What is Coreless DC Motor?

A coreless DC motor is a type of direct current motor that uses a rotor (armature) without an iron core. In a traditional DC motor, the armature winding is wrapped around an iron core that helps guide magnetic flux and produce torque. In a coreless DC motor, the winding is typically formed into a self supporting cylindrical basket or skewed coil structure that rotates inside a magnetic field. Because the heavy iron core is removed, the rotating part becomes much lighter and can accelerate and decelerate extremely quickly.

Coreless DC motors are known for fast response, smooth motion at low speeds, high efficiency in many small scale applications, and low electrical and mechanical time constants. These traits make them popular in precision devices where the motor needs to start instantly, stop cleanly, and follow control commands with minimal delay. In cinematic electronics, where motion control often needs to feel invisible to the audience, this kind of motor can be a quiet hero behind stable shots, precise focus moves, and repeatable camera motion.

Coreless designs are common in compact, high performance tools such as camera gimbals, lens control systems, handheld stabilizers, miniature robotics, and precision actuators. They are also used in places where you want minimal vibration and consistent torque. Since cinema production depends on accurate and repeatable movement, coreless DC motors fit naturally into many behind the scenes systems that shape what viewers ultimately see on screen.

Subtle motion is a major theme in modern filmmaking. Even a tiny jerk during a rack focus or a micro vibration in a stabilizer can be visible. Coreless DC motors help reduce those issues because they can respond quickly to control signals and can be engineered for smoother rotation, especially when paired with good gearing, encoders, and motor drivers.

How does Coreless DC Motor Work?

A coreless DC motor works by using electromagnetic force on current carrying conductors placed in a magnetic field. The motor driver sends DC current into the rotor winding. The winding sits inside a magnetic field produced by permanent magnets in the stator. When current flows through the winding, it experiences a force that produces torque, causing the rotor to rotate. To keep the rotor spinning continuously in one direction, the direction of current in the rotor must be switched at the right time as it turns. This switching is done either mechanically using a commutator and brushes, or electronically using sensors and switching circuits in a brushless coreless design.

Electromagnetic interaction: The rotor winding interacts with the stator magnetic field to create torque and rotation.

Commutation method: Brushes and commutator perform switching in brushed versions, while electronic commutation performs switching in brushless versions.

Low inertia behavior: Since the rotor has no iron core, it has low mass and low rotational inertia, so it speeds up and slows down quickly.

Smooth control: The motor can follow control signals with minimal lag, which is valuable for precise motion control.

In cinema systems, control accuracy matters more than raw power. A motor may need to move a camera 0.5 degrees and stop exactly, or adjust focus by a tiny amount without overshoot. Coreless DC motors support this because their low inertia and low inductance allow rapid changes in speed and torque. When integrated with feedback devices such as encoders or position sensors, they can produce highly repeatable motion profiles.

Coreless brushed motors often use a precious metal brush system and a small commutator. They can be efficient and simple, but brush wear is a consideration. Coreless brushless motors remove the brush system, improving life and reducing electrical noise, but they require a controller for commutation. Both types can be found in cinematic electronics depending on the product, size constraints, cost targets, and performance goals.

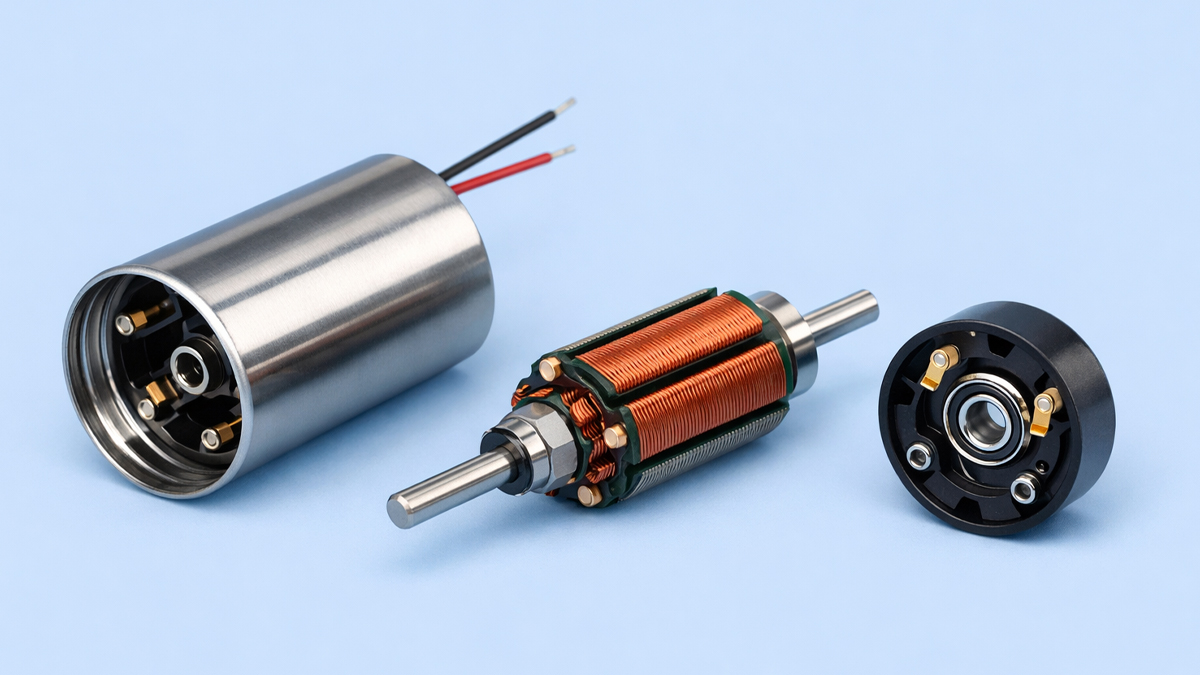

What are the Components of Coreless DC Motor?

A coreless DC motor has several key parts that work together to convert electrical energy into rotational motion with high responsiveness. Although details vary by manufacturer and type, the core components are fairly consistent.

Stator magnets: Permanent magnets fixed in the housing provide a strong magnetic field. High grade magnets improve torque density and responsiveness.

Rotor winding: A self supporting winding forms the rotating element. Instead of being wound around an iron core, it is formed as a hollow cylinder or basket structure.

Commutator: In brushed coreless motors, the commutator is attached to the rotor and provides segmented electrical contact points that switch current direction as the motor rotates.

Brushes: In brushed coreless motors, brushes provide sliding electrical contact to deliver current to the commutator. Brush material influences noise, wear, and efficiency.

Shaft: The rotor is mounted on a shaft that transmits torque to the load, such as a gear train, pulley, or direct drive mechanism.

Bearings: Bearings support the shaft and enable smooth rotation. Precision bearings reduce runout and vibration, which is crucial in cinema motion systems.

Motor housing: The casing holds magnets, bearings, and mechanical alignment. It also supports heat dissipation and structural stability.

End caps: End caps position bearings and sometimes hold brush assemblies, providing proper alignment and protection.

Terminals or leads: Electrical connections provide power input and sometimes feedback wiring for sensors in advanced assemblies.

Optional sensor system: Some coreless motors and integrated actuator modules include encoders, Hall sensors, or tachometers for speed and position feedback.

Optional gearbox: Many cinema devices pair a coreless motor with a planetary or spur gearbox to increase torque and improve resolution in positioning tasks.

Each component contributes to the motor’s behavior. For example, rotor winding geometry affects torque ripple and efficiency. Bearing quality influences acoustic noise and vibration, which can matter during sound recording. The magnet grade impacts torque output in a compact size. In cinema gear, motor choice is rarely isolated. It is usually part of a complete mechatronic system that includes driver electronics, feedback sensors, mechanical mounts, damping materials, and control software.

What are the Types of Coreless DC Motor?

Coreless DC motors come in multiple types, mainly distinguished by commutation method, construction style, and application integration. Understanding these types helps match the motor to a cinematic task.

Brushed coreless DC motor: Uses brushes and a commutator to switch current in the rotor. It is simple to drive and responds quickly. Brush wear and electrical noise are tradeoffs.

Brushless coreless DC motor: Uses electronic commutation instead of brushes. It often has longer life, lower maintenance, and lower electrical noise. It requires a controller and may use Hall sensors or sensorless control.

Ironless slotless motor: Often used as a broader category describing motors with no iron in the rotor and windings arranged to reduce cogging. Many coreless concepts overlap with slotless designs.

Self supporting basket winding motor: The winding is formed as a thin cylindrical basket. This is a classic coreless structure and is common in miniature and precision motors.

Flat coreless DC motor: Uses a pancake style geometry with a flat rotor winding. This can be useful when axial length is constrained and a thin motor profile is needed.

Integrated actuator module: A motor combined with gearbox, encoder, and sometimes a driver board into one compact package. This is common in cinema accessories where space and integration speed matter.

Precision micro coreless motor: Extremely small motors designed for low power and fine control, used in handheld devices, miniature camera rigs, and compact control mechanisms.

High torque coreless motor with gearbox: Designed for applications that need more torque than direct drive can provide, such as lens ring drives or compact slider mechanisms.

Each type suits different cinema needs. Brushed versions can be cost effective for short duty cycles and lighter loads. Brushless versions are preferred for professional gear that must run for long hours on set with consistent behavior. Flat designs can be useful in gimbal joints where packaging is tight. Integrated modules simplify design for equipment manufacturers and can provide reliable repeatability across units.

What are the Applications of Coreless DC Motor?

Coreless DC motors are used wherever fast response, smooth low speed control, compact size, and precise actuation are important. In general industries, they appear in medical devices, robotics, aerospace instruments, precision pumps, and consumer electronics. In cinema and media production, their applications are especially visible in motion control and camera support systems.

Camera gimbals and stabilizers: Coreless motors can drive gimbal axes or auxiliary mechanisms that adjust balance or provide precise corrections.

Follow focus systems: Motorized focus control systems rely on accurate torque and repeatable positioning, often using coreless motors with gear trains and encoders.

Zoom and iris control: Cine lens control for zoom and iris can use compact motors that deliver smooth motion without stepping artifacts.

Motion control rigs: Sliders, pan tilt heads, and programmable camera movement systems require motors that can follow motion curves and stop precisely.

Remote head systems: Professional remote heads may use coreless motors in fine adjustment subsystems or in compact actuators for auxiliary controls.

Camera cranes and jibs: Smaller auxiliary drives, counterbalance trimming, and control linkages can use coreless motors for fine positioning.

Autofocus modules in specialized rigs: Some camera systems and accessories use coreless motors for high speed focusing tasks.

Wireless lens control accessories: Motors integrated into compact wireless systems benefit from low inertia for fast, stable response.

Props and animatronics: Practical effects devices can use coreless motors for quiet, smooth movements that look natural on camera.

Audio gear mechanisms: In certain recorders or mixers, small coreless motors may be used for transport mechanisms or controlled actuators, where low vibration matters.

Drones used for cinematography: Some drone camera systems and payload mechanisms can use coreless motors in precision subsystems requiring lightweight actuation.

The main reason these applications benefit is simple. Film production often needs motion that is both precise and subtle. Coreless DC motors help create movements that are smooth enough to be cinematic rather than mechanical. When paired with proper control algorithms, they can generate slow creeping moves, gentle ramps, and repeatable trajectories that support storytelling.

What is the Role of Coreless DC Motor in Cinema Industry?

The role of a coreless DC motor in the cinema industry is to enable precise, smooth, and responsive motion in equipment that directly affects image quality, shot stability, and repeatability. In filmmaking, a motor is not just a machine that spins. It becomes part of the creative toolchain. The audience may never see the motor, but they see the result in the steadiness of a handheld shot, the elegance of a controlled focus pull, and the polish of a motion controlled move.

Smooth lens control: Focus, zoom, and iris adjustments must be controlled with finesse. Coreless motors can start and stop quickly while still allowing gentle slow motion when driven properly. This helps reduce visible jerks during focus pulls.

Stable camera support: Stabilizers and gimbals correct unwanted motion. Fast response is critical. Coreless motors with low inertia can react quickly to small disturbances, improving stabilization quality.

Repeatable motion control: Visual effects and multi take shots require the camera to repeat a movement exactly. Low lag and consistent torque improve the ability to match a programmed move across takes.

Quiet operation on set: Noise matters during dialogue recording. High quality coreless motor systems can be designed to operate with low mechanical noise and reduced vibration, especially when combined with proper bearings and mounts.

Compact integration: Cinema accessories must often be lightweight and compact. Coreless motors deliver high performance in small packages, allowing smaller rigs that remain ergonomic.

Better low speed control: Many cinematic movements are slow and deliberate. Coreless motor designs, especially slotless or ironless variants, can reduce cogging and produce smoother low speed rotation, which helps when creeping focus or gently panning.

Battery friendly performance: On location shoots, battery life matters. Efficient motors and optimized drivers can reduce power draw and heat, improving runtime.

Reliable creative workflows: A well controlled motor system makes the operator confident. That confidence translates into smoother takes and less wasted time.

In cinematic electronics, the motor is only one piece of the puzzle. The motor driver, the sensor feedback, the control loop tuning, and the mechanical coupling determine whether the final motion looks cinematic. Coreless motors provide a strong foundation for this because they are inherently responsive and lightweight. That allows the control system to make precise adjustments without fighting heavy inertia.

What are the Objectives of Coreless DC Motor?

The objectives of a coreless DC motor are tied to why the design exists in the first place. Removing the iron core aims to improve dynamic performance, reduce inertia, and enable more precise control. In cinema industry applications, these objectives align with creating smooth, responsive, and reliable motion.

High acceleration and deceleration: Enable the motor to reach target speed quickly and stop quickly, supporting rapid response in stabilization and control systems.

Low inertia operation: Reduce the rotational inertia so the motor follows control commands with minimal delay, improving precision.

Smooth low speed rotation: Reduce torque ripple and mechanical vibration, supporting cinematic slow moves and gentle adjustments.

High efficiency in compact size: Deliver useful torque and speed while keeping the motor small and lightweight, essential for portable rigs.

Accurate controllability: Provide predictable torque constants and electrical behavior to support closed loop control systems with encoders.

Reduced cogging tendencies: Many coreless or ironless designs minimize magnetic cogging, helping create smooth motion.

Support precise positioning: Enable fine angular positioning when paired with gearboxes and feedback sensors, useful for lens rings and pan tilt systems.

Lower mechanical vibration: Reduce vibrations that can show up as micro jitter in shots or create unwanted noise in audio.

Reliable integration into mechatronics: Fit into integrated modules that include sensors, gearboxes, and drivers, simplifying product design for cinema tools.

Consistency across operating range: Maintain stable performance across varying load conditions, temperatures, and battery voltage levels.

These objectives are not only technical. In cinema, technical performance becomes creative capability. A motor that can move smoothly at very low speed makes it easier to create an emotional, slow push in. A motor that can stop precisely makes it easier to match a visual effects plate. A motor that reacts fast helps stabilize chaotic handheld movement into a usable shot.

What are the Benefits of Coreless DC Motor?

Coreless DC motors deliver a set of practical benefits that make them attractive for cinematic electronics and precision motion devices. These benefits come from the rotor design, the magnetic circuit, and the resulting electrical and mechanical properties.

Fast response: Low inertia means the motor reacts quickly to changes in input voltage or control commands, improving stabilization and tracking.

High acceleration: The motor can spin up rapidly, supporting fast corrections in gimbals and quick focus transitions when needed.

Smooth motion potential: Reduced cogging and low torque ripple allow smoother slow speed operation, which is useful for cinematic moves.

High power to weight ratio: Coreless motors can provide strong performance in small, lightweight packages, which is essential for handheld rigs.

Efficient energy use: Many designs provide good efficiency for their size, supporting longer battery life in portable cinema equipment.

Lower inductance: Lower inductance supports faster current changes, which helps torque control and improves control loop performance.

Good controllability: Predictable torque constant and speed constant help engineers tune motor controllers for stable operation.

Compact packaging: Coreless motors fit into tight spaces inside lens motors, gimbal arms, and control handles.

Reduced heat in some regimes: Efficient operation can reduce wasted energy and heat, helping reliability and comfort for operators handling the gear.

Better feel for operators: Smooth motor behavior leads to more natural control feel in focus wheels and remote controllers.

When these benefits are combined with feedback sensors and high quality drivers, the motor becomes a precision actuator. In cinema, precision is not about being robotic. It is about being repeatable and invisible. The movement should support the story without drawing attention to the equipment.

What are the Features of Coreless DC Motor?

Features describe the typical characteristics you can expect from coreless DC motors. Not every motor has every feature at the same level, but the design family is known for specific traits.

Ironless rotor design: No iron core in the rotor reduces inertia and can reduce magnetic losses.

Self supporting winding: The rotor winding is formed as a structural element, improving dynamic response.

Low rotational inertia: Enables quick start, stop, and direction changes.

Low electrical time constant: Enables fast current response, supporting accurate torque control.

Smooth low speed capability: Many coreless designs can reduce cogging and improve smoothness when driven properly.

High efficiency in miniature sizes: Suitable for compact devices requiring precision.

High speed capability: Many coreless motors can reach high RPM, especially in direct drive applications.

Compatibility with gearboxes: Can be paired with precision gear trains for higher torque and finer positioning.

Option for feedback integration: Encoders and sensors can be integrated for closed loop control.

Multiple commutation options: Available in brushed and brushless variations to match performance and lifetime needs.

Low vibration potential: With good balancing and bearings, vibration can be minimized for stable imaging.

Scalable designs: Available in micro sizes for small accessories and larger sizes for more demanding actuators.

In cinematic electronics, features like smooth control and low inertia matter more than the headline speed rating. A motor that can deliver stable torque at low speed without hunting is often more valuable than one that can spin extremely fast.

What are the Examples of Coreless DC Motor?

Examples of coreless DC motor usage can be described through real world cinema related devices and typical subsystem designs. The goal here is to make the concept tangible without relying on brand specific claims.

Gimbal axis correction motor: A coreless motor can be used to make rapid small corrections to keep the camera level and stable while an operator moves.

Wireless follow focus motor: A compact coreless motor with gearbox can drive a lens focus ring smoothly, allowing a focus puller to control focus remotely.

Motorized slider carriage drive: A motion control slider can use a coreless motor to move the camera carriage along a rail with precise speed ramps.

Pan tilt head fine positioning: A remote head system can use coreless motors in fine adjustment channels to achieve smooth pan or tilt at very low speeds.

Iris control actuator: For certain cine lens setups, a motorized iris drive can use a coreless motor for gentle and repeatable aperture changes.

Compact camera rig accessory actuator: A small coreless motor can adjust a variable ND filter mechanism or a mechanical linkage in a controlled way.

Props and practical effects movement: A coreless motor can animate small prop elements, creating subtle motion that reads well on camera without obvious mechanical stepping.

Robotic camera repeat move: A programmable rig can use coreless motors in smaller joints or auxiliary axes to repeat movements across multiple takes.

Handheld stabilizer tuning mechanism: Some stabilizer accessories may use small motors for trimming balance or adjusting internal mechanisms.

Miniature dolly or tabletop rig: Small tabletop camera rigs can use coreless motors to create smooth tracking shots in tight spaces.

These examples show that coreless motors are often used where motion must be controlled delicately. In cinema, delicate motion is frequently the difference between a professional looking shot and a shot that feels amateur.

What is the Definition of Coreless DC Motor?

The definition of a coreless DC motor is a direct current motor in which the rotor armature does not use an iron core. Instead, the rotor consists primarily of a self supporting winding structure that rotates within a magnetic field produced by permanent magnets. By eliminating the iron core, the motor reduces rotor inertia and can improve dynamic response, enabling fast acceleration and precise control.

This definition highlights the key distinguishing point. The absence of the iron core is not a cosmetic change. It affects inertia, electrical characteristics, efficiency, and how the motor behaves under control. In cinematic electronics, that behavior is often the reason this motor is selected.

What is the Meaning of Coreless DC Motor?

The meaning of coreless DC motor is best understood as a motor design approach that removes the traditional iron core from the rotating armature in order to achieve faster and smoother performance. The word coreless refers to the missing iron core in the rotor. The motor still uses coils and magnetic fields to generate torque, but the rotor is lighter and can respond quickly.

In practical terms, the meaning is tied to performance outcomes.

Coreless means lightweight rotor, which means fast response.

Coreless means less inertia, which means better control.

Coreless often means smoother low speed behavior, which can make cinematic movements look more natural.

Coreless can also mean different tradeoffs, such as different thermal behavior because the winding may have less mass to absorb heat, and brushed versions may have brush wear concerns.

So the meaning is not only about construction. It is about why the construction matters, especially when precision motion is needed.

What is the Future of Coreless DC Motor?

The future of coreless DC motors in cinematic electronics is closely linked to trends in filmmaking technology, robotics, and portable production gear. Film production keeps moving toward lighter rigs, smarter stabilization, more automation, and more repeatable motion. These trends naturally increase demand for motors that are compact, responsive, and easy to control.

Growth in intelligent stabilization: Stabilizers are becoming more advanced, using better sensors and control algorithms. Coreless motors will continue to be useful because low inertia supports quick corrections and stable control loops.

More precise lens control ecosystems: Wireless lens control systems are improving, with better mapping, smoother torque delivery, and repeatability for complex shots. Coreless motors paired with high resolution encoders will remain important.

Integration and modularity: Manufacturers will keep integrating motors, gearboxes, and sensors into compact modules. This reduces setup time for crews and improves reliability in the field.

Improved brushless adoption: Brushless coreless designs may gain more adoption because they offer longer life and reduced maintenance, which matters for professional rental fleets.

Better motor driver electronics: Motor control chips and drivers will keep improving efficiency, torque control resolution, and noise performance. This will make coreless motors even smoother and more battery friendly.

Quieter operation requirements: Production sound standards remain high. Demand for low noise mechanisms will push designs toward better bearings, improved balancing, and refined control waveforms.

Miniaturization for compact cinema tools: Social media and independent filmmaking have increased the use of small cameras and compact accessories. Coreless motors fit well into small form factors.

More feedback driven systems: Closed loop control with encoders will become more common even in mid range gear, improving repeatability and reducing drift in motion.

Hybrid systems with AI assistance: As autofocus, subject tracking, and automated camera moves become more common, motor systems will need to execute control decisions quickly. Coreless motors provide the responsiveness needed for that execution.

Sustainability and efficiency: Efficient designs that reduce power consumption and heat will be favored, especially for battery powered field work.

The future is also about tradeoffs. As performance demands increase, designers must handle heat dissipation, mechanical resonance, electromagnetic interference, and durability. That means more attention to materials, winding techniques, and integrated thermal paths. For cinema, reliability is crucial. A motor that performs perfectly for a short test but fails after long shooting days is not acceptable. So the future will likely include improved manufacturing consistency, better quality control, and more robust integrated modules.

Summary

- A coreless DC motor is a DC motor with a rotor winding that has no iron core, making the rotating part lighter and more responsive

- Coreless motors work by electromagnetic interaction between the rotor winding current and the stator magnetic field, with commutation done by brushes or electronics

- Key components include stator magnets, self supporting rotor winding, shaft, bearings, housing, and in brushed designs brushes and a commutator

- Main types include brushed coreless, brushless coreless, flat coreless designs, and integrated actuator modules with gearboxes and sensors

- Common applications include gimbals, stabilizers, follow focus systems, zoom and iris drives, motion control rigs, and practical effects devices

- In the cinema industry, coreless motors support smooth lens control, stable camera movement, repeatable motion, compact design, and low vibration performance

- Objectives include fast response, low inertia, smooth low speed rotation, efficient compact power, and accurate controllability with feedback systems

- Benefits include high acceleration, smooth motion potential, good power to weight ratio, battery friendly efficiency, and improved operator control feel

- Features often include ironless rotor construction, low electrical time constant, compatibility with gearboxes, feedback integration options, and low vibration potential

- The future points toward more brushless adoption, better integrated modules, improved motor drivers, smarter stabilization, and increasingly repeatable automated cinema motion