gimbals, lens accessories, and micro motion systems, especially when rapid acceleration and minimal cogging are desired.

Gearmotor variants: Many brushed DC motors in cinema industry tools come as gearmotors. A gearbox is attached to the motor to reduce speed and increase torque. This is not a different electromagnetic type, but it is a common practical category when selecting a motor for follow focus drives, sliders, and compact actuators.

What are the Applications of Brushed DC Motor?

Brushed DC motors are used wherever controlled rotation is needed with DC power. Their applications span consumer electronics, industrial systems, vehicles, and specialized cinematic electronics.

Portable devices: Battery powered tools often use brushed DC motors because they operate directly from common battery voltages and are easy to control with compact driver circuits.

Actuators and mechanisms: When rotation must be converted into linear motion, brushed DC motors drive lead screws, racks, cams, or gear trains. This is common in focus, zoom, iris assist mechanisms, and camera support systems.

Fans and cooling modules: Many electronics require active cooling. Small brushed DC motors drive fans in older or cost sensitive designs. In cinema gear, cooling is critical for lights, monitors, and power distribution devices, although brushless fans are also common.

Pumps and fluid systems: Brushed motors can drive small pumps, including air pumps and fluid pumps. In production environments, they can appear in portable equipment, special effects rigs, and maintenance tools.

Robotics and motion control: Brushed motors are used in simple robots and motion platforms. They can be paired with encoders for closed loop control. Cinema motion control rigs sometimes use brushed solutions for auxiliary axes where cost and simplicity are priorities.

Automotive and industrial tools: Power windows, seat adjusters, drills, and small machine tools often use brushed DC motors. The same manufacturing ecosystem provides a wide range of motor sizes and gear options useful for custom cinema builds.

Educational and prototyping: Brushed motors are common in prototypes because they are easy to interface with microcontrollers, motor drivers, and power supplies. Many cinema industry innovations begin as prototypes where brushed motors are used for early testing.

What is the Role of Brushed DC Motor in Cinema Industry?

In the cinema industry, a brushed DC motor is often a behind the scenes workhorse that enables controlled movement, repeatable positioning, and mechanical automation inside cinematic electronics. Even when brushless systems dominate the highest end applications, brushed motors remain relevant in many accessories, compact mechanisms, and budget conscious or space constrained designs.

Camera movement systems: Sliders, mini dollies, compact pan tilt heads, and small motion rigs may use brushed DC gearmotors to move a camera smoothly along a rail or rotate a platform. With the right gearbox and controller tuning, brushed motors can deliver usable cinematic motion, especially for slower moves.

Lens control and focus systems: Follow focus devices, zoom assist modules, and iris control accessories can use brushed DC motors, particularly in compact or entry level designs. A motor coupled with gears or belts can rotate a lens ring. When paired with feedback sensors such as encoders or potentiometers, the system can achieve repeatable focus pulls and programmable marks.

Rig automation and accessory drives: Brushed motors can drive rotating filters, small turntables for product shots, time lapse systems, and controlled rigs for miniature cinematography. They can also appear in camera support tools, for example automatic height adjustment modules or motorized counterbalance mechanisms.

Props and practical effects: Many practical effects use small motors to animate props, open panels, rotate signs, move miniatures, or create mechanical motion on set. Brushed motors are easy to power from batteries, making them practical for mobile setups.

Why cinema environments care about motor behavior: Film sets care about noise, vibration, and electromagnetic interference. Brushed motors can produce audible brush noise and electrical noise from commutation. This does not automatically disqualify them, but it affects how they are mounted, isolated, filtered, and controlled. For example, a motor might be placed farther from microphones, enclosed, or driven with filtered PWM to reduce audible artifacts.

Integration within cinematic electronics: Cinematic electronics often include microcontrollers, wireless receivers, timecode devices, audio recorders, and sensitive sensors. A brushed motor system typically needs suppression capacitors, careful grounding, cable routing, and sometimes shielding to avoid interfering with audio and RF performance.

What are the Objectives of Brushed DC Motor?

The objectives of a brushed DC motor, especially within cinematic electronics for the cinema industry, can be understood as practical goals the motor helps achieve.

Motion generation objective: Provide reliable rotational motion that can be transferred to a mechanism, whether directly or through gears and belts.

Control simplicity objective: Enable straightforward speed and direction control using DC voltage changes or PWM drivers. This supports rapid integration into electronic designs.

Torque delivery objective: Deliver enough torque to start and maintain motion under load, especially when coupled with a gearbox for high torque applications such as camera sliders or lens rings.

Compactness objective: Fit into limited spaces inside camera accessories, compact rigs, or portable production tools.

Cost efficiency objective: Offer an economical motor solution that balances performance with production cost, especially important for scalable cinema accessories and entry level products.

Power source compatibility objective: Operate from common DC power sources used on set, such as battery packs and regulated DC outputs, without requiring complex multi phase drivers.

Response objective: Provide acceptable acceleration and deceleration performance for the target motion profile, whether that is slow cinematic movement or quick mechanical adjustment.

Maintainability objective: Allow serviceability in some designs where brushes can be replaced or where the motor can be swapped easily, reducing downtime for production tools.

What are the Benefits of Brushed DC Motor?

Brushed DC motors remain popular because they provide several clear benefits, especially when a design values simplicity, affordability, and practical controllability.

Simple control electronics: A brushed DC motor can be controlled with basic H bridge drivers, MOSFET switches, and PWM signals. This reduces circuit complexity compared to many brushless systems.

Wide availability: Brushed motors are manufactured in huge volumes. This results in many size options, shaft configurations, gearboxes, and voltage ratings.

Low initial cost: For many torque and size ranges, brushed motors are less expensive than equivalent brushless motors when considering both motor and driver cost.

Good low speed torque with gearing: When paired with a gearbox, brushed motors can provide strong torque at low output speeds, useful for smooth camera moves and lens control.

Direct DC power compatibility: They work naturally with batteries and DC supplies commonly used in portable film gear.

Predictable behavior: The relationship between voltage, speed, and load is relatively intuitive. This helps engineers and technicians tune systems quickly.

Fast prototyping: Because drivers and control methods are common, brushed motors are excellent for early stage prototypes of cinematic electronics.

Compact solutions: Small brushed motors and coreless variants can fit into tight spaces, enabling miniature actuators and hidden mechanisms.

What are the Features of Brushed DC Motor?

A brushed DC motor has features that define how it behaves, how it is integrated into systems, and what performance tradeoffs it brings.

Commutator based switching: The commutator and brushes automatically switch current in the rotor windings, allowing continuous torque without electronic commutation.

Bidirectional operation: Reversing the polarity of the supply reverses the motor direction. With an H bridge, direction control is simple and fast.

Speed controllability: Speed can be adjusted by changing supply voltage or using PWM. Many cinema tools use PWM for efficient speed control.

High starting torque: Many brushed motor designs provide strong starting torque, especially when current is available. This is useful for overcoming static friction in mechanical rigs.

Scalable design range: Brushed motors exist in micro sizes for tiny mechanisms and larger sizes for heavier loads.

Gearbox compatibility: Brushed motors pair well with spur gearboxes, planetary gearboxes, and worm gear drives. This expands their usefulness in controlled motion systems.

Noise and EMI considerations: Brush contact produces electrical noise and can generate EMI. In cinema industry devices, this feature becomes a design constraint that is managed with suppression, shielding, and careful layout.

Wear components: Brushes and commutators wear over time. This feature affects maintenance and lifetime planning for equipment that runs continuously.

Thermal characteristics: Like all motors, brushed motors generate heat from copper losses and mechanical friction. Housing design, ventilation, and duty cycle ratings matter in continuous filming setups.

Feedback integration: Brushed motors can be combined with encoders, tachometers, Hall sensors, or current sensing to create closed loop control for more precise cinematic motion.

What are the Examples of Brushed DC Motor?

Examples can be described by the kinds of brushed DC motors commonly used in real products and cinema related builds, without relying on brand specific claims.

Miniature brushed DC motor in a gearmotor module: A small cylindrical motor coupled to a metal or plastic gearbox. This is often used for compact sliders, small pan modules, and accessory drives where torque is needed at low speed.

Coreless brushed DC motor for precision actuation: A lightweight rotor design with very low inertia. This can be useful in quick response lens control modules or micro motion devices where smoothness at low speed is important.

Permanent magnet brushed DC motor for portable rigs: A typical permanent magnet motor powered by a battery pack, used in portable tools that need reliable operation and simple wiring.

Brushed DC motor driving a belt and pulley system: A motor that drives a timing belt to rotate a lens ring or move a carriage. Belt drives can reduce vibration transfer and allow flexible placement within a rig.

Brushed DC motor with encoder for repeatable moves: A motor integrated with an encoder on the shaft or motor body. This enables repeatable motion cues such as consistent focus marks or repeated slider moves.

Brushed DC motor inside practical effects props: Small motors used to animate on screen props, for example rotating dials, moving panels, or miniature mechanical motion for set pieces.

What is the Definition of Brushed DC Motor?

A brushed DC motor is defined as an electric motor that uses brushes and a commutator to deliver direct current to rotating armature windings, producing torque through interaction with a stator magnetic field and achieving continuous rotation through mechanical commutation.

This definition highlights the three essential points: it uses DC power, it uses brushes and a commutator for current switching, and it produces rotation through electromagnetic interaction.

What is the Meaning of Brushed DC Motor?

The meaning of brushed DC motor can be understood by breaking down the term into practical language.

Brushed: The motor uses brushes, which are stationary conductive parts that touch the rotating commutator to transfer electrical power.

DC: The motor is designed to run from direct current power sources such as batteries or DC supplies.

Motor: The device converts electrical energy into mechanical energy, typically rotational motion at a shaft.

So the meaning is a DC powered rotating machine where brushes provide the electrical connection to the rotating part, enabling the motor to keep producing torque as it spins.

In the context of cinematic electronics under the cinema industry, the meaning extends further: it is a compact and controllable motion source that can automate camera and lens related tasks, drive mechanical accessories, and enable repeatable movements that support storytelling and production efficiency.

What is the Future of Brushed DC Motor?

The future of brushed DC motors is shaped by the balance between their strengths and their limitations. While brushless motors continue to grow in popularity for high efficiency, low noise, and long life, brushed motors are not disappearing. Instead, they are evolving into more specialized roles.

Continued relevance in cost sensitive equipment: Entry level and mid range cinema accessories often prioritize affordability and simplicity. Brushed motors will likely remain common where performance requirements are moderate and where replacement is easy.

Growth in compact precision niches: Coreless brushed motors and high quality miniature gearmotors can remain attractive for ultra compact mechanisms. When designers need low inertia and simple control in small spaces, brushed solutions can still compete.

Better suppression and integration practices: As cinema sets become more electronics dense with wireless audio, video transmitters, and advanced sensors, motor systems will likely incorporate better EMI suppression, improved grounding standards, and more refined driver control to reduce interference.

Hybrid designs and smarter control: Brushed motors can be paired with encoders, current sensing, and control algorithms that compensate for load changes and reduce jitter. This can make brushed systems feel more precise, even if the motor itself is mechanically commutated.

Environmental and maintenance considerations: Because brushes wear, long duty cycle professional equipment may shift further toward brushless solutions. However, brushed motors can remain viable when duty cycles are intermittent or when the design allows quick motor replacement.

Cinema industry direction: High end motion control, stabilized heads, and premium lens control systems increasingly favor brushless motors for quietness and efficiency. Even so, brushed motors can remain present in auxiliary axes, secondary mechanisms, portable accessories, and practical effects where simplicity wins.

Summary

- A brushed DC motor converts DC electrical power into rotational motion using brushes and a commutator for mechanical current switching.

- It works by energizing rotor windings, creating magnetic forces against the stator field, and continuously switching current through commutation.

- Key components include stator, rotor or armature, commutator, brushes, shaft, bearings, housing, and windings, with optional EMI suppression parts.

- Common types include permanent magnet, series wound, shunt wound, compound wound, separately excited, coreless variants, and practical gearmotor configurations.

- Applications range from portable devices and actuators to robotics, pumps, fans, and many motion systems used in cinematic electronics.

- In the cinema industry, brushed motors support camera movement tools, lens control accessories, rig automation, and practical effects, with attention to noise and interference management.

- Objectives include dependable motion, simple control, sufficient torque, compact integration, cost efficiency, and compatibility with common DC power sources.

- Benefits include low cost, wide availability, straightforward drivers, predictable control behavior, and strong torque when geared.

- Features include bidirectional control, PWM speed control, high starting torque, gearbox compatibility, and the reality of brush wear and EMI considerations.

- The future likely keeps brushed motors relevant in cost sensitive and compact niches, while brushless motors expand in high end cinema systems that demand low noise and long service life.