What is Ferrite Core Inductor?

A ferrite core inductor is a type of inductor that uses a ferrite material as its magnetic core to increase inductance and improve magnetic performance at medium to high frequencies. An inductor is an electronic component that stores energy in a magnetic field when electric current flows through it. The ferrite core inductor achieves this by combining a coil of conductive wire with a ferrite core, which concentrates magnetic flux and raises the coil’s effective inductance compared to an air core coil of the same size.

Ferrite is a ceramic-like magnetic material made primarily from iron oxide combined with other metal oxides such as manganese, zinc, or nickel. This composition gives ferrite high magnetic permeability and relatively high electrical resistivity. High permeability helps create a stronger magnetic field for a given current, and high resistivity helps reduce eddy current losses that become significant at higher frequencies. Because of these properties, ferrite core inductors are widely used in switching power supplies, radio frequency filtering, noise suppression, and many signal-conditioning circuits.

In the context of cinematic electronics under the cinema industry, ferrite core inductors appear in a wide range of equipment. They are found in digital cinema projectors, camera power systems, audio amplifiers, wireless microphone receivers, LED wall power distribution, motor drives for motion control, and networked control systems. Modern cinema environments are packed with high-speed digital signals and power conversion stages that can create electromagnetic interference. Ferrite core inductors are one of the key components used to keep power clean, suppress unwanted noise, and ensure reliable operation across sensitive audio, video, and control chains.

Purpose in practical terms: Store and release energy smoothly, filter current ripple, block high-frequency noise, and protect circuits from interference. In cinema systems where a single noise problem can become visible as flicker, audible as hum, or disruptive as dropped frames, ferrite core inductors contribute quietly but significantly to stability and performance.

How does Ferrite Core Inductor Work?

A ferrite core inductor works by opposing changes in current and storing energy in a magnetic field. When current flows through the coil, it creates a magnetic field around the wire. The ferrite core provides an easier path for magnetic flux than air, so the magnetic field becomes more concentrated within the core. This concentration increases inductance, which is the property that determines how strongly the inductor resists changes in current.

Electromagnetic principle: A changing current creates a changing magnetic field, and a changing magnetic field induces a voltage that opposes the change in current. This is the basic reason inductors smooth current ripple and act as filters. When current rises, the inductor generates a voltage that pushes back. When current falls, the collapsing magnetic field generates a voltage that tries to keep current flowing. This behavior makes inductors essential in power conversion, filtering, and energy storage.

Energy storage behavior: The inductor stores energy while current is flowing and releases it when the circuit demands it. This is especially important in switching power supplies, where energy is moved in short pulses. A ferrite core inductor helps transfer this energy efficiently by keeping losses low at switching frequencies.

Frequency behavior: At low frequencies, the inductor mostly behaves like a low-resistance coil that resists rapid current changes. At higher frequencies, its impedance increases, meaning it blocks high-frequency components more strongly. Ferrite materials are particularly useful at higher frequencies because their high resistivity reduces circulating currents inside the core that would otherwise cause heating and power loss.

Saturation behavior: Every magnetic core has a limit. If current becomes too high, the magnetic material can saturate, meaning it can no longer increase its magnetic flux proportionally. When saturation happens, inductance drops sharply, and the inductor becomes much less effective. For cinema systems, saturation can lead to unstable power rails, increased ripple, audible noise in audio paths, or erratic behavior in digital hardware. Designers select ferrite core inductors with appropriate saturation current ratings to keep operation stable even during load transients such as motor starts, sudden brightness changes in projection systems, or amplifier peaks.

Loss behavior: Real inductors also have losses from wire resistance, core hysteresis, and parasitic capacitance. Ferrite core inductors are chosen when the frequency is high enough that core choice matters, and when compact size and good filtering performance are important. In cinematic electronics, this is common because many devices rely on high-frequency switch-mode power supplies.

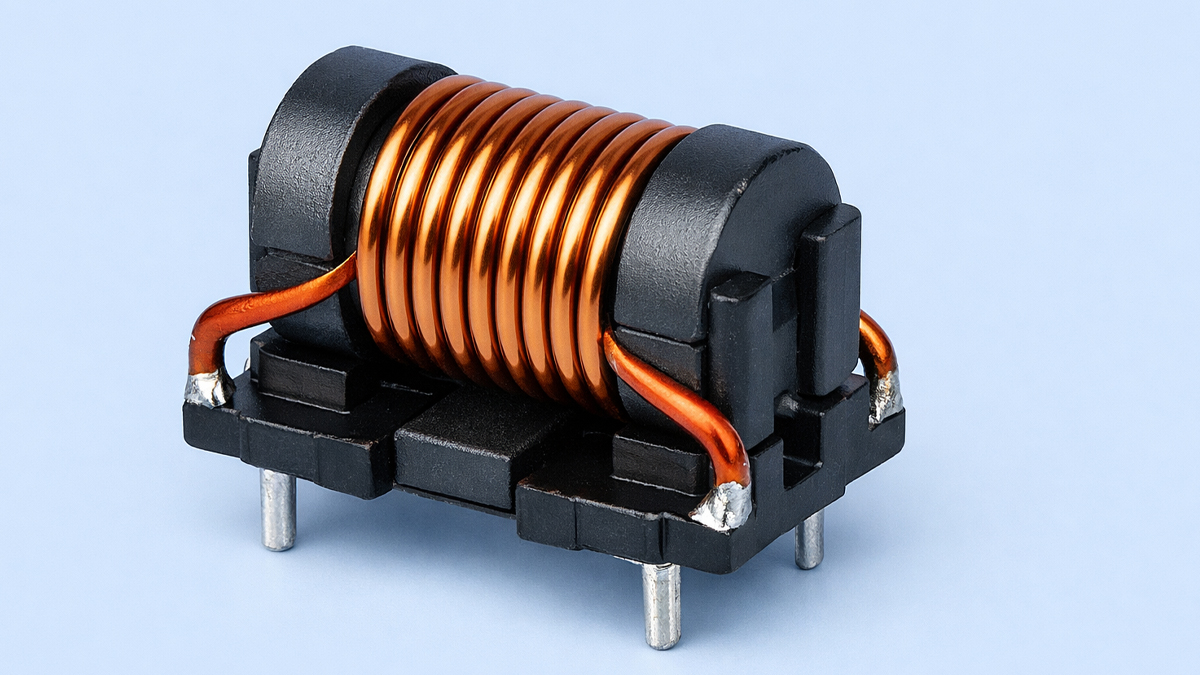

What are the Components of Ferrite Core Inductor?

A ferrite core inductor is built from a set of mechanical and electrical parts that work together. Each part influences performance, efficiency, noise behavior, and reliability.

Ferrite core: The magnetic material that concentrates magnetic flux and increases inductance. Ferrite can be formulated for different frequency ranges. Manganese-zinc ferrites are often used for lower switching frequencies, while nickel-zinc ferrites are often used for higher frequency noise suppression. Core geometry can be toroidal, E-core, pot core, rod core, or drum core, depending on the design goals.

Coil winding: The conductive wire wrapped around the core. Copper is most common. The number of turns, wire diameter, and winding pattern determine inductance, current rating, and resistance. More turns increase inductance but also increase resistance and size. Thicker wire reduces resistance and heating but increases bulk.

Insulation system: Enamel on the wire and additional insulation layers prevent short circuits between turns and between winding and core. Insulation quality matters for reliability, especially in equipment exposed to heat and vibration such as moving-head lighting power supplies, camera rigs, or touring cinema audio equipment.

Bobbin or former: Many inductors use a bobbin to hold the winding and define consistent geometry. Bobbins can improve manufacturability and provide isolation spacing. Some toroidal inductors wind wire directly on the core without a bobbin.

Terminations and leads: Through-hole leads, surface-mount pads, or wire leads connect the inductor to the circuit. Lead design affects mechanical robustness and high-frequency behavior. For cinematic equipment that experiences handling and transport, strong terminations reduce failure risk.

Core gap or distributed gap: Some inductors include an intentional air gap to increase energy storage capability and reduce sensitivity to saturation. Gapped ferrite designs are common in power inductors. Powdered iron cores provide distributed gaps naturally, but ferrite inductors can be designed with gapped cores when higher energy storage is needed.

Encapsulation and shielding: Some inductors use resin molding or a metal shield to reduce mechanical noise and electromagnetic radiation. Shielded inductors are helpful when an inductor sits near sensitive audio circuits, image sensors, or high-speed digital links common in cinema systems.

Parasitic elements: Even though not a physical part, parasitic capacitance and leakage inductance are real behaviors created by geometry. Designers manage these by winding techniques, spacing, shielding, and core selection. Good control of parasitics helps reduce ringing and electromagnetic interference.

What are the Types of Ferrite Core Inductor?

Ferrite core inductors come in several types, mainly distinguished by core shape, application, and construction style. Choosing the right type depends on frequency, current, size constraints, and electromagnetic compatibility requirements.

Toroidal ferrite core inductor: Uses a ring-shaped core. It offers excellent magnetic containment because the flux stays mostly inside the core. This reduces electromagnetic interference and makes toroids popular in audio power supplies and noise-sensitive circuits used in cinema sound systems and studio-grade equipment.

Drum core inductor: Common in compact power supplies. A drum-shaped ferrite core supports a winding around it. Drum cores can be unshielded or shielded. Shielded drum inductors reduce radiated noise and are frequently used in DC to DC converters inside projectors, media servers, and camera accessories.

E-core and I-core inductors: Built from ferrite pieces shaped like the letter E paired with an I piece. These are common in transformers and power inductors where a controlled air gap is included. They are used in higher-power applications such as larger power modules and industrial-grade cinema LED wall power distribution.

Pot core inductor: A ferrite core that encloses the winding more fully, helping shield the magnetic field and protect the coil. Pot cores are useful where low electromagnetic interference and compact packaging are required.

Rod core inductor: Uses a ferrite rod. These can be found in radio frequency circuits and antenna matching networks. In cinema environments, they may appear in wireless receiver front ends, RF filtering modules, and communication systems.

Chip ferrite inductors: Very small surface-mount components used for RF and high-speed signal conditioning. They appear in digital interfaces, clock distribution circuits, and high-speed processing boards used in cinema servers and camera systems.

Ferrite bead and ferrite choke: A ferrite bead is often placed over a conductor to suppress high-frequency noise. A ferrite choke is a form of inductor designed primarily for noise blocking rather than energy storage. In cinematic electronics, ferrite chokes are widely used on power input lines, HDMI and SDI interface boards, USB and Ethernet lines, and motor cables to reduce interference.

Common-mode choke with ferrite core: A special inductor where two windings share a core and suppress common-mode noise on a pair of conductors. These are critical in reducing conducted emissions on power and signal lines, supporting clean audio and stable video links.

What are the Applications of Ferrite Core Inductor?

Ferrite core inductors are used wherever designers need compact inductance, efficient filtering, energy storage, or electromagnetic interference control. Their applications spread across consumer electronics, industrial systems, communication hardware, and professional media equipment.

Switch-mode power supplies: Ferrite core inductors are central to DC to DC converters and AC to DC adapters. They smooth current ripple, store energy between switching cycles, and help regulate voltage. Cinema gear includes many switch-mode supplies, from projector power stages to camera battery systems.

Power conditioning and ripple filtering: Inductors work with capacitors to filter noise and ripple on power rails. Clean power is essential for high-resolution imaging sensors, digital signal processors, and precision audio circuits.

Electromagnetic interference suppression: Ferrite core inductors and ferrite chokes reduce high-frequency noise on cables and internal traces. This is essential in systems with high-speed clocks, wireless modules, and motor drivers.

Audio electronics: Inductors appear in amplifier power supplies, crossover networks, and noise filters. In cinematic audio, they help maintain low noise floors and reduce hum, especially where high-power amplification and sensitive preamps coexist.

RF circuits and communication systems: Ferrite inductors are used in tuning networks, matching circuits, filters, and impedance control. Wireless microphones, intercoms, and RF distribution systems in cinema and production environments rely on stable RF filtering.

Motor drives and motion control: Inductors reduce ripple and noise in motor control circuits. Motorized camera rigs, gimbals, lens controllers, and stage automation can use inductors for smoother power delivery and reduced electromagnetic emissions.

Data and signal integrity: Common-mode chokes and ferrite beads help keep digital interfaces stable by reducing conducted and radiated noise. This supports reliable video transport, control networks, and synchronization lines.

What is the Role of Ferrite Core Inductor in Cinema Industry?

In the cinema industry, ferrite core inductors support both performance quality and operational reliability. Modern cinematic electronics contain a dense mix of high-power conversion, high-speed processing, precision audio, and sensitive imaging. Each of these areas can suffer if power is noisy or if electromagnetic interference spreads through cables and enclosures.

Power stability in projection systems: Digital cinema projectors include multiple power rails for light engines, laser drivers, imaging chips, cooling systems, and control processors. Ferrite core inductors in their power conversion stages help deliver stable voltage and smooth current. This contributes to consistent brightness, reduced flicker risk, and fewer system resets during demanding scenes.

Noise control for cinema audio: Cinema sound systems handle very wide dynamic range. A small amount of power supply ripple or interference can become audible as buzz, hum, or hiss. Inductors and chokes in power supplies, amplifier modules, and signal interfaces reduce unwanted noise, helping maintain clarity from quiet dialogue to loud action sequences.

Electromagnetic compatibility in a crowded environment: A cinema hall includes lighting controls, HVAC systems, wireless microphones, network infrastructure, ticketing systems, and sometimes interactive displays. Ferrite core inductors and common-mode chokes help equipment meet electromagnetic emission limits and improve immunity to external noise. This reduces the chance that a motor start, a lighting dimmer, or a nearby radio transmitter will disrupt audio or video systems.

Signal integrity for digital video chains: Cinematic electronics often rely on high-speed digital links inside devices and between devices. Even when connectors and cables are high quality, interference can degrade margins and cause errors. Ferrite beads, common-mode chokes, and properly designed inductors help reduce noise coupling, improving robustness.

Reliability under continuous operation: Cinema equipment often runs for long hours in warm environments. Efficient inductors that minimize losses reduce heat, which improves longevity. Good inductor selection also reduces stress on capacitors and regulators, improving overall system reliability.

Support for portable and production gear: Beyond theaters, cinema production uses cameras, monitors, recorders, wireless systems, and battery-powered rigs. Ferrite core inductors in compact converters help deliver stable voltage from batteries while reducing noise that could affect sensors and audio recorders.

What are the Objectives of Ferrite Core Inductor?

The objectives of a ferrite core inductor describe what it is intended to achieve in a circuit, especially in systems that must be stable, quiet, and efficient.

Current smoothing objective: Reduce ripple and rapid fluctuations in current, particularly in switching regulators and power converters.

Energy storage objective: Store magnetic energy during part of a switching cycle and release it during another part, enabling efficient power conversion.

Filtering objective: Block or reduce high-frequency noise while allowing desired DC or low-frequency components to pass.

Impedance shaping objective: Provide a controlled impedance across frequency, helping stabilize circuits and prevent oscillations in regulators and amplifiers.

Electromagnetic interference reduction objective: Prevent noise from entering or leaving a system through power and signal lines, supporting electromagnetic compatibility.

Protection objective: Limit surge currents, reduce ringing, and help protect sensitive components from fast transients.

Size and efficiency objective: Achieve required inductance in a compact form factor with acceptable heat generation, which is important in tightly packed cinema electronics.

What are the Benefits of Ferrite Core Inductor?

Ferrite core inductors provide practical benefits that explain why they are so common in modern electronics and particularly useful in cinematic electronics.

High inductance in a small size: Ferrite’s high permeability allows designers to achieve higher inductance without making the coil large.

Good high-frequency performance: Ferrite materials are well suited for switching frequencies and noise suppression ranges used in modern power supplies and digital systems.

Lower eddy current losses: Ferrite has high electrical resistivity, which reduces internal circulating currents that would otherwise waste power and create heat at high frequencies.

Improved electromagnetic containment: Many ferrite core shapes and shielded designs reduce stray magnetic fields, lowering interference with nearby circuits such as audio preamps, image sensors, and RF receivers.

Better power efficiency: Reduced losses and effective filtering improve the efficiency of power conversion, which reduces heat and can improve equipment lifetime.

Cleaner audio and video operation: By reducing ripple and interference, ferrite core inductors help prevent audible hum, visible artifacts, and data link instability.

Design flexibility: Many core shapes, materials, and constructions exist, allowing optimization for power, frequency, noise, and mechanical constraints.

What are the Features of Ferrite Core Inductor?

Ferrite core inductors are characterized by specific features that engineers evaluate when selecting components. These features influence performance, reliability, and suitability for cinema-related systems.

Core material characteristics: Ferrite composition determines permeability, loss behavior, and useful frequency range. Material choice is a major design lever.

Inductance value and tolerance: Inductance is specified in microhenry or millihenry, with tolerance indicating how close the actual inductance is to nominal.

Saturation current rating: A key feature that indicates the maximum current before inductance drops significantly. In cinema power stages with sudden load changes, adequate saturation margin is essential.

Temperature rise and thermal rating: Inductors generate heat due to copper and core losses. Ratings and thermal design determine safe continuous operation.

DC resistance: The resistance of the winding affects efficiency and heat. Lower resistance improves power efficiency, especially in high-current supplies.

Quality factor: Often called Q, this indicates how efficient an inductor is at a given frequency. Higher Q is important in RF and some filtering applications.

Self-resonant frequency: At high frequencies, parasitic capacitance causes the inductor to resonate. Above this point, it may stop behaving like an inductor. Designers ensure the operating frequency is well below the self-resonant frequency for predictable behavior.

Shielding and EMI performance: Shielded inductors reduce radiated fields. Common-mode chokes and ferrite beads provide targeted suppression for specific noise paths.

Mechanical robustness: Package style, lead strength, and encapsulation affect durability under vibration and handling, common in production gear and touring cinema equipment.

What are the Examples of Ferrite Core Inductor?

Ferrite core inductors appear in many forms in real equipment. The examples below focus on how they show up in cinematic electronics without relying on brand-specific marketing names.

Projector power module inductor: A shielded ferrite drum core inductor used in a DC to DC converter that powers control boards, fans, or communication modules inside a projector.

Laser or LED driver filtering inductor: A gapped ferrite core inductor used to smooth current in lighting driver stages, supporting stable light output and reducing ripple that could cause flicker.

Cinema server motherboard ferrite beads: Small chip ferrite inductors used on high-speed power rails and signal lines to suppress noise near processors, memory, and network interfaces.

Audio amplifier supply choke: A toroidal ferrite core inductor used in the power input filter of an amplifier rack to reduce conducted noise and prevent switching supply artifacts from reaching sensitive stages.

Common-mode choke on network port: A ferrite core common-mode choke used on Ethernet lines in cinema automation and control networks to reduce interference and improve compliance.

Ferrite sleeve on cable harness: A ferrite core choke placed around a power cable feeding an on-set monitor or camera accessory to reduce high-frequency noise from a nearby converter.

Wireless receiver front-end inductor: A small ferrite core RF inductor used in matching or filtering networks that improve selectivity and reduce interference in wireless audio systems used for cinema production.

Motor controller inductor in a gimbal: A compact ferrite inductor used in a switching regulator powering motion control electronics, reducing noise that could couple into camera sensors or audio recorders.

What is the Definition of Ferrite Core Inductor?

A ferrite core inductor is an inductor that uses a ferrite magnetic core to concentrate magnetic flux, increase inductance, and improve performance at medium to high frequencies for purposes such as energy storage, filtering, and electromagnetic interference suppression.

What is the Meaning of Ferrite Core Inductor?

The meaning of ferrite core inductor can be understood in a simple, practical way. It means a coil component that becomes more effective and compact by adding a ferrite magnetic material inside or around the winding. The ferrite material strengthens the magnetic field produced by the coil and helps the component perform its main jobs, which are to resist rapid changes in current and to filter out unwanted electrical noise. In everyday engineering language, it is a compact magnetic tool that helps power and signal systems behave smoothly.

In cinematic electronics, this meaning becomes very visible in outcomes. Stable images, clean audio, reliable data links, and fewer interference-related issues often depend on quiet, well-filtered power and controlled electromagnetic behavior. The ferrite core inductor is one of the components that helps make those outcomes routine.

What is the Future of Ferrite Core Inductor?

The future of ferrite core inductors is closely tied to trends in power electronics, digital processing, and electromagnetic compatibility. Cinema technology continues to move toward higher efficiency, higher resolution, higher brightness, and more connectivity, all of which increase the need for better power conversion and noise control.

Higher switching frequencies and better materials: Power converters are often moving to higher switching frequencies to reduce size and improve transient response. This pushes inductors to operate efficiently at higher frequencies with lower core losses. Improved ferrite formulations and new processing methods will likely deliver better performance and lower heat for compact inductors.

Growth of wide-bandgap semiconductors: As power systems adopt devices like silicon carbide and gallium nitride, switching edges become faster and noise can increase if not controlled. This will increase the importance of carefully designed ferrite inductors, chokes, and beads for electromagnetic compatibility. Cinema systems that use high-efficiency power distribution and high-brightness light sources will benefit from these improvements.

More integrated power modules: Many electronics platforms are adopting integrated power stages where inductors may be embedded or co-designed with regulators. This can reduce parasitic effects and improve efficiency. In cinema servers, camera systems, and compact display electronics, integrated magnetics can support smaller, quieter, and more reliable designs.

Better shielding and lower acoustic noise: Inductors can sometimes produce audible noise due to magnetostriction and mechanical vibration, especially under pulsed loads. Future designs will emphasize mechanical damping, improved encapsulation, and optimized core structures to reduce coil whine and improve user experience in quiet cinema environments.

Sustainability and reliability focus: Cinema operators value uptime. Future ferrite core inductors may emphasize longer life under heat, better consistency across batches, and improved thermal performance. Manufacturers may also focus on materials and processes that reduce environmental impact while maintaining magnetic quality.

Smarter selection driven by simulation: Circuit simulation and electromagnetic modeling tools are becoming more accurate and accessible. This enables better selection and placement of inductors to minimize interference and improve performance. For cinema industry equipment, this will translate to more robust designs that maintain stable operation even in complex installations.

Summary

- A ferrite core inductor is an inductor that uses ferrite material to concentrate magnetic flux, enabling higher inductance and strong high-frequency performance.

- It works by storing energy in a magnetic field and opposing changes in current, which helps smooth ripple and filter noise.

- Key parts include the ferrite core, coil winding, insulation, bobbin or former, terminations, and sometimes shielding or a controlled air gap.

- Major types include toroidal, drum core, E-core, pot core, rod core, chip inductors, ferrite beads, ferrite chokes, and common-mode chokes.

- Common applications include switching power supplies, ripple filtering, electromagnetic interference suppression, audio electronics, RF systems, motor control, and signal integrity support.

- In the cinema industry, ferrite core inductors help maintain stable projector power, clean audio, reliable digital links, and better electromagnetic compatibility in complex environments.

- Objectives include energy storage, current smoothing, noise filtering, impedance shaping, interference reduction, and circuit protection.

- Benefits include compact size, reduced high-frequency losses, better efficiency, improved electromagnetic containment, and improved reliability in professional equipment.

- Important features include inductance value, saturation current, DC resistance, temperature behavior, self-resonant frequency, shielding performance, and mechanical robustness.

- The future points toward improved ferrite materials, better EMI control for faster switching power systems, more integrated designs, lower acoustic noise, and higher reliability for always-on cinema operations.