What is Powdered Iron Core Inductor?

A powdered iron core inductor is an inductor that uses a magnetic core made from tiny particles of iron that have been insulated from each other and pressed into a solid shape. This core sits inside or around a coil of wire. When current flows through the coil, the inductor stores energy in a magnetic field. The powdered iron core makes that magnetic field stronger than it would be with air alone, which allows the inductor to achieve useful inductance in a smaller size.

Material overview: The core is not a single solid piece of iron. It is a packed structure of iron powder particles, each particle coated with an insulating binder. This insulation creates many microscopic gaps throughout the core. Those distributed gaps help control how the core behaves at higher currents and at higher frequencies.

Why it matters in electronics: Inductors are used to smooth current, block noise, store energy in power supplies, and shape signals. Powdered iron core inductors are especially popular in switching power supplies and filters because they can handle significant current while remaining stable and predictable.

Where it fits in cinematic electronics: Cinematic electronics includes the power systems, lighting controls, audio systems, camera rigs, wireless gear, monitors, servers, and projection equipment used across the cinema industry. Many of these systems rely on clean, stable power. Powdered iron core inductors are one of the behind the scenes components that help deliver that stable power by reducing ripple and electrical noise.

How does Powdered Iron Core Inductor Work?

A powdered iron core inductor works by resisting changes in current. When current tries to rise quickly, the inductor creates a counteracting voltage that slows the change. When current tries to fall quickly, the inductor again produces a voltage that opposes the change. This behavior comes from the magnetic field that forms around the coil.

Magnetic field creation: When current flows through the coil, a magnetic field forms. The powdered iron core provides an easier path for magnetic flux than air, so the field becomes stronger for the same coil current. A stronger magnetic field means higher inductance, which increases the inductor ability to smooth current variations.

Energy storage: The inductor stores energy in the magnetic field while current flows. In switching power supplies used in cinema projectors, LED lighting drivers, and camera accessories, the inductor repeatedly stores and releases energy at high speed. This is a key part of converting voltage efficiently.

Distributed air gap behavior: The insulation between iron powder particles creates many tiny gaps. These gaps reduce the core effective permeability compared to a solid iron core, but they provide important advantages. The distributed gaps help prevent sudden saturation. Saturation is when the core can no longer support an increasing magnetic field, and inductance drops sharply. A powdered iron core tends to move toward saturation more gradually than many ferrite cores, which can be helpful in high current designs.

Heat and losses: Any real inductor has losses. Copper wire has resistance, which turns some energy into heat. The core also has losses related to magnetization. Powdered iron cores are often chosen for medium frequency switching ranges where they offer a good balance between cost, current handling, and loss.

What are the Components of Powdered Iron Core Inductor?

A powdered iron core inductor is built from a small set of key parts that work together to deliver the required inductance, current capability, and stability.

Copper winding: The coil is usually made from copper wire. The wire may be round, rectangular, or a flat strip depending on current needs. The thickness of the wire influences resistance and heating. Lower resistance generally improves efficiency and reduces temperature rise.

Powdered iron core: The core is formed by pressing insulated iron powder into a specific shape. Common shapes include toroids, cylinders, and blocks used with bobbins. The core material is selected based on frequency range, current level, and acceptable losses.

Insulation system: There is insulation on the wire itself, and sometimes additional insulation layers between winding layers. This prevents short circuits and helps the inductor meet safety and reliability standards.

Bobbins and formers: Many inductors are wound on a bobbin or former that holds the coil shape. Toroidal inductors often have the winding directly around the toroid without a separate bobbin, while other designs use a molded frame.

Leads and terminations: Through hole inductors use leads for soldering to circuit boards. Surface mount inductors use pads or metal terminations. The termination style affects mechanical strength and electrical resistance at the connection.

Protective coating or casing: Some inductors are coated with epoxy or placed in a molded case to protect the winding, reduce vibration issues, and improve durability in tough environments like touring cinema setups and mobile production kits.

What are the Types of Powdered Iron Core Inductor?

Powdered iron core inductors come in several forms, mainly distinguished by their core shape, mounting style, and intended use.

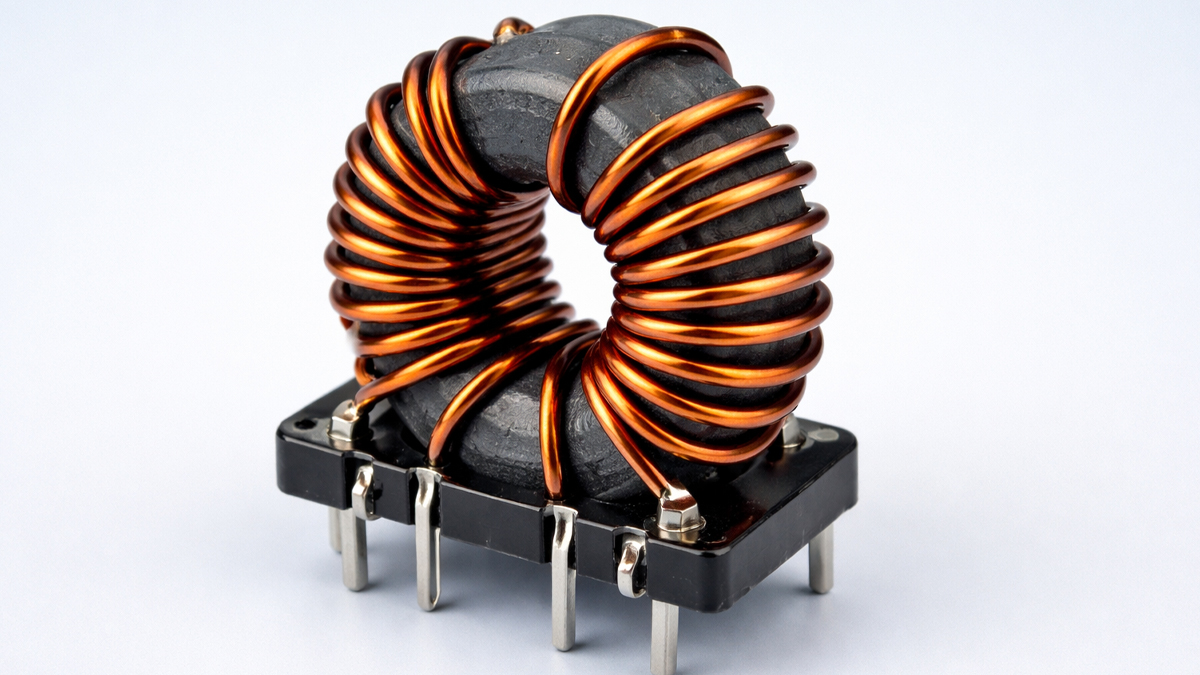

Toroidal powdered iron inductors: This type uses a ring shaped core. The winding wraps around the toroid. Toroids tend to keep magnetic flux contained within the core, which reduces electromagnetic interference. This can be useful near sensitive audio circuits or wireless receivers used in cinema production.

Drum core and molded inductors: Some powdered iron based designs appear as drum core inductors with a molded structure. Many modern power inductors use composite materials and molding methods to improve shielding and mechanical stability.

Rod core and axial inductors: These are commonly used in simpler filter networks. They may be found in legacy cinema equipment or general purpose power filtering boards.

Choke style inductors: A choke is an inductor designed mainly to block noise rather than store energy for conversion. Powdered iron chokes can be used on power input lines to reduce switching noise entering or leaving a device.

Power inductors for switching regulators: These are designed specifically for DC to DC converters. They are optimized for high current, low resistance, and stable inductance under load. This category is common in camera power accessories, monitor power boards, wireless transmitters, and control systems used around cinema sets.

What are the Applications of Powdered Iron Core Inductor?

Powdered iron core inductors are widely used wherever power conversion and filtering are required, especially where current is significant and stability matters.

Switching power supplies: Many cinema devices rely on switching power supplies to convert mains or battery voltage to stable rails. Inductors are central to buck, boost, and buck boost converters. Powdered iron cores are often used for their current handling and controlled saturation behavior.

Ripple filtering: Power supply outputs often contain ripple, which is a small AC component riding on DC voltage. Inductors, often paired with capacitors, reduce ripple. This helps protect sensitive circuits in digital audio processors, cinema servers, and camera electronics.

Electromagnetic interference filtering: Switching circuits can create high frequency noise that interferes with audio, communication, and control signals. Inductors can be used in EMI filters at power inputs and outputs to reduce conducted noise.

Audio power filtering: Audio amplifiers and processors benefit from clean supply rails. While audio paths use different kinds of inductors too, power filtering is a major use case. Cleaner power can reduce hum and background noise, which matters a lot in cinema sound.

Motor and actuator control: Some cinematic rigs use motors for focus control, gimbals, moving lights, and stage effects. Motor drivers often use inductors in their power stages to smooth current and control noise.

Battery powered equipment: Cameras, field monitors, wireless video systems, and portable recorders often use battery packs. DC to DC conversion is required to generate multiple voltage rails, and inductors are essential in those converters.

What is the Role of Powdered Iron Core Inductor in Cinema Industry?

In the cinema industry, reliability and signal cleanliness are not optional. A small power disturbance can cause audio noise, video glitches, device resets, or synchronization problems. Powdered iron core inductors support cinema systems by improving power quality, controlling noise, and enabling efficient energy conversion across many devices.

Power stability for projection and server systems: Digital cinema projectors and cinema servers contain complex electronics, including processors, memory, storage, networking, and high power light engine drivers. Their internal power supplies must handle varying loads without producing excessive ripple or noise. Inductors in these power supplies help keep voltage rails stable so image processing and playback remain consistent.

Cleaner audio environments: Cinema sound systems include amplifiers, digital signal processors, and mixing or routing hardware. Switching noise that leaks into audio rails can create hiss, whine, or hum. Inductors used in filtering stages help reduce this noise, supporting cleaner sound reproduction.

Lighting and stage control reliability: Modern cinema events and production environments often use LED lighting, dimmers, and intelligent control systems. LED drivers are switching power supplies at heart. Inductors help these drivers operate efficiently and reduce flicker, noise, and interference with control networks.

On set equipment performance: Cameras, monitors, follow focus systems, wireless video links, and timecode devices all depend on stable power, often from batteries. Power accessory boxes, voltage regulators, and distribution systems use inductors to step down or step up voltage. A well chosen powdered iron core inductor can help these systems deliver steady power even when loads change quickly.

Noise control near sensitive electronics: Wireless receivers, microphones, and high gain audio front ends can be sensitive to electromagnetic interference. Toroidal powdered iron inductors, with their contained flux, can help reduce stray fields compared to some other layouts, supporting better overall electromagnetic compatibility.

What are the Objectives of Powdered Iron Core Inductor?

The objectives of a powdered iron core inductor are practical goals that guide why engineers select and design them into a circuit.

Current smoothing: One objective is to reduce sudden changes in current. This is essential in power converters and filter networks.

Energy transfer in switching converters: In many power supplies, the inductor is the main energy storage element. It stores energy when the switch is on and releases it when the switch is off, helping convert voltage efficiently.

Ripple and noise reduction: Another objective is to reduce ripple on DC rails and to block high frequency switching noise from traveling through power lines.

Controlled saturation behavior: Powdered iron cores are often chosen to provide a more gradual inductance roll off with increasing current. This supports stable behavior in circuits that experience load changes.

Thermal management support: By enabling efficient power conversion and offering low losses in suitable frequency ranges, these inductors help reduce overall heat in equipment. Lower heat supports reliability in cinema environments where devices may run for long hours.

Electromagnetic compatibility: A key objective in professional cinema electronics is meeting EMI and EMC limits so that equipment does not interfere with other systems. Inductors help shape current waveforms and reduce noise emission.

What are the Benefits of Powdered Iron Core Inductor?

Powdered iron core inductors provide several benefits that make them useful in cinematic electronics and many other fields.

Good current handling: The distributed air gap allows the core to handle higher DC bias currents before inductance collapses, compared to many ungapped ferrite designs.

Predictable performance under load: Inductance tends to decrease more gradually with current, helping designers build stable power converters that behave well across operating conditions.

Wide availability and cost effectiveness: Powdered iron cores are common and often cost effective for many power designs, which matters when building equipment at scale.

Mechanical robustness: Many powdered iron inductors, especially toroids and molded types, can be physically robust and tolerant of vibration. This can be helpful in portable cinema rigs and on set gear.

Reduced stray magnetic field in toroidal designs: Toroidal powdered iron inductors tend to contain flux, which can reduce interference with nearby sensitive circuits.

Flexible design choices: Designers can choose from different mixes and permeability grades of powdered iron, supporting many inductance values and current targets.

What are the Features of Powdered Iron Core Inductor?

Powdered iron core inductors have identifying features that describe how they behave and how they are built.

Distributed gap structure: Instead of a single air gap, the core has tiny gaps throughout the material due to insulated particles. This feature strongly influences saturation behavior and inductance stability.

Moderate permeability: Powdered iron generally offers lower permeability than many ferrites, but the tradeoff is better energy storage capability and tolerance to DC bias.

Gradual saturation curve: Inductance typically reduces progressively as current increases, rather than collapsing suddenly. This feature is valuable in power regulation and current ripple control.

Frequency suitability: Powdered iron cores are commonly used in lower to medium frequency switching ranges. Their losses tend to increase at very high frequencies compared to some ferrite materials, so selection depends on switching frequency.

Variety of core shapes: Toroids, bobbin cores, and molded power inductors are available. This feature lets designers balance size, shielding, and manufacturing needs.

Temperature behavior: Like all magnetic components, performance changes with temperature. Powdered iron is often stable enough for many industrial environments when designed with adequate margin.

What are the Examples of Powdered Iron Core Inductor?

Examples help connect the concept to real cinema industry equipment and typical circuit locations.

Example in a projector power supply: Inside a digital cinema projector, there are multiple DC rails powering processors, fans, sensors, and control boards. A buck converter stage may use a powdered iron core power inductor to step down voltage while keeping ripple low.

Example in an LED cinema lighting driver: LED fixtures used in cinema events often rely on switching drivers to regulate current through LED strings. A powdered iron inductor can be part of the driver output filter, helping maintain steady LED current and reducing flicker.

Example in a camera battery plate regulator: Many camera setups use V mount or Gold mount batteries and then regulate the voltage down to 12 V, 7.4 V, or other rails. A compact molded inductor with powdered iron characteristics can be used in the DC to DC converter to handle load spikes when accessories turn on.

Example in audio equipment power input filtering: A cinema sound processor or amplifier may include an input choke as part of a conducted EMI filter. A powdered iron choke can reduce switching noise that might otherwise travel along power lines and enter sensitive audio circuits.

Example in a wireless video transmitter module: Wireless video systems need stable low noise power for RF stages and digital processing. Power regulation stages may use inductors chosen for predictable behavior and low interference, sometimes including toroidal powdered iron designs when layout permits.

What is the Definition of Powdered Iron Core Inductor?

A powdered iron core inductor is a passive electrical component that stores energy in a magnetic field using a coil of conductive wire and a magnetic core made from insulated iron powder particles pressed into shape, designed to provide inductance with controlled saturation and useful current handling for power conversion and filtering.

What is the Meaning of Powdered Iron Core Inductor?

The meaning of powdered iron core inductor can be understood by breaking the term into parts.

Powdered iron: The magnetic core material is iron in powder form, with each particle insulated to reduce unwanted electrical currents inside the core.

Core: The magnetic core guides and strengthens the magnetic field produced by the coil, allowing higher inductance in a smaller volume.

Inductor: The component resists changes in current and stores energy magnetically, commonly used to smooth power and reduce noise.

In simple terms, it means an inductor that uses a pressed, insulated iron powder core to improve energy storage and current handling in circuits, especially in power electronics used throughout cinema equipment.

What is the Future of Powdered Iron Core Inductor?

The future of powdered iron core inductors in the cinema industry is tied to trends in power density, efficiency, low noise performance, and compact design.

Higher efficiency power conversion: Cinema devices continue to demand more computing and higher brightness, which increases power needs. Power converters will keep improving efficiency to reduce heat and size. Inductors will be designed with lower resistance windings, better core mixes, and improved thermal paths.

More compact equipment: Cameras, monitors, wireless systems, and portable lighting are getting smaller while delivering more performance. This pushes inductor technology toward molded and shielded structures that fit tight layouts while controlling electromagnetic interference.

Improved EMI control: With more wireless systems on set and more digital audio processing, controlling interference becomes more important. Future powdered iron designs may emphasize better shielding, optimized winding geometry, and advanced composite materials that blend powdered iron properties with improved high frequency behavior.

Advanced materials and composites: Manufacturers are developing metal powder composites and specialized mixes that can deliver better losses, better saturation behavior, and improved temperature stability. Powdered iron concepts will remain relevant, even as materials evolve beyond traditional iron powder.

Integration into modules: Many power stages are moving toward integrated modules where inductors, capacitors, and switching controllers are packaged together. Powdered iron based inductive elements may increasingly appear as part of these integrated solutions, making cinema equipment more reliable and easier to manufacture.

Greater focus on reliability: Cinema systems run for long hours in theaters and in production environments. Future inductor designs will continue improving insulation systems, vibration resistance, and thermal durability to meet demanding duty cycles.

Summary

- Powdered iron core inductors use insulated iron powder particles pressed into a core to strengthen magnetic fields and provide stable inductance.

- They resist rapid current changes, store energy magnetically, and help smooth power rails in switching converters and filters.

- Key parts include copper windings, a powdered iron core, insulation, terminations, and often protective coatings or casings.

- Common types include toroidal inductors, molded power inductors, rod or axial styles, and choke oriented designs.

- Major applications include switching power supplies, ripple filtering, EMI filtering, motor control power stages, and battery powered regulators.

- In the cinema industry, they support projector electronics, cinema servers, audio systems, LED lighting drivers, and on set camera and wireless equipment.

- Benefits include good current handling, predictable behavior under load, cost effectiveness, mechanical robustness, and useful EMI performance in toroidal forms.

- Future development will focus on higher power density, improved efficiency, better EMI control, advanced composite materials, and more integrated power modules.