What is Fast Recovery Diode?

A fast recovery diode is a specialized semiconductor diode designed to switch from conducting state to blocking state very quickly when the applied voltage reverses. In many power and high frequency circuits, a normal rectifier diode can continue conducting briefly after the voltage changes direction because stored charge inside the device must be removed. That delay is called reverse recovery. A fast recovery diode is engineered to reduce that delay, which lowers switching losses, reduces unwanted heat, and improves electrical cleanliness.

Fast recovery diodes are widely used in power electronics where switching happens at tens of kilohertz to hundreds of kilohertz, and sometimes higher. They support efficient conversion of electrical energy in systems like switch mode power supplies, motor drives, inverters, and high performance audio amplifiers. In cinematic electronics, these same power conversion blocks appear in digital cinema projectors, LED wall controllers, professional lighting drivers, camera power systems, and battery management accessories. Because cinema equipment often runs in environments where reliability, low noise, and stable power are essential, fast recovery behavior can directly improve performance.

Purpose: The core purpose of a fast recovery diode is to reduce reverse recovery time and reverse recovery charge so that the diode stops conducting quickly when it needs to, minimizing energy loss and electromagnetic interference.

Context: In modern cinema hardware, many circuits convert power efficiently at high switching frequencies to keep systems compact and cool, and fast recovery diodes help make those designs practical and dependable.

How does Fast Recovery Diode Work?

A diode conducts current primarily in one direction. When forward biased, it allows current to flow with a relatively small voltage drop. When reverse biased, it ideally blocks current. In the real world, when a conducting diode is suddenly reverse biased, it does not stop instantly because excess carriers remain stored in the junction and surrounding regions. These carriers must be swept out or recombined before the diode can fully block reverse voltage. During this brief period, a reverse current flows. That event is reverse recovery.

Reverse recovery behavior: Reverse recovery has two main parts. First, stored charge causes a reverse current spike as the circuit attempts to force current in the opposite direction. Second, the current decays until the diode regains its ability to block reverse voltage.

Fast recovery design: A fast recovery diode is designed with lifetime control and optimized junction profiles so stored charge is reduced and removed faster. This shortens reverse recovery time and reduces reverse recovery charge.

In a switching converter, the diode often alternates between forward conduction and reverse blocking rapidly. If reverse recovery is slow, the switching transistor must handle extra current at the moment of switching. That extra current creates power loss inside the transistor and the diode, increases heat, and can generate voltage overshoot and ringing in the circuit. A fast recovery diode reduces these problems by turning off quickly and smoothly.

Switching loss reduction: Less reverse recovery charge means less energy is dissipated during each switching event. Over thousands of switching events per second, the savings can be substantial.

Noise control contribution: Faster and more controlled recovery reduces harsh current spikes, which helps reduce electromagnetic interference that could otherwise affect sensitive audio, video, or control electronics used in cinema systems.

What are the Components of Fast Recovery Diode?

A fast recovery diode is a packaged semiconductor device, but it can be understood as a set of functional parts and engineered regions that determine its behavior.

Semiconductor junction region: The heart of the diode is the PN junction or a similar structure that allows current flow in one direction. Its doping profile is engineered to balance low forward voltage drop with fast recovery performance.

Drift region: Many power diodes include a drift region that supports high reverse voltage. The thickness and doping of this region influence blocking voltage, conduction loss, and recovery behavior.

Lifetime control features: Manufacturers often use techniques such as gold or platinum doping, electron irradiation, or other lifetime control methods to reduce carrier lifetime. This reduces stored charge, enabling faster turn off.

Metallization and contacts: Metal layers form low resistance electrical contacts to the semiconductor. Good contact design reduces conduction loss and improves thermal performance.

Passivation layer: A protective layer on the semiconductor surface reduces leakage current, improves reliability, and protects against contamination and moisture.

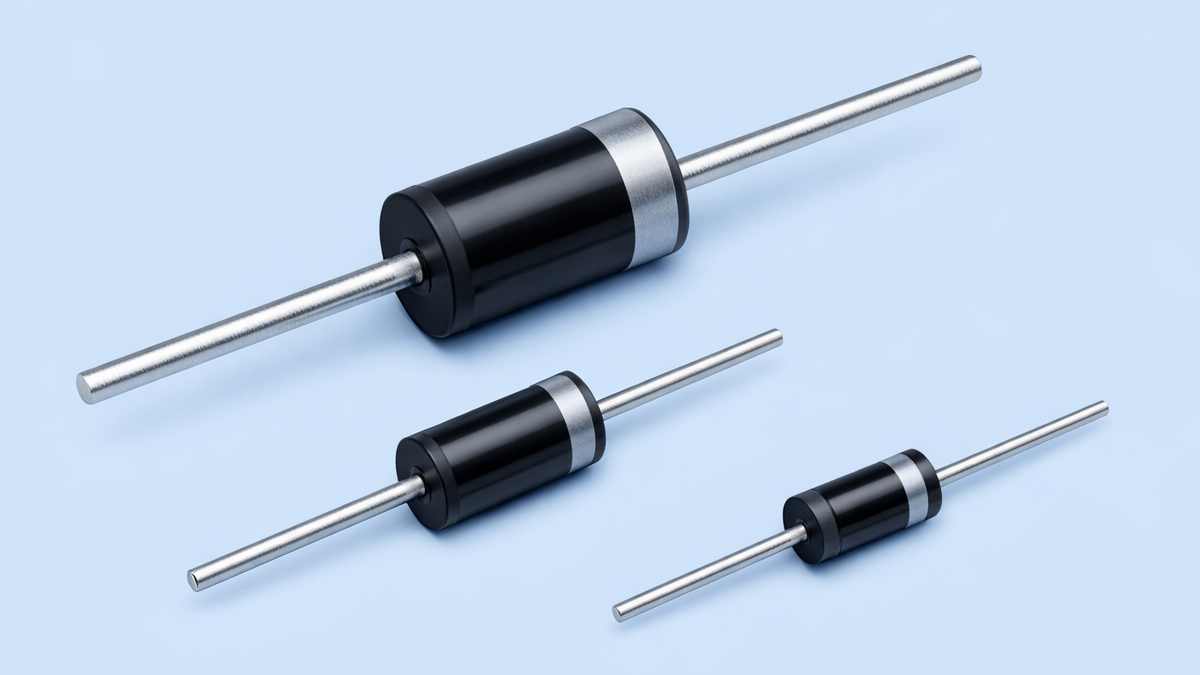

Package and leads: The diode is enclosed in a package such as DO 201, TO 220, TO 247, surface mount packages, or power modules. The package provides mechanical protection and electrical connections.

Thermal path: Heat must leave the junction and flow to the ambient environment. The internal die attach and package materials determine thermal resistance and influence safe operating limits.

Electrical parameters as functional building blocks: While not physical parts, specifications such as reverse recovery time, reverse recovery charge, forward voltage, leakage current, and maximum junction temperature effectively define how the diode behaves inside a circuit.

What are the Types of Fast Recovery Diode?

Fast recovery diodes come in multiple families, each tuned for particular tradeoffs between speed, voltage rating, current capability, and softness of recovery.

Ultrafast recovery diode: This type offers very short reverse recovery time, often used in high frequency switch mode power supplies, resonant converters, and power factor correction stages. The goal is maximum switching efficiency at high speed.

Fast recovery rectifier: This category targets a balance of speed and ruggedness. It is common in medium frequency converters, motor drives, and industrial supplies where reliability and cost matter.

Soft recovery fast diode: Soft recovery devices are designed so reverse recovery current decays more gradually, reducing high frequency ringing and electromagnetic interference. This can be valuable when sensitive analog or audio circuits share the same power environment.

High voltage fast recovery diode: These are designed to handle higher reverse voltages while retaining reasonably fast recovery. They are common in converters tied to higher bus voltages.

High current fast recovery diode: These focus on handling larger current pulses and continuous currents with adequate recovery performance and strong thermal design.

Related diode families in cinema electronics context: In some circuits, Schottky diodes are used when voltage ratings allow, because they have very low recovery charge. For higher voltage or higher temperature cases where Schottky is not suitable, fast recovery diodes become the practical choice.

What are the Applications of Fast Recovery Diode?

Fast recovery diodes appear anywhere a diode must switch quickly and efficiently. Their applications are strongly linked to modern power conversion and high frequency switching.

Switch mode power supplies: These power supplies convert AC to DC or one DC level to another using high frequency switching. Fast recovery diodes reduce losses in secondary rectification, snubber networks, and freewheeling paths.

Power factor correction circuits: Many PFC topologies use diodes that must recover quickly as switching occurs at high frequency. Efficient recovery supports lower heat and higher efficiency.

Inverters and converters: Fast recovery diodes are used in inverter output stages, DC DC converters, and auxiliary power rails. They help prevent excessive stress on switching transistors.

Motor drives: Variable frequency drives and servo systems use fast diodes as freewheeling and commutation elements. Reduced recovery improves efficiency and reduces noise.

Audio power amplifiers and power conditioning: Professional audio amplifiers and power distribution units can benefit from fast recovery rectifiers to reduce switching artifacts and power supply noise in certain designs.

Battery chargers and power management: High performance chargers often include switching converters where fast recovery diodes improve efficiency and thermal behavior.

Snubber and clamp circuits: In many switching systems, fast recovery diodes are used in clamp paths that catch energy from leakage inductance and prevent voltage spikes.

Reliability focused usage: In systems that run many hours continuously, such as cinema projection booths and large venue LED walls, lower losses mean lower temperatures, which can extend component life.

What is the Role of Fast Recovery Diode in Cinema Industry?

Cinema industry electronics includes digital projection, sound reinforcement, LED walls, studio lighting, camera systems, media servers, control networks, and power distribution. Many of these systems rely on high efficiency power conversion to remain compact, quiet, and reliable. Fast recovery diodes support that goal by making switching power supplies and high power drivers more efficient and electrically cleaner.

Digital cinema projectors: Projectors contain multiple power rails for light sources, imaging electronics, cooling systems, and control boards. Many rails are created by switch mode converters. Fast recovery diodes help improve efficiency and reduce heat inside the projector chassis, which supports stable performance and longer maintenance intervals.

LED cinema screens and LED wall controllers: LED panels and their drivers use high frequency switching to regulate current precisely. Fast recovery diodes can appear in driver stages, auxiliary supplies, and protection paths. Faster recovery helps maintain stable regulation and reduces electrical noise that could otherwise interfere with sensitive processing electronics.

Professional cinema lighting: Modern lighting instruments use switching drivers to control brightness, color temperature, and effects. Fast recovery diodes support efficient current regulation and help reduce electromagnetic interference that might disrupt wireless control, audio systems, or nearby cameras.

Audio and amplification systems: Cinema sound systems use high power amplifiers and power conditioning. While many amplifier power supplies are now switch mode, even linear supplies can benefit from carefully chosen rectification strategies. In switch mode power supplies for amplifiers, fast recovery behavior can reduce stress and improve transient response.

Camera and on set electronics: Cameras, monitors, wireless transmitters, and focus systems frequently use compact DC DC converters fed by batteries. Fast recovery diodes can improve efficiency, which can extend run time and reduce heat in small enclosures.

Media servers and networking equipment: Server racks, storage, and network switches rely on high efficiency power supplies. Fast recovery diodes contribute to lower losses and reduced thermal load, which supports stable operation in equipment rooms.

Noise and image integrity: Cinematic electronics must avoid visible artifacts, audio hum, or interference. Cleaner switching transitions and reduced ringing help maintain signal integrity for video processing, audio chains, and control networks.

Operational continuity: Cinema venues value uptime. Components that run cooler and with less electrical stress tend to be more reliable. Fast recovery diodes help reduce stress on switching devices and reduce heat, improving long term stability.

What are the Objectives of Fast Recovery Diode?

The objectives of using a fast recovery diode are primarily tied to performance, efficiency, and reliability in circuits that switch rapidly.

Minimize reverse recovery time: The first objective is to reduce the delay between forward conduction and full reverse blocking, enabling high frequency switching operation.

Reduce reverse recovery charge: Lower stored charge means less energy wasted during turn off and less current stress on switching transistors.

Improve power conversion efficiency: Reduced losses in the diode and the switching device raise overall efficiency, which is critical in compact cinema equipment.

Lower heat generation: Less switching loss means lower temperature rise, which supports reliability and quieter cooling solutions.

Reduce electromagnetic interference: Faster, controlled recovery reduces sharp current spikes that can radiate or conduct noise into sensitive audio, video, and control circuits.

Protect switching devices: By limiting reverse recovery current, fast recovery diodes reduce peak current stress and voltage spikes that can damage MOSFETs or IGBTs.

Support compact designs: High efficiency and lower heat allow smaller heatsinks and enclosures, which is important for portable rigs, compact projectors, and rack mounted cinema systems.

What are the Benefits of Fast Recovery Diode?

Fast recovery diodes deliver practical advantages at the system level, especially in high frequency or high efficiency power designs.

Higher efficiency: Reduced switching losses raise conversion efficiency, which lowers operating cost and improves energy use in always on cinema installations.

Lower junction temperature: Cooler operation increases component lifespan and reduces the chance of thermal runaway or degradation.

Reduced stress on transistors: Lower reverse recovery current reduces switching stress, improving reliability of MOSFETs and IGBTs used in power stages.

Better electrical cleanliness: Reduced ringing and spikes can improve overall electromagnetic compatibility, helping cinema systems coexist with microphones, wireless links, and sensitive video electronics.

Improved performance under dynamic loads: Power supplies that waste less energy in switching can respond more effectively to rapid load changes, which is useful in lighting effects, audio peaks, and projector subsystems.

Smaller cooling requirements: Lower heat can reduce fan noise, which is valuable in studios, screening rooms, and sound sensitive environments.

Better high frequency capability: Designers can operate converters at higher switching frequencies to reduce transformer and inductor size, leading to more compact cinema equipment.

What are the Features of Fast Recovery Diode?

Fast recovery diodes are characterized by a set of features that differentiate them from standard rectifiers.

Short reverse recovery time: This is a defining feature, enabling quick transition from conduction to blocking.

Low reverse recovery charge: Lower stored charge reduces the energy lost during switching and reduces stress on surrounding components.

Optimized forward voltage drop: Many designs balance speed and conduction loss so the diode has acceptable forward voltage while remaining fast.

High reverse voltage capability: Many fast recovery diodes are available in medium to high voltage ratings suitable for mains derived power stages.

Rugged surge handling: Power diodes often must tolerate inrush and transient currents. Many fast recovery families are designed with robust surge current capability.

Soft recovery options: Some devices are engineered for soft recovery to reduce noise and ringing, which is useful in cinema environments where EMI control is important.

Thermal stability: Fast recovery diodes are designed to operate reliably across wide temperature ranges with defined junction limits.

Package variety: Availability in through hole and surface mount packages allows use in compact camera rigs as well as high power projector supplies.

Measurement oriented features: Designers also consider leakage current, junction capacitance, switching softness, and dv dt ruggedness depending on the circuit topology.

What are the Examples of Fast Recovery Diode?

Examples in this context are best understood as common real world use cases rather than brand specific part numbers, because many manufacturers provide similar devices across different ratings.

Secondary rectifier in a projector power supply: A fast recovery diode can rectify high frequency transformer output into DC rails feeding imaging electronics, control boards, or cooling subsystems.

Freewheeling diode in an LED driver: In a current regulation stage for LED panels, a fast recovery diode provides a path for inductor current when the switching transistor turns off, maintaining continuous current and stable brightness.

Clamp diode in a lighting driver: In stage and cinema lighting, fast recovery diodes can be used in clamp circuits to limit voltage spikes and protect switching transistors, improving reliability during rapid dimming effects.

Auxiliary supply diode in a media server PSU: A fast recovery diode can serve in auxiliary rails that power standby logic, control circuits, and monitoring features while maintaining efficient switching.

Motor drive support diode in cinema automation: Motorized curtains, screen masking systems, and ventilation controls often use motor drivers. Fast recovery diodes help manage inductive current paths and reduce switching stress.

Design selection example: A designer might choose a soft recovery fast diode for an audio adjacent power rail to reduce high frequency noise, while selecting an ultrafast diode for a high frequency converter where maximum efficiency is the priority.

What is the Definition of Fast Recovery Diode?

A fast recovery diode is defined as a diode that has a significantly reduced reverse recovery time and reverse recovery charge compared to a standard rectifier diode, enabling it to switch off quickly when the voltage across it reverses. This definition emphasizes the diode ability to transition rapidly from forward conduction to reverse blocking in switching applications.

Key definition focus: The defining property is fast reverse recovery behavior, which directly affects switching losses, heat, and electromagnetic noise.

What is the Meaning of Fast Recovery Diode?

The meaning of fast recovery diode is practical and performance oriented. It means a diode that is suitable for circuits where switching happens quickly, and where slow turn off would waste energy or create electrical noise. In other words, it is a diode built for modern power electronics that operate at high frequencies and demand efficient, clean switching.

Meaning in system terms: It means improved efficiency, reduced heat, and reduced electrical disturbance in power conversion circuits.

Meaning in cinema terms: It means power supplies and drivers that run cooler, quieter, and more reliably in projectors, LED systems, lighting fixtures, and portable production equipment.

What is the Future of Fast Recovery Diode?

The future of fast recovery diodes is linked to broader trends in power electronics, including higher switching frequencies, higher efficiency targets, compact designs, and improved electromagnetic compatibility. Cinema technology is also moving toward more power dense systems such as brighter projection, larger LED displays, more advanced lighting, and more computing in media servers and real time rendering pipelines. These shifts increase the need for efficient power conversion and low noise electrical design.

Advancement in materials and structures: Improved silicon processing continues to refine carrier lifetime control and junction engineering, enabling lower recovery charge and better softness at higher voltages.

Competition and complement with wide bandgap devices: As silicon carbide and gallium nitride switching devices become more common, the surrounding power stage may shift toward diode solutions that match faster switching edges and higher temperatures. In some cases, silicon carbide diodes or synchronous rectification will reduce the need for traditional fast recovery silicon diodes, but in many cost sensitive and medium voltage rails, fast recovery silicon will remain a strong choice.

More emphasis on EMI performance: Future designs will prioritize soft recovery and reduced ringing to meet stricter electromagnetic compatibility requirements in dense cinema environments packed with wireless systems and digital processing.

Integration and module design: Power modules and integrated rectification stages may incorporate optimized diodes with better thermal paths, making installation easier and improving reliability.

Cinema industry direction: As LED cinema screens expand, projectors increase brightness, and real time processing becomes heavier, power systems will need to be highly efficient and thermally controlled. Fast recovery diode technology will continue to evolve as part of that ecosystem, either as discrete parts, integrated functions, or complementary elements alongside advanced rectification strategies.

Summary

- A fast recovery diode is a diode engineered to switch off quickly by reducing reverse recovery time and reverse recovery charge.

- Fast recovery behavior reduces switching losses, lowers heat, and decreases stress on power transistors in high frequency converters.

- Key internal elements include an optimized junction, drift region for voltage blocking, lifetime control techniques, and thermally efficient packaging.

- Common types include ultrafast recovery, fast recovery rectifiers, soft recovery versions, and variants optimized for high voltage or high current.

- Major applications include switch mode power supplies, inverters, motor drives, battery chargers, and clamp or snubber circuits.

- In the cinema industry, fast recovery diodes support efficient and reliable power for projectors, LED walls, professional lighting, audio systems, cameras, and media servers.

- Objectives focus on efficiency, EMI reduction, compact design, and long term reliability through cooler operation.

- Benefits include better energy efficiency, lower temperatures, improved electromagnetic compatibility, and more stable performance under changing loads.

- The future will be shaped by higher efficiency demands, EMI control, improved silicon processing, and the growing role of wide bandgap power technologies.